- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1000*150*500 mm

-

Weight:

-

60 KG

-

Product name:

-

Hot melt glue system

-

Usage:

-

automatic put the lable

-

Labeling type:

-

Double Face

-

Keyword:

-

glue gun machinery

-

Marketing Type:

-

Ordinary Product

-

Key words:

-

cartoning machine

Quick Details

-

Voltage:

-

220 50/60HZ

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

UPPER

-

Dimension(L*W*H):

-

1000*150*500 mm

-

Weight:

-

60 KG

-

Product name:

-

Hot melt glue system

-

Usage:

-

automatic put the lable

-

Labeling type:

-

Double Face

-

Keyword:

-

glue gun machinery

-

Marketing Type:

-

Ordinary Product

-

Key words:

-

cartoning machine

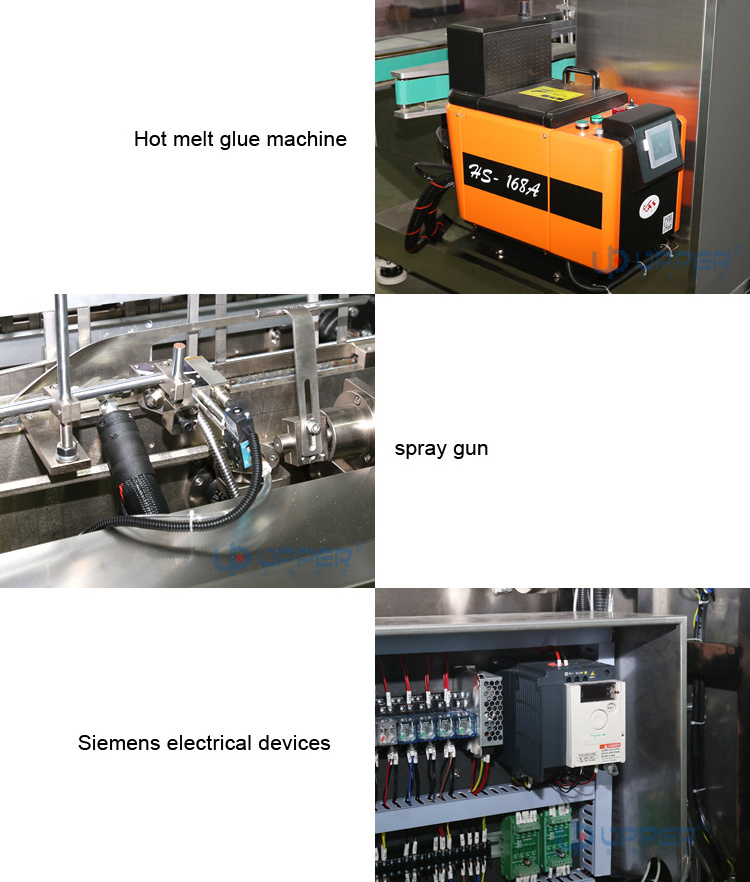

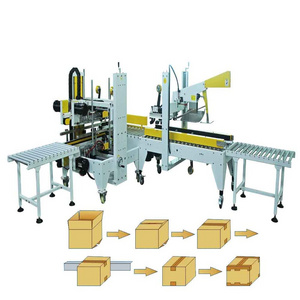

Automatic Hot melt glue system for carton box sealing

Application of hot-melt closure in Cartoner:

As a form of carton closure, hot-melt closure in Cartoner has partially substituted traditional tuck-in closure, and is applied in cartoning various foods and daily necessities. Due to the good packaging quality, pretty external appearance and low cost, hot-melt carton closure will expect wider application in Cartoning Machine.

1. Advantages of hot-melt carton closure

The hot-melt carton closure is bonded by cooling liquid hot melt adhesive from the hot melt adhesive mechanism that integrated with Cartoning Machine, which turns the hot melt adhesive into liquid and injects the liquid through its spray gun to the carton surface. It may both meet the requirements of carton closure in overall aspects and overcome the defects of other traditional carton closure.

2. Good packaging quality

Cartons to be transported must be able to withstand change of temperature and humidity as well as violent loading and unloading, but it is hard for tuck-in closure type to meet this requirement. Hot melt adhesive may bond well to cartons with strong permeability, so cartons sealed with hot melt adhesive are not liable to deformation or crack. Additionally, the application system of hot melt adhesive may press and apply the adhesive to key parts of various shapes, like the inner folded cover of cartons.

3. Anti-counterfeiting function

Hot-melt adhesive closure also provides anti-counterfeiting function, as the adhesive permeates into the carton and any attempt to open the carton will tear the fiber. However, for tuck-in type, it can be very easy to change articles contained in the carton and then close again without leaving conspicuous evidence.

The characteristics of this hot-melt system:

Modular and cost-conscious Concept C is suitable for melting and process-ing thermoplastic hot melt adhesives. Thanks to the modular design with different tank sizes, pumps and optional components, a variety of applications can be supported. The system can be extended at all times. Concept C is available with manual and automatic filling, is energy-op-timized and safe in its operation.

Easy installation and integration The melters are easy to install and access. Op-timized hose routing and a tank lid rotatable by 180° support any type of installation. Diverse interfaces and I/O signals are available for inte-gration and communication. Pattern control can be optionally integrated as well.

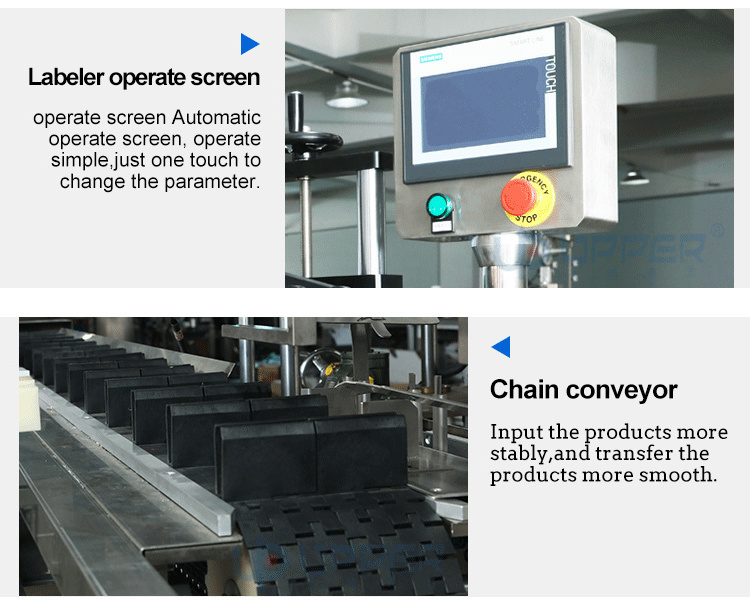

Language-independent operation

Operation is based on a language-indepen-dent control panel or an optional touchscreen. Using the additional InfoPlus software on the touchscreen, consumption and operation data can be collected and analyzed, e.g., for preven-tive maintenance.

Minimized maintenance effort

The tank is non-stick coated with FEP for ease of cleaning and the individual temperature con-trol prevents adhesive charring. In addition, fil-ters in tank and pump outlet minimize the risk of nozzle blockage.

Your advantages

> Modular design for flexibility and reduced costs with up to 2 connections for hoses and application heads

> Energy-efficient and safe thanks to CoolTouch insulation

> Easy integration, operation and maintenance

> Options, such as pattern control, level moni-toring, etc

Overview

Food, daily necessities, beverage group packaging, bowl noodles, milk tea, mosquito coils, wallpaper, exercise books, filters, electrical switches, plastic wrap, garbage bags, various stationery, industrial parts and daily cosmetics skin packaging, etc.