- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

QINGDAO HUAXIN

-

Voltage:

-

380V

-

Power:

-

2.6KW

-

Dimension(L*W*H):

-

1241X554X1010MM

-

Applicable Industries:

-

FOUNDRY PLANT

-

Name:

-

200kg foundry ladle

-

Material:

-

Steel

-

Color:

-

Original Color

-

Keyword:

-

Hot Metal Ladle

-

Certification:

-

ISO9001 CE, CE AND ISO9001

-

Service:

-

Customized OEM

-

Dimensions:

-

Customers' Orders

-

Lead Time:

-

15-35 Days

-

Process:

-

Casting machine

-

Quality Control:

-

100% Inspection

-

Weight:

-

110KGS

Quick Details

-

Place of Origin:

-

Shandong, China

-

Machine Type:

-

200kg foundry ladle

-

Marketing Type:

-

Hot Product 2020

-

Brand Name:

-

QINGDAO HUAXIN

-

Voltage:

-

380V

-

Power:

-

2.6KW

-

Dimension(L*W*H):

-

1241X554X1010MM

-

Applicable Industries:

-

FOUNDRY PLANT

-

Name:

-

200kg foundry ladle

-

Material:

-

Steel

-

Color:

-

Original Color

-

Keyword:

-

Hot Metal Ladle

-

Certification:

-

ISO9001 CE, CE AND ISO9001

-

Service:

-

Customized OEM

-

Dimensions:

-

Customers' Orders

-

Lead Time:

-

15-35 Days

-

Process:

-

Casting machine

-

Quality Control:

-

100% Inspection

-

Weight:

-

110KGS

Product Description

Casting ladle for foundry plant includes hot metal ladle, molten steel ladle, spheroidizing ladle, aluminum ladle, teapot ladle, copper ladle and soon on .

Casting ladle and customized special casting ladle, as well as lifting ring roller table and lifting ladle. In addition, we also

want to match the baking ladle, electric furnace dust collector, electric furnace charging equipment, etc.

Casting ladle and customized special casting ladle, as well as lifting ring roller table and lifting ladle. In addition, we also

want to match the baking ladle, electric furnace dust collector, electric furnace charging equipment, etc.

Ladle Foundry

Foundry Ladle For Iron Casting

Foundry Ladle For Iron Casting / 200kg foundry ladle

Foundry Ladle For Iron Casting / 500kg foundry ladle

Foundry Ladle For Iron Casting / 750kg foundry ladle

Foundry Ladle For Iron Casting / 1000kg foundry ladle

Foundry Ladle For Iron Casting / 1500kg foundry ladle

Foundry Ladle For Iron Casting / 2000kg foundry ladle

I. Purpose

Molten iron ladle is used for casting operation in the casting workshop. After receiving molten iron in front of the furnace, a traveling crane is transported to the casting mold for casting.

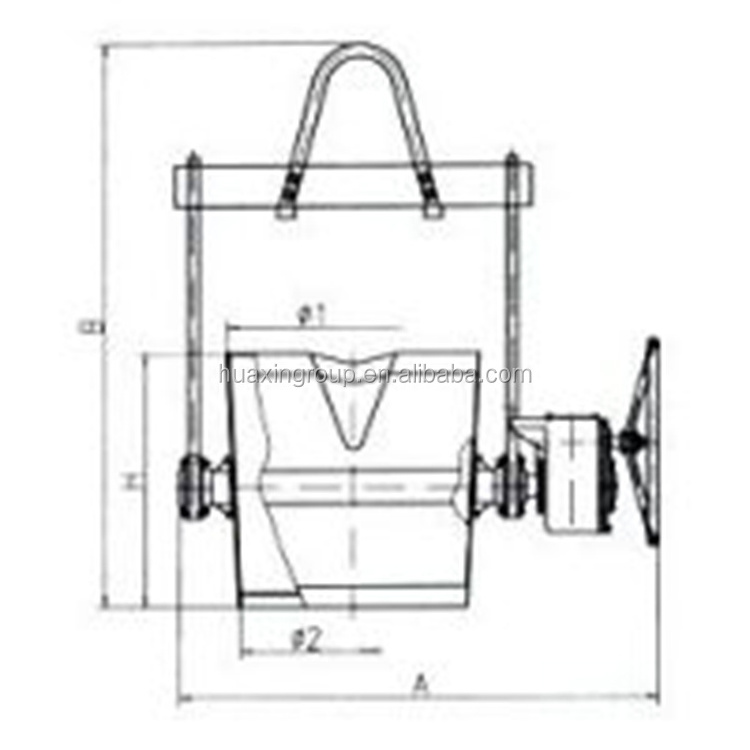

II. Main Technical Parameters and Overall Dimensions

1, hanging bag form, two-way rotary type

2, reducer form, double worm gear pair transmission

3. Speed ratio (as shown in the chart)

4. Overall dimensions (such as chart)

III. Features

1. The rotary center is reasonably selected, which is convenient to operate and can be basically re-made after pouring is completed.

2. Double worm gear pair is adopted for transmission. Although the manufacturing requirements are high, the transmission is flexible and has good bidirectional reversibility.

3. The hanger rod is forged, which is more reliable than steel plate welded parts.

4. The steel plate of the bag body is relatively thick, and the structure of the bag bottom adopts triple insurance combining taper, bottom hoop and welding, thus prolonging the service life and ensuring the safety of the operator.

5, the main body and boom, reducer and handwheel, are equipped with chain card plate can be locked at any time.

6. The two trunnions and the hanger rod are equipped with self-aligning bearings with good consistency.

IV. Use and Maintenance

1, lining refractory mud, its thickness is:

0.5t ~ 3t sidewall 60mm bottom 80mm

5 ton sidewall 80 mm bottom 100 mm

10t sidewall 100mm bottom 120mm

More than 10 tons of sidewall > 150 mm bottom > 180 mm.

2, check the handwheel, should live freely, no jam phenomenon

3, two trunnion rolling bearing, add molybdenum disulfide grease once a week

4, check whether the handwheel lock card is reliable

5, check whether the reducer is short of oil, check once a week

6. If the clearance of worm gear pair is found to hinder pouring after long service life, the worm gear pair should be replaced, and contact can be made directly by letter. The company can provide spare parts.

Qingdao manufacturers customize various models of 0.5-15 ton hot metal ladle for metal casting industry

Specification

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Recommend Products

PROFESSIONAL CASTING MACHINERY FOR FOUNDRY PLANT

There are so many kinds of casting machinery for sand casting technology , sand prepatation, sand molding machine , core shooter machine , shot blasting machine , furnace , foundry ladle, sand treatment line and automatic static pressure molding line and soon on.

Company Introduction

Since its founding in 1998 as Qingdao Huaxin Group, the mission of qingdao huaxin group has been to develop the most innovative solutions possible for the automation of green sand moulding, sand core making machine, sand preparation and shot blasting processes throughout the foundry industry. Continuous technological improvement and innovation have earned nearly 20 intellectual property rights in China. Today, with nearly 5,000 sand moulding machines and shot blasting systems installed around the world, and its sales and service operations are spread all over the world.

FAQ

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Certifications

Customer Photos

Hot Searches