- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Y240418-34

-

Brand Name:

-

HYM

-

Product name:

-

Professional Precision Cnc Machining Parts

-

Material:

-

Customers' Requirement

-

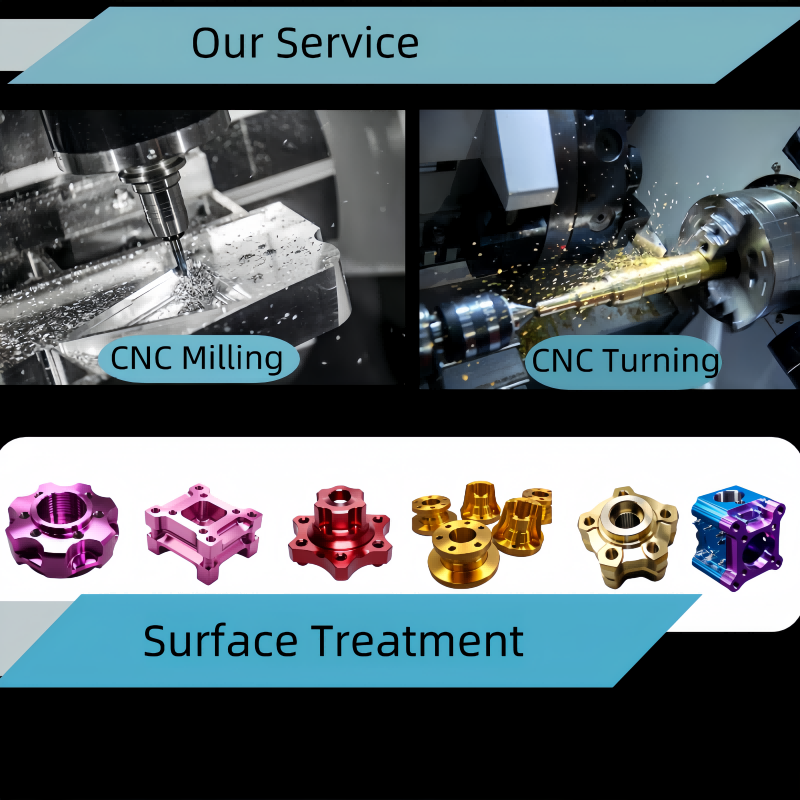

Process:

-

Cnc Machining + Surface Treatment

-

Surface treatment:

-

Customer's Request

-

Service:

-

Customized OEM ODM

-

Drawing Format:

-

2D/(PDF/CAD)3D(IGES/STEP)

-

MOQ:

-

Meeting Customer Requirements

-

Packing:

-

Plastic Bag+carton+pallet

-

Equipment:

-

3/4/5 Axis CNC Machining Center

-

Processing method:

-

Customer's Engineering Drawing

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys

-

Place of Origin:

-

Fujian, China

-

Model Number:

-

Y240418-34

-

Brand Name:

-

HYM

-

Product name:

-

Professional Precision Cnc Machining Parts

-

Material:

-

Customers' Requirement

-

Process:

-

Cnc Machining + Surface Treatment

-

Surface treatment:

-

Customer's Request

-

Service:

-

Customized OEM ODM

-

Drawing Format:

-

2D/(PDF/CAD)3D(IGES/STEP)

-

MOQ:

-

Meeting Customer Requirements

-

Packing:

-

Plastic Bag+carton+pallet

-

Equipment:

-

3/4/5 Axis CNC Machining Center

-

Processing method:

-

Customer's Engineering Drawing

Product Description

ALUMlMlNUM

Mlc6,2024,5052,6061-T6,6063,7050,7075-T6

STEEL

Alloys:

Stai nless steel(303.304L,316L,410,416,44oc,17-4PH)

OTHERS

Alloys;brass ,bronze ,copper

|

Processing

|

|

CNC Turning, CNC Milling, Laser Cutting, Bending, Spining, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection

Molding |

|

|

|||

|

Materials

|

|

Aluminum: 2000 series, 6000 series, 7075, 5052, etc.

|

|

|

|||

|

|

|

Stainlesss steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc.

|

|

|

|||

|

|

|

Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc.

|

|

|

|||

|

|

|

Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper

|

|

|

|||

|

|

|

Titanium: Grade F1-F5

|

|

|

|||

|

|

|

Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc.

|

|

|

|||

|

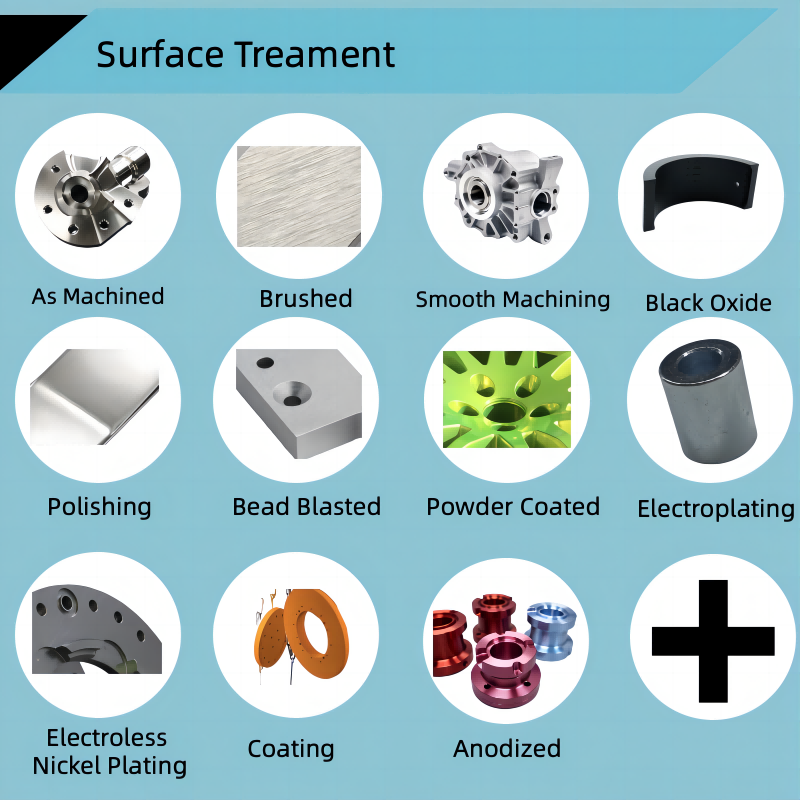

Surface Treatment

|

|

Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder Coated,

Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. |

|

|

|||

|

Tolerance

|

|

±0.002 ~ ±0.005mm

|

|

|

|||

|

Surface Roughness

|

|

Min Ra 0.1~3.2

|

|

|

|||

Surface Treatment

Production process

Drawing

Rawmaterial

CNC machining

Quality control

Packing

Finished

Our Advantages

CNC Turning

cnc. turning is a cnc process whera a cutting tool a typically non-rotating center removes material from a rotatting rigid material this process produces different shapes and sizes dep ending on the turning operations used.

CNC Milling

It is a computer-controlled process involving using a cutting tool to remove part of a workpiece. The basic setup involves placing

the workpiece on the machine’s table while the cutting tool/s attached to the spindle rotates and moves to shape the workpiece

into a finished product.

the workpiece on the machine’s table while the cutting tool/s attached to the spindle rotates and moves to shape the workpiece

into a finished product.

Gear hobbing

Wide adaptability: EDM can be used to cut all kinds of metal materials, including

This includes common steel and aluminum materials, as well as special materials with high hardness and melting point, such as titanium

Alloy, high-speed steel, etc. This is because electrical discharge machining does not rely on the hardness of the material and

The melting point can adapt to the cutting of different materials by adjusting the discharge parameters and processing technology

Cut demand.

QC Equipment

vernier caliper

Micrometer caliper

Roughness tester

2D projector

Height Gauge

Cmm

Company Display

Certificate management

We have been striving to exceed our customers' expectation in all aspects of product manufacturing, and recognize our great

responsibilities to our customers, suppliers, employees and society. Our mission is to create reliable, viable and affordable

molds, precise parts and fast sample service for every customer. It is precisely because of our precise processing, competitive

prices and satisfactory customer service that our products have been exported to more than 30 countries around the world.

Application Areas Of Some Of Our Parts

Machinery

Vehicle

Medical

Aerospace

Robot

Appliance

FAQ

1.How can I get CNC parts sample?

Yes, just need sample cost, we will return it back in mass production.

We also provide free samples in special conditions.

We also provide free samples in special conditions.

2.How about the lead time?

It depends on quantity, generally 7-20 days after order confirmation.

3.Can you give me help if my products are very urgent?

Yes, we will try our best to give you help. Because we have our own factory to produce. We can flexible to adjust our production schedule.

4.I want to keep our design in secret, can we sign NDA?

Sure, we will not display any customers' design or show to other people, we can sign NDA.

5 .Can we know the production process without visiting the factory?

We will offer a detailed production schedule and send pictures and videos which show the machining progress.

Hot Searches