- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

0.2~0.4%

-

CrO Content (%):

-

0.1~0.3%

-

SiC Content (%):

-

0.1~1.4%

-

Place of Origin:

-

Shandong, China, Shandong, China

-

Model Number:

-

GL

-

Brand Name:

-

LUYANG

-

Product name:

-

High alumina corrosion resistant refractory brick firebrick

-

Color:

-

White or yellow

-

Size:

-

Can be customized as your drawing or request

-

Package:

-

export wooden pallet or box

-

OEM service:

-

Accepted

-

Application:

-

Industrial Furnaces

-

Certificate:

-

ISO9001

-

Refractoriness:

-

≥1700℃

Quick Details

-

SiO2 Content (%):

-

1.0%

-

Al2O3 Content (%):

-

≥55%

-

MgO Content (%):

-

0.05%

-

CaO Content (%):

-

0.2~0.4%

-

CrO Content (%):

-

0.1~0.3%

-

SiC Content (%):

-

0.1~1.4%

-

Place of Origin:

-

Shandong, China, Shandong, China

-

Model Number:

-

GL

-

Brand Name:

-

LUYANG

-

Product name:

-

High alumina corrosion resistant refractory brick firebrick

-

Color:

-

White or yellow

-

Size:

-

Can be customized as your drawing or request

-

Package:

-

export wooden pallet or box

-

OEM service:

-

Accepted

-

Application:

-

Industrial Furnaces

-

Certificate:

-

ISO9001

-

Refractoriness:

-

≥1700℃

Product Description

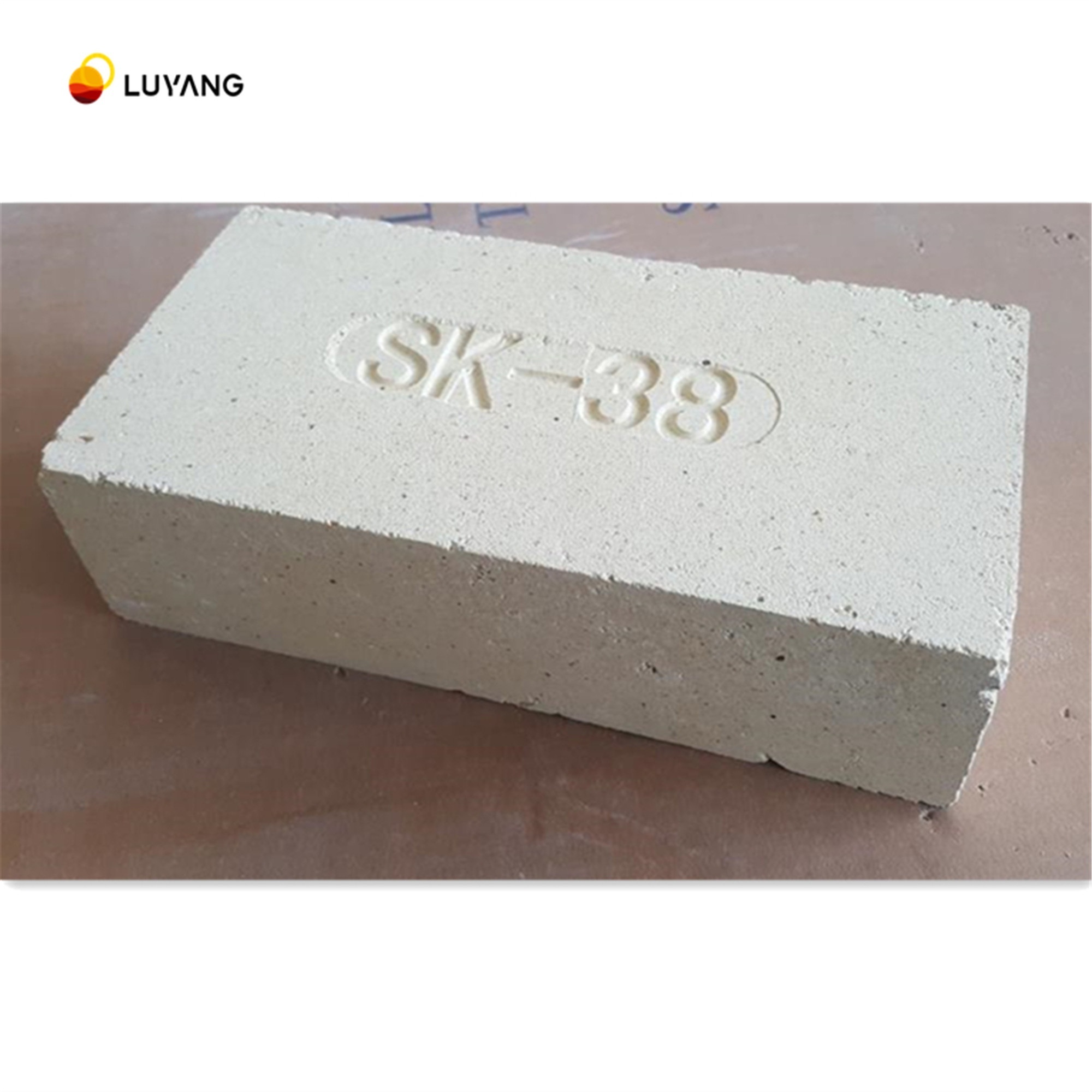

High alumina refractory firebrick

High alumina bricks are produced with selected bauxite chamotte by advanced process and strict quality control. The main mineral components are corundum and mullite phases. Its features are excellent high temperature mechanics and chemical corrosion resistance.

|

Product Name

|

High alumina corrosion resistant refractory brick firebrick

|

|

Common Size

|

230*114*65 230*114*75 230*114*32

230*56*65 230*114*65/45 230*114*65/55 |

|

Other Size

|

Can be customized as your drawing or request

|

|

Refractoriness

|

≥1700℃

|

|

Refractory Type

|

fused cast azs brick, sintered azs brick, zirconia mullite brick, mullite brick,

sillimanite brick, magnesia brick, silica brick, high alumina brick, clay brick, various of insulation brick etc. |

|

Application

|

glass furnace, sodium silicate furnace, frit furnace, metallurgical furnace, ceramic shuttle kiln, cement rotary kiln, tunnel kiln, pizza oven etc.

|

|

Delivery

|

most in stocks with common size, customized brick is 20~60days as your quantity.

|

|

Packages

|

export wooden pallet or box.

|

|

Our Advantage

|

We have professional furnace engineer, we can help u choose suitable brick for your furnace, and also provide the professional technical guide. As the furnace using life is relate with the designing and brick’s quality, If you choose us, we could help your factory create more wealth, and save more cost and time.

|

Specification

|

Item/Grade

|

|

High alumina brick

|

|

|

|

||||

|

|

SK-35

|

SK-36

|

SK-37

|

SK-38

|

SK-40

|

||||

|

AL2O3% (≥)

|

45

|

55

|

65

|

70

|

82

|

||||

|

Fe2O3% (≤)

|

2

|

2

|

2

|

2

|

2

|

||||

|

Refractoriness(SK)

|

35

|

36

|

37

|

38

|

40

|

||||

|

Refractoriness under load, 0.2MPa, °C (≥)

|

1420

|

1450

|

1480

|

1530

|

1600

|

||||

|

Apparent porosity (%)

|

18-20

|

20-23

|

20-23

|

20-22

|

18-20

|

||||

|

Bulk density (g/cm³)

|

2.15-2.22

|

2.25-2.4

|

2.3-2.5

|

2.4-2.6

|

2.5-2.7

|

||||

|

Cold crushing strength ,MPa (≥)

|

40

|

45

|

50

|

60

|

70

|

||||

Features

Mechanical strength

Excellent load-bearing properties

High temperature

Excellent resistance to spalling

Resistant to corrosion

Suitable For

Cement Rotary Kilns

Laddle Lining

Glass industries

Blast furnaces Stoves & Checkers

Electric Furnace Roof

Mechanical strength

Excellent load-bearing properties

High temperature

Excellent resistance to spalling

Resistant to corrosion

Suitable For

Cement Rotary Kilns

Laddle Lining

Glass industries

Blast furnaces Stoves & Checkers

Electric Furnace Roof

Our service

Our Service

1. Strict QC & Fast delivery.

2. Free samples are available by freight collect.

3. High quality goods, Perfect Pre-sales, and good designing service.

4. Welcome to visit our factory at anytime on site or online .

5. We will update you the production process after placing order by photos or online.

6. We have special after-sales team to solve your problem during using our products.

3. High quality goods, Perfect Pre-sales, and good designing service.

4. Welcome to visit our factory at anytime on site or online .

5. We will update you the production process after placing order by photos or online.

6. We have special after-sales team to solve your problem during using our products.

Hot Searches