- Product Details

- {{item.text}}

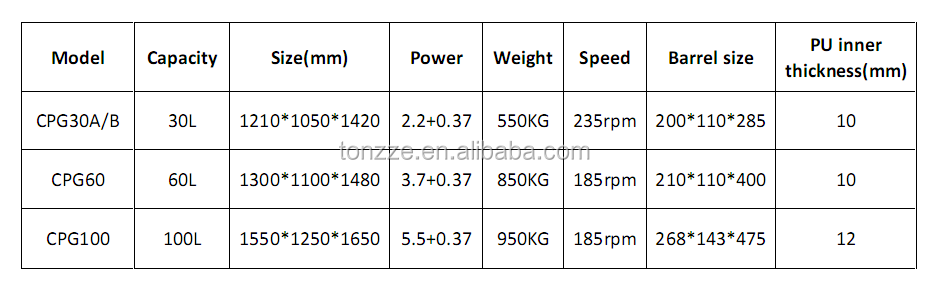

Quick Details

-

Type:

-

metal processing machine

-

Power:

-

1.5 kw

-

Size (L*W*H, mm):

-

1000*1000*1200

-

Capacity:

-

7.5*4 L

-

Weight:

-

350 kg

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Tonzze

-

Color:

-

blue and greyish white

-

Type:

-

metal processing machine

-

Power:

-

1.5 kw

-

Size (L*W*H, mm):

-

1000*1000*1200

-

Capacity:

-

7.5*4 L

-

Weight:

-

350 kg

1. Structure:

Tonzze centrifugal finishing machines consist of shell, assembly of drums and turn-plates, electrical box, motor and base.

Shell: made of steel plate. Each ending has a louver; a cover which can be opened and closed is fixed in the front of the shell. To be safe, on the frame of the cover a position switch is equipped. When the cover is opened, the machine switches off, and the disks stop.

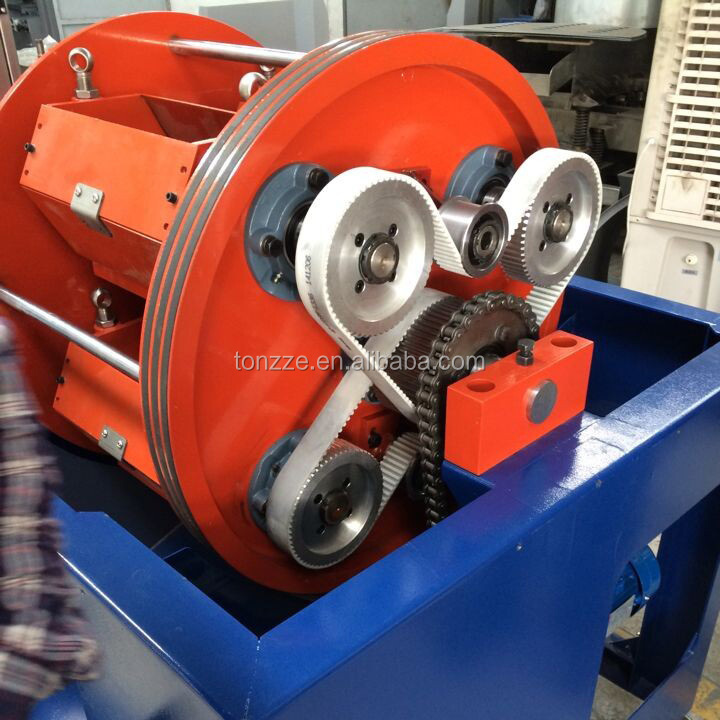

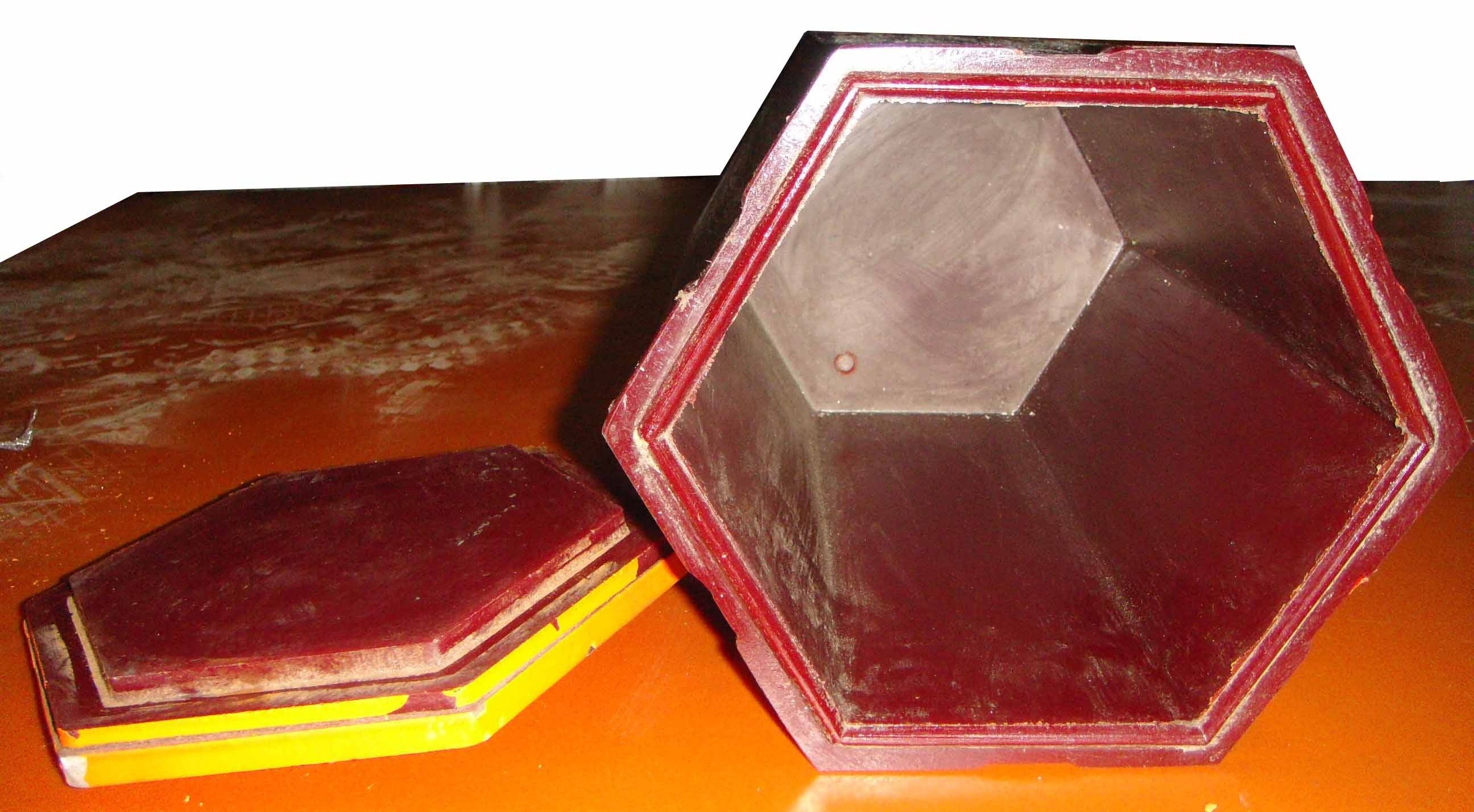

Assembly of drums and turnplates: consist of belt pulley, 2 turnplates, fixed main shaft, sheath, gear sets, 4 drums and locking device.

Electrical box: made of cold-roll steel plate. It is fixed on the side of the shell. All CE certificated and good quality components are in the box and the control panel is on the front side of electrical box.

Motor: Motor provides power to run the turnplates and drums. It is in the base and under the turnplates.

Base: made of steel plate. A motor board is fixed in the steel tank on the bottom. The motor board can be moved up and down along the screw to adjust the motor belt. The shell and the assembly of drums and rotator disks are fixed on the base.

2. Function:

The centrifugal grinding machine has a good effect of de-burring, chamfering, polishing and cleaning the work-pieces in a short time; and it can almost reach a mirror polishing. Best for smooth metal parts surface finishing. The speed is adjustable.

3. Working Principle

The turnplates with four drum bases offset equidistantly in the centrifugal machine orbits around the central main bearing in high speed, It produces powerful centrifugal force while it is turning around; at the same time the four planetary hexagonal drums are driven to spin reversely by the timing belt or nylon gears, making the grinding stones and work-pieces in the drums move and grind or finish each other.

4. Packing details.

The whole machine will be packed in a firm plywood case for shipping.