- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220v 380v 440v and customized

-

Power:

-

customized

-

Dimension(L*W*H):

-

upon customer's drawings

-

Weight (KG):

-

14000

-

Product name:

-

Foundry Automatic Green Sand Molding Machine

-

Quality:

-

High Level

-

Function:

-

Sand Foundry Molding

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Machine Type:

-

automatic sand core making machine

-

Brand Name:

-

LIONSTECH

-

Voltage:

-

220v 380v 440v and customized

-

Power:

-

customized

-

Dimension(L*W*H):

-

upon customer's drawings

-

Weight (KG):

-

14000

-

Product name:

-

Foundry Automatic Green Sand Molding Machine

-

Quality:

-

High Level

-

Function:

-

Sand Foundry Molding

The whole system consisting of the following components:

Mixer

Cold box sand core molding machine

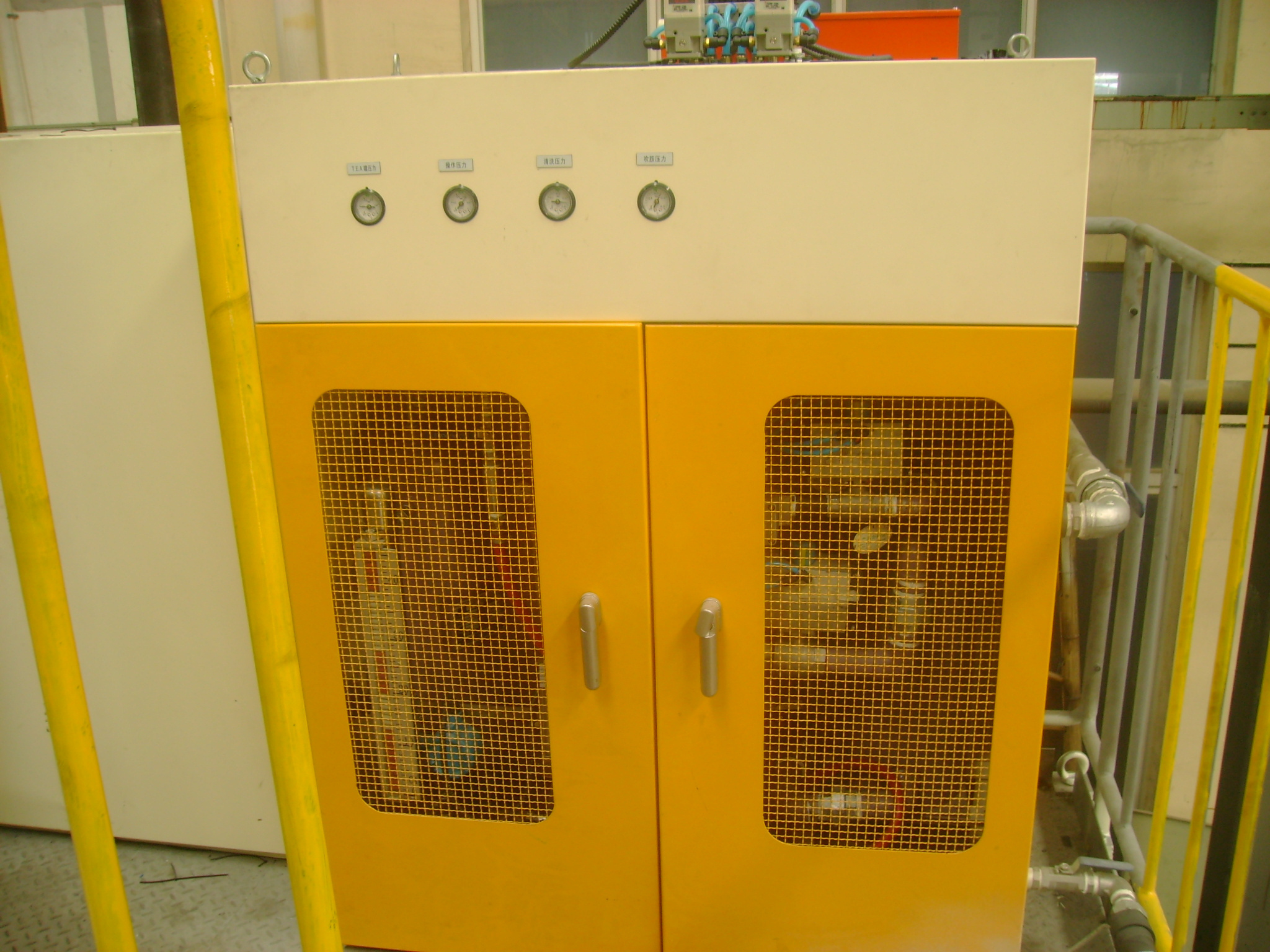

Gas generator

Exhaust gas disposer

Mold

And eligible sand core is the checking standard when receiving the machine.

Gas involved in solidification including C 6 H 15 N, CO 2 , HCOOH and SO 2 .

Features

·Able to make 2-station and multi-station sand core molding machine

·Patented shooting mouth technology

·Different molds alternately used in one machine to generate more than one kind of product

·Extra large size of shooting head allows for huge size of sand cores

Q1. Where is your factory located? How can I visit it?

We are currently located in Wuxi, Jiangsu Province, China. You can come and arrive at Wuxi Sunan International Airport and we will pick you up there. It takes only 10 mins to drive from our company to the airport.

Q2. Are you producing machine’s specific parameters on the basis of the samples?

A: Yes, we will try to produce the machine you want according to your samples or technical drawings.

Q3. What is the Minimum Order Quantity of your machine?

A: Normally our MOQ is 1 set.

Q4. What is your advantage?

A: We keep good quality and competitive price of our products to ensure our customers’ benefit; we treat every one of our customers as a friend and we sincerely cooperate with them no matter where they come from.

| model | CBH-550 | CBH-640 | CBH-750 | CBH-960 | CBH-1070 | CBH-1280 | CBH-1412 | CBH-1630 | CBH-2200 |

| mould size | 580×580 | 680×480 | 780×580 | 980×680 | 1080×780 | 1280×880 | 1400×1200 | 1700×1300 | 2200×1400 |

| core size | 500×500 | 600×400 | 700×500 | 900×600 | 1000×700 | 1200×800 | 1200×1000 | 1600×1200 | 2000×1200 |

| core weight (kg) | 12-40 | 13-50 | 20-60 | 30-80 | 40-100 | 50-120 | 60-220 | 80-250 | 100-350 |

| minimum sand core thickness (mm) | 300 | 300 | 400 | 400 | 500 | 500 | 500 | 600 | 750 |

| maximum mould open distance (mm) | 300 | 300 | 400 | 400 | 500 | 500 | 500 | 500 | 500 |

| operation | manual/automatic for single cycle/completely automatic | ||||||||

| collection | with trolley | ||||||||

| drive | pneumatic | pneumatic/hydraulic | pneumatic/hydraulic | pneumatic/hydraulic | pneumatic/hydraulic | pneumatic/hydraulic | pneumatic/hydraulic | pneumatic/hydraulic | pneumatic/hydraulic |

| pneumatic entrance pressure (mpa) | 0.5-0.7 | ||||||||

| pneumatic entrance size | DN40 | DN50 | |||||||

| shooting direction | from the top | ||||||||

| shooting pressure (mpa) | 0.2-0.55 | ||||||||

| cycle time (s) | 20 | 28 | 32 | 39 | 50 | 58 | |||

| machine weight (kg) | 4000 | 5500 | 7500 | 11500 | 14000 | 165000 | 18000 | 21000 | 26000 |