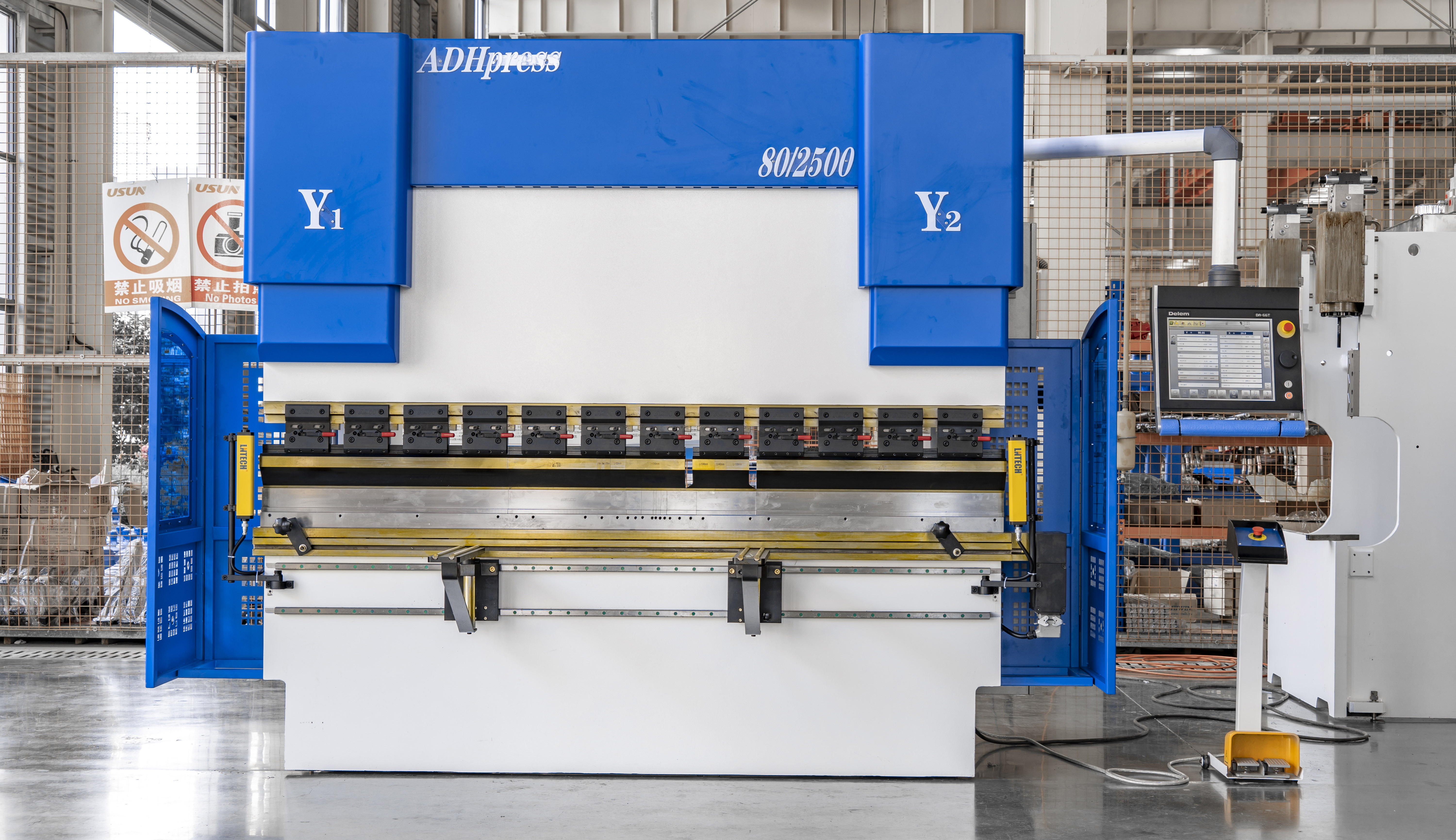

· electro hydraulic servo system

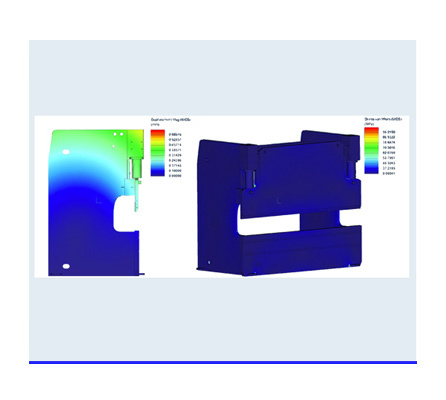

· mechanical compensation

· servo mo-tor back gauge

|

Model

|

80T/2500

|

|

Bending Force

|

800 (KN)

|

|

Bending Length

|

2500 (mm)

|

|

Oil Tank

|

170 (L)

|

|

Aprroaching Speed

|

220 (mm/S)

|

|

Ram Speed

|

12 (mm/S)

|

|

Return Speed

|

145 (mm/S)

|

|

Column Distance

|

2050 (mm)

|

|

Throat Depth

|

300 (mm)

|

|

Stroke

|

150 (mm)

|

|

Dimensions

|

3100*1600*2600 (L×W×H mm)

|