- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

INNOVACERA

-

Metallization:

-

Mo/Mn metallization,Ni Plating

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Fujian, China

-

Model Number:

-

INCM02

-

Brand Name:

-

INNOVACERA

-

Metallization:

-

Mo/Mn metallization,Ni Plating

|

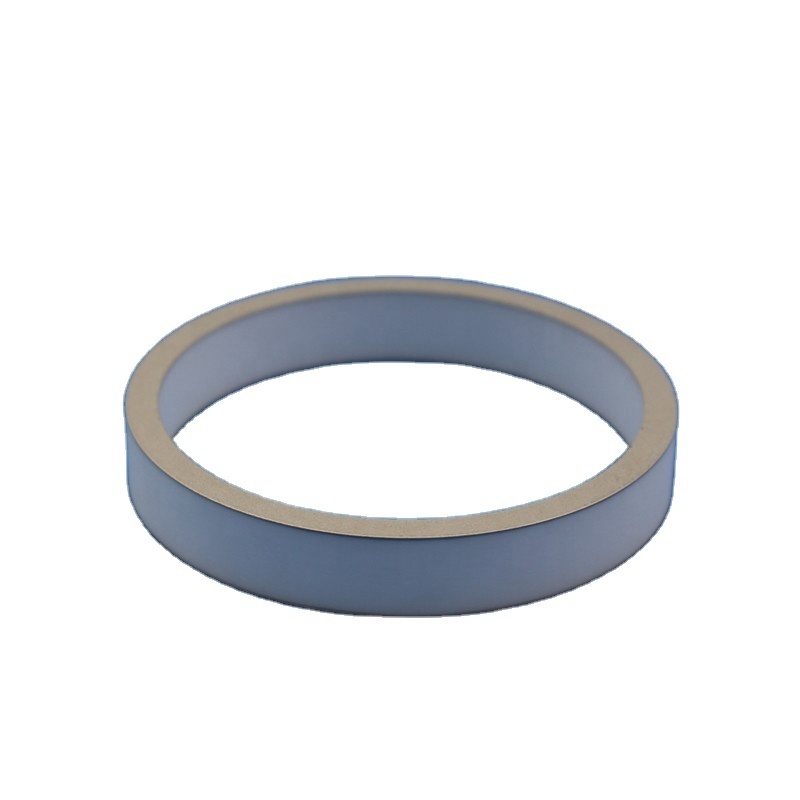

Product Name

|

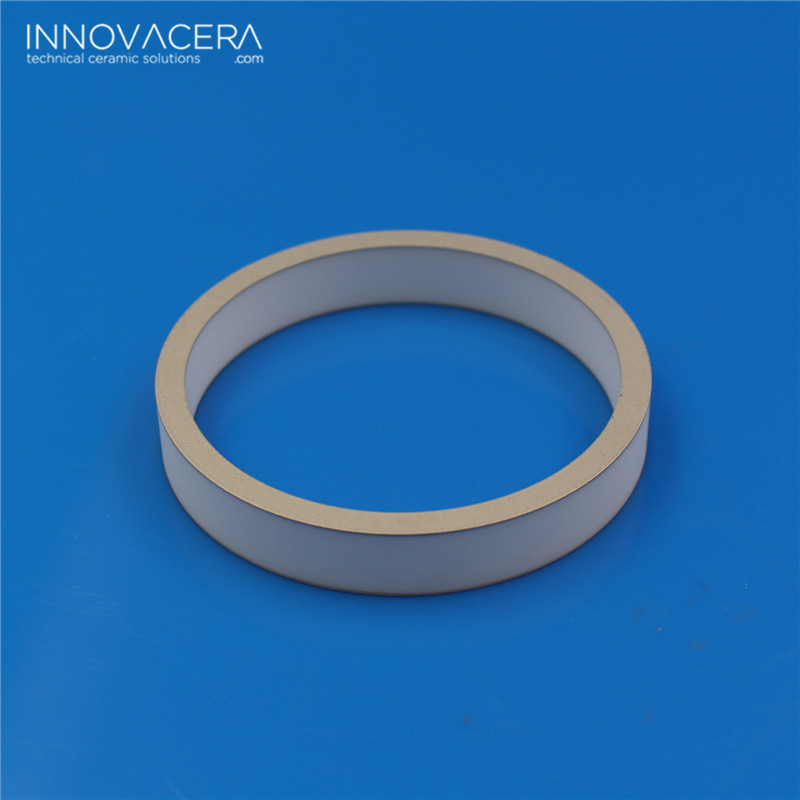

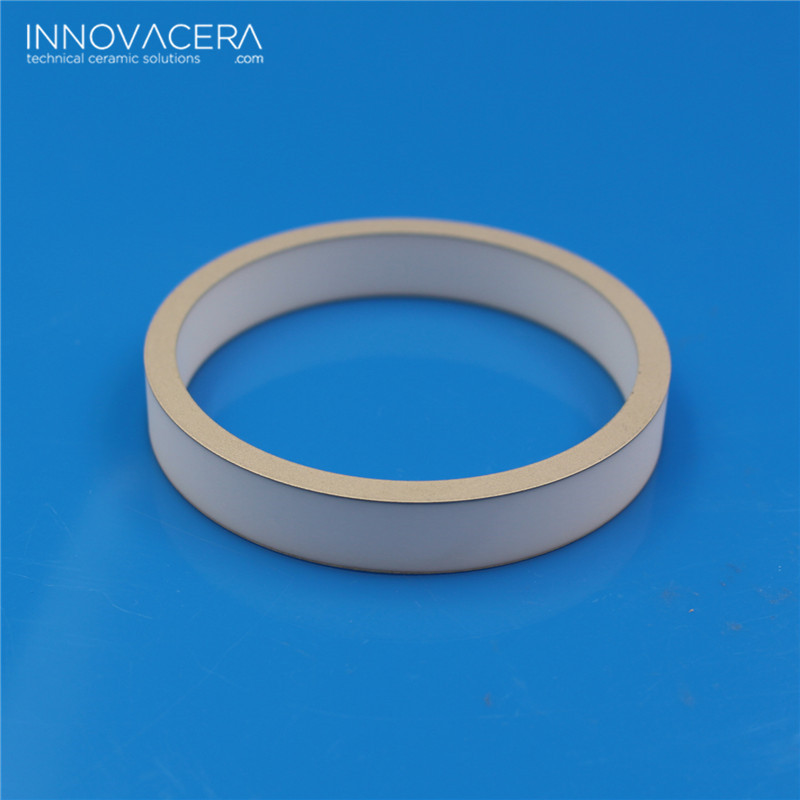

Mo/Mn Metallized Alumina Ceramic Seal Ring

|

|

Material

|

96% Alumina (AL2O3)

|

|

Color

|

White+Metal

|

|

Coaing Layer

|

Mo/Mn

|

|

Coaing thickness

|

8-30um

|

|

Plated Layer

|

Ni,Cu,Au,Etc

|

|

Plating thickness

|

3-9um

|

|

Brade

|

INNOVACERA

|

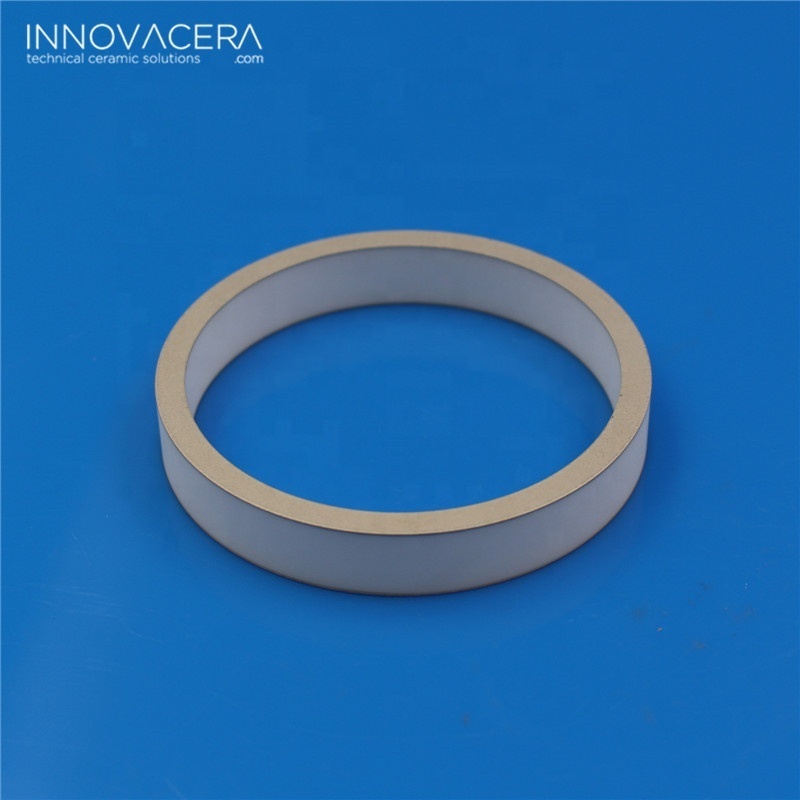

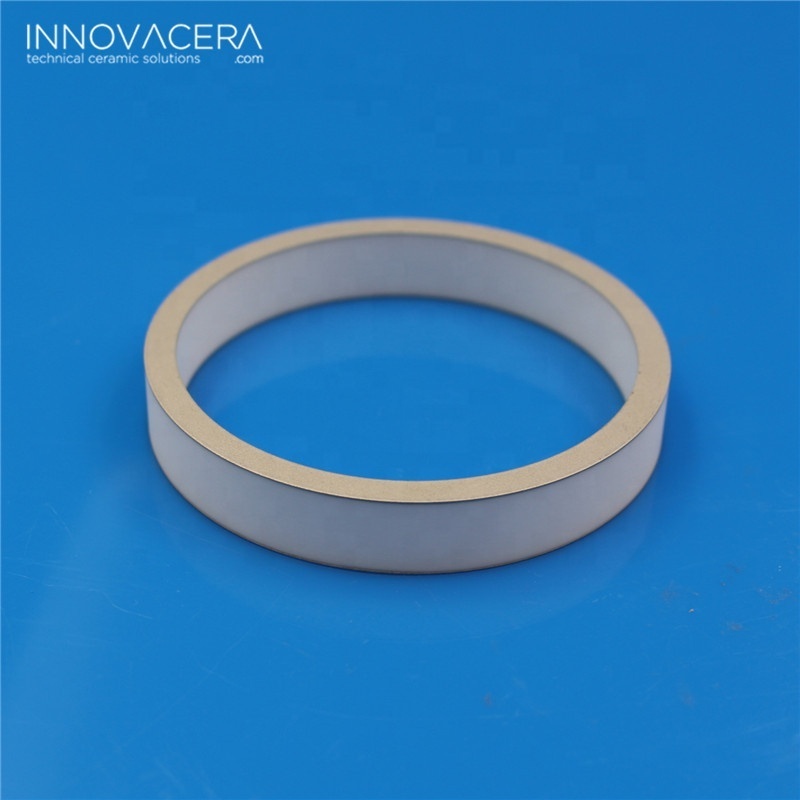

So far the most widely-used and effective method for creating a leak-tight, robust joint between ceramic and metal is by brazing . A thin layer of metal deposited on a ceramic part enables brazing between ceramic and metal part that has a different coefficient of thermal expansion.

A layer of Molybdenum-Manganese is deposited with a typical thickness of 8 to 30 µm after sintering.

The metallized surface receives a secondary coating of nickel to seal and improve wettability for later brazing.

Electrical transmission and distribution

Electronics industry

Textile machinery

Automobile industry

Sealing

Solid Oxide Fuel Cells

High temperature application

We can supply the products according to customer's drawings, samples and performance requirement.

metallized ceramics for vacuum interrupters,metallized ceramics for electrical and electronic devices, ceramic brazed components, ceramic metallizing, welding ceramic part.

Factory

Workshop

Our Workshop

Warehouse

Our Warehouse

Team

Our Team

Packing Details : Carton/Wooden Box With Foam /Vacuum package or pack as customer's requirement.

Delivery Details : 3-45 days after payment,,depend on actual quatity.

Q1: How to send an inquiry

Q2:Can you provide the free samples ?

Yes,we can provide the sample free of charge if we have the stock product as customer's required,but the courier fee be collected.

Q3:How long will it take for you to send me a quote?

This depends on the complexity of your requirements. For simple items such as plates and rods, we can generally supply a quotation within 24 hours.

Q4:What's the delivery time?

For the standard products, like ceramic substrate and insulating rods, delivery time is normally 7 working days. For hot pressed boron nitride and machinable glass ceramic, it's about 10 working days. For customized products made of alumina, zirconia, boron carbide and silicon nitride, total producing time is about 30-45 working days.

Q5:How to contact us ?

You can send the email to aria (at) innovacera.com.

Call to +86 0592-5589730