- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Darsen

-

Model Number:

-

DS-306

-

Product name:

-

Ink decolorization test machine

-

Display:

-

LCD Screen Display

-

Friction Speed:

-

43~150times/min ( 21,43,85,106 times/min, adjustable)

-

Friction Area:

-

155(L)mm*50(w)mm

-

Friction Stroke:

-

Friction Stroke

-

Friction Times:

-

0~999999 Times

-

Friction Load:

-

2lb, 4lb

-

Specimen Size:

-

220(L)mm*50(B)mm

-

Power Supply:

-

220V 50Hz

-

Working Temperature:

-

15℃-35℃

Quick Details

-

Warranty:

-

1 Year

-

Power:

-

Electronic

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Darsen

-

Model Number:

-

DS-306

-

Product name:

-

Ink decolorization test machine

-

Display:

-

LCD Screen Display

-

Friction Speed:

-

43~150times/min ( 21,43,85,106 times/min, adjustable)

-

Friction Area:

-

155(L)mm*50(w)mm

-

Friction Stroke:

-

Friction Stroke

-

Friction Times:

-

0~999999 Times

-

Friction Load:

-

2lb, 4lb

-

Specimen Size:

-

220(L)mm*50(B)mm

-

Power Supply:

-

220V 50Hz

-

Working Temperature:

-

15℃-35℃

Summary :

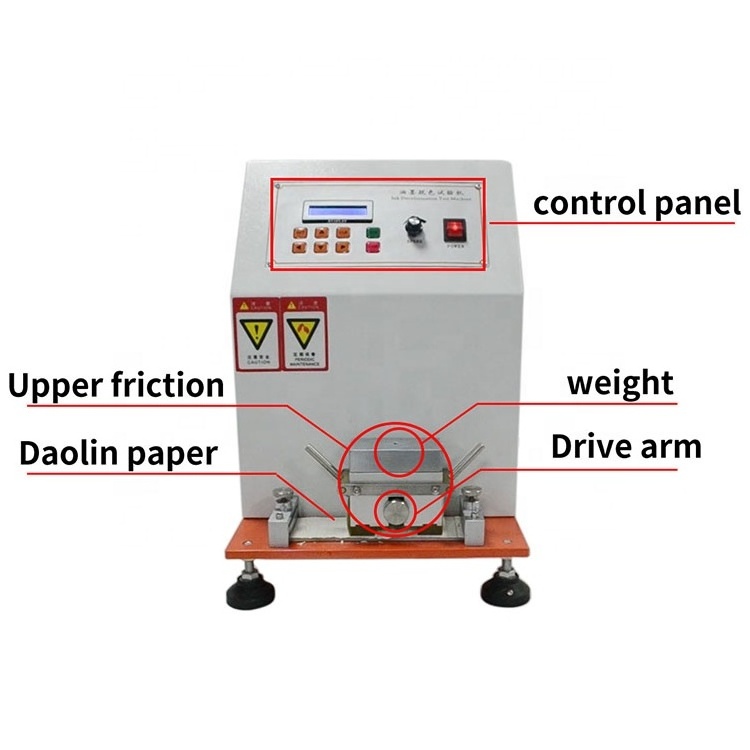

The ink decolorization tester is mainly used to test the wear resistance of printing ink layer of printed matter, the wear resistance of photosensitive layer of PS plate, the wear resistance of surface coating of related products, and the wear performance and decolorization rate of printing box. Effectively analyze the problems such as poor scratch resistance of printed matter, falling off of ink layer, low printing resistance of PS plate and poor coating hardness of other products.

Test Standards :

ASTM D5264 | TAPPI T830 | JIS K5701 | GB/T7706 | GB7707 and so on.

Test theory:

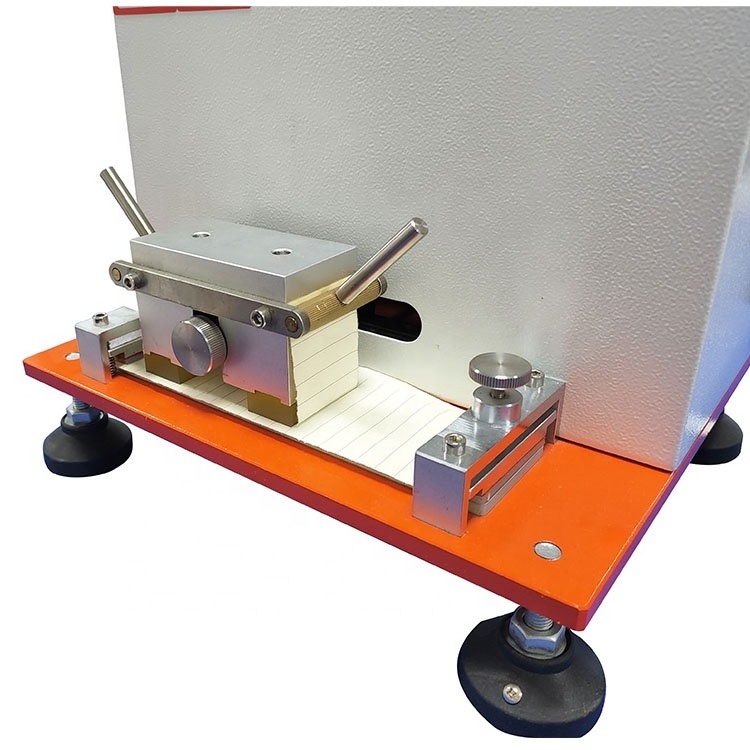

The test specimen mounted on top of the rubber pad is rubbed against the receptor mounted to the weight. The test

duration is determined by the number of strokes. The number of strokes desired is preset on the timer and the tester will

shut off automatically when the desired number of strokes is completed.

Main Feature s:

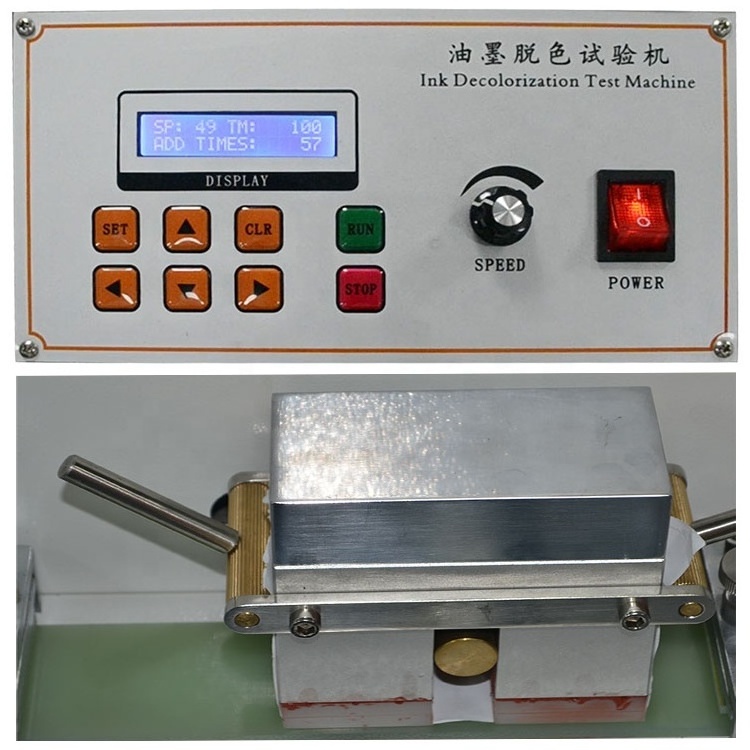

• LCD displays data, convenient and effective.

• Film keyboard switch; PVC operation panel;

• Power failure memory;

• Built-in standard rub panel

• Mute-sounds design, even friction.

Technical Specifications:

|

TECHNICAL SPECIFICATIONS |

|

|

Display |

LCD Screen Display |

|

Friction Speed |

43 times/min ( 21,43,85,106 times/min, adjustable) |

|

Friction Area |

155(L)mm * 50( W )mm |

|

Friction Stroke |

60mm |

|

Friction Times |

0~999999 Times |

|

Friction Load |

2lb, 4lb |

|

Specimen Size |

220(L)mm * 50(B)mm |

|

Power Supply |

220V 50Hz |

|

ENVIRONMENT REQUIREMENT |

|

|

Working Temperature |

RT~4 5℃ |

|

Relative Humidity |

No more than 70%,no dewdrop |

|

Configurations |

|

|

Ink printing Sutherland Rub Tester Host, standard friction block |

|

We have professional packing team and shipping forwarder to pack and deliver your products!

Packing:

1. Out packing:Standard export wooden case.

2. Inner packing:With careful stretch film wrap product, hard wood board+ strong bandage to fix corners.

3. Checking teams: Specialized staff to inspect and classified your goods.

Shipping:

You can specify other shipping methods such as Airmail, FEDEX or DHL. We shall let you know about the shipping cost after receipt ofyour order. It's more preferable for you to provide us with your own FEDEX/DHL account number so that the delivery charge can be charged directly from your account.

During the whole business process, we offer Consultative Selling service.

1)Customer inquiry process:

Discussing testing requirements and technic details, suggested suitable products to customer to confirm. Then quote most suitable price according to customer requirements.

2)Specifications customize process:

Drawing related drawings to confirm with customer for customized requirements. Offer reference photoes to show the proucts appearance. Then, confirm the final solution and confirm final price with customer.

3)Order process: We offer below business term:

|

Accepted Delivery Terms |

FOB, CFR, CIF, EXW, DDP |

|

Accepted Payment Currency |

USD, EUR, HKD, CNY |

|

Accepted Payment Type |

T/T, L/C, Credit Card, PayPal, Western Union, Cash, Escrow |

|

Nearest Port |

Shenzhen, Guangzhou, Shanghai, Qingdao, Tianjing or rquired |

4)Production and delivery process:

We will produce the machines according to confirmed PO requirements. Offering photoes to show production process.

After finish production, offer photoes to customer to confirm again with the machine. Then do own factory calibration or third party calibration(as customer requirements). Check and test all the details and then arrange packing. Deliver the products in confirmed shipping time and inform customer.

5)Installation and after sale service:

Defines installing those products in the field and providing after-sales support.