- Product Details

- {{item.text}}

Quick Details

-

Design Style:

-

Modern

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

B05 aac panel

-

Model Number:

-

Dongyue aac panel

-

color:

-

weight

-

Weight:

-

520kg/m3

-

average compressive strength:

-

3.5-5N/mm2

-

method:

-

aerated autoclaved

-

sound reduction:

-

30-60Db

-

thermal conductivity:

-

0.1322/(m.k)

-

fireproof:

-

last 4 hours

-

Drying shrinkage value:

-

0.48mm/m

-

Certificate:

-

ISO9001:2008/BV

Quick Details

-

Type:

-

ALC

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation, Others

-

Application:

-

Apartment

-

Design Style:

-

Modern

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

B05 aac panel

-

Model Number:

-

Dongyue aac panel

-

color:

-

weight

-

Weight:

-

520kg/m3

-

average compressive strength:

-

3.5-5N/mm2

-

method:

-

aerated autoclaved

-

sound reduction:

-

30-60Db

-

thermal conductivity:

-

0.1322/(m.k)

-

fireproof:

-

last 4 hours

-

Drying shrinkage value:

-

0.48mm/m

-

Certificate:

-

ISO9001:2008/BV

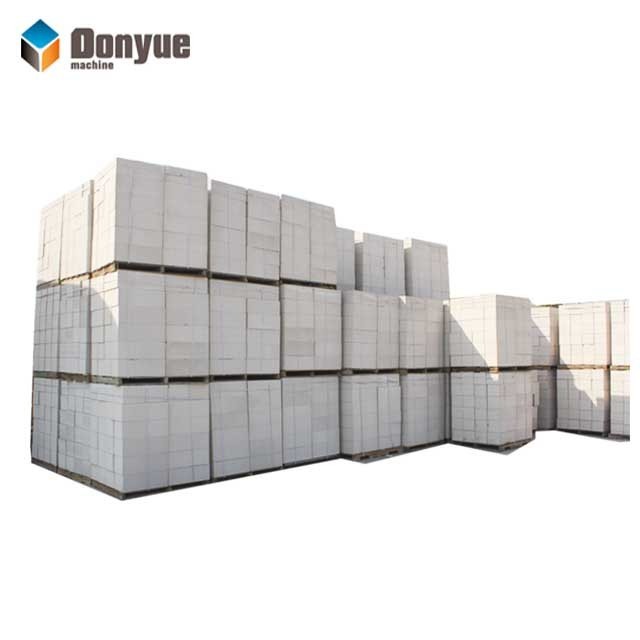

Lightweight AAC Blocks AAC Panel Prefabricated Interior Wall Panels

Features & Advantages of lightweight aac wall floor panel

1. Lightweight : Aerated concrete density is usually 400-900 kg/m3(according to the market),

which is 1/3 of clay block and 1/5 of common concrete.

2.Fireproof : Most of the major raw materials is inorganic materials, so it has good fire resistance,

and do not emit harmful gases when meet fire

3.Sound insulation: As the material inside has a large numbers of the pores and porous, which

has a good thermal insulation properties.

4.Thermal Insulation : Thermal conductivity is 0.9-0.22 W/(MK), which is 1/4 of clay bricks.

5.Anti-seismic: It can improve the two seismic than the brick level.

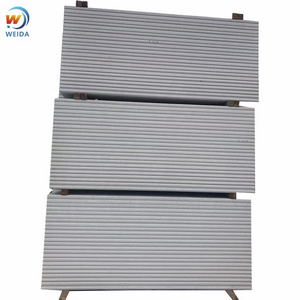

Standard Size

|

Product Name |

Height/Length (mm) |

Width/Height (mm) |

Thickness (mm) |

| AAC External Panel | ≤3600 | 600 | 100 |

| AAC Extenral Panel | ≤4200 | 600 | 120 |

| AAC External Panel | ≤5200 | 600 | 150 |

| AAC External Panel | ≤6000 | 600 | 175 |

| AAC Extenral Panel | ≤6000 | 600 | 200 |

|

AAC Internal Panel |

≤3000 |

600 |

75 |

| AAC Internal Panel | ≤4000 | 600 | 100 |

| AAC Internal Panel | ≤5000 | 600 | 120 |

| AAC Internal Panel | ≤6000 | 600 | 150 |

| AAC Internal Panel | ≤6000 | 600 | 175 |

| AAC Internal Panel | ≤6000 | 600 |

200 |

| AAC Floor Slab |

≤1800 |

600 | 75 |

| AAC Floor Slab | ≤2100 | 600 | 100 |

| AAC Floor Slab | ≤2400 | 600 | 120 |

| AAC Floor Slab | ≤3400 | 600 | 150 |

| AAC Floor Slab | ≤4500 | 600 | 200 |

| AAC Floor Slab | ≤5700 | 600 | 250 |

| AAC Floor Slab | ≤6000 | 600 | 300 |

| AAC Roof Slab | ≤2700 | 600 | 100 |

| AAC Roof Slab | ≤3500 | 600 | 120 |

| AAC Roof Slab | ≤4000 | 600 | 150 |

| AAC Roof Slab | ≤6000 | 600 | 200 |

| AAC Roof Slab | ≤6000 | 600 | 250 |

| AAC Roof Slab | ≤6000 | 600 | 300 |

Special size

|

Product Name |

Height/Length (mm) |

Width/Height (mm) |

Thickness (mm) |

| AAC Special Panel 1 | ≤2400 | 600 | 50 |

| AAC Special Panel 2 | ≤3000 | 600 |

75 |

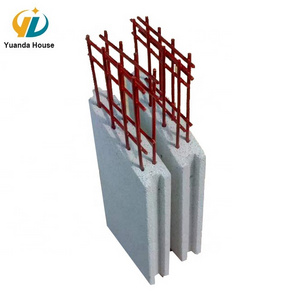

5 workers form a group. Use hydraulic trolley for transportation. Panels should be kept flat during the transportation. Pulling on the floor or unilateral support is forbidden during transportation. Use special fixture when lifting. Hoisting belt should be flexible nylon tie belt.

Use 1:3 cement mortar on the bottom of the panel to make level, mortar thickness is 10-20mm.

While installation, one worker uses a chain hoist to make the panel stand up, other workers stabilize the panel to the corresponding location.

Each panel should be connected to major structure by a special U-Card which is shot on the panels by nail gun.

After panel is upright, adjust the verticality by a wadge stuffed on the bottom of the panel.

Groove between panels to bite each other should be close. Pay attention to control the verticality during the installation, and check up carefully after installation.

Gap between panels to be caulked by special mortar, and extra mortar should be pushed out while connecting panels. Then clean up adhesive cracks between panels, and use specialized pointing mortar to fill up gaps and level out.

To avoid cracking on gaps between panels, cover the adhesive gap with a layer of 200mm wide alkali-resistance fibre mesh.

Dongyue Machinery Group Co.,Ltd

Add:Dongyue Industry Area,Yinan County,Linyi city,Shandong Province,China

Harold Song Sales Manager

Email: harold at donyuegroup.com

Skype: harold1988610

Mobile No./Viber/WhatsApp:+86 18264925825