- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

According to different model

-

Weight:

-

KG

-

Product name:

-

Direct discharge vibrating screen

-

Material:

-

Stainless Steel

-

Mesh size:

-

600-1500 Mesh

-

Layer(s):

-

1-5 Layers

-

Diameter:

-

550-1400mm

-

Keyword:

-

Vibratory Screen

-

Feature:

-

High Efficiency

-

Usage:

-

Filtration

-

Advantage:

-

Professional

-

After-sales Service Provided:

-

Online support

Quick Details

-

Type:

-

Circular

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

sanyuantang

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

According to different model

-

Weight:

-

KG

-

Product name:

-

Direct discharge vibrating screen

-

Material:

-

Stainless Steel

-

Mesh size:

-

600-1500 Mesh

-

Layer(s):

-

1-5 Layers

-

Diameter:

-

550-1400mm

-

Keyword:

-

Vibratory Screen

-

Feature:

-

High Efficiency

-

Usage:

-

Filtration

-

Advantage:

-

Professional

-

After-sales Service Provided:

-

Online support

Product description

Direct Discharging Vibrating Screen

Direct discharging vibrating screen is divided into two kinds of single vibration source and double vibration source, with large flow outlet at the bottom, inlet and outlet designed in the same vertical direction, the finished products under the screen quickly pass through the mesh, reduce the time of the material staying on the screen surface, rapid discharging, large capacity, easy to combine with the production line. Mainly used in powder production line process of the powder in addition to impurity, sieving and so on.

Application

Flour, starch, laundry detergent, metal powder, additives, chemical industry, non-mineral and other industries of the particles of powder rough screening, precision screening.

Features

1.High efficiency,compact design and durability, any powder and liquid can be sieved

2.Easy to replace screen, operation simple, easy to clean

3.Mesh is not blocked,the powder is not flying, impurities and coarse material discharged automatically, can work continuously

4.With vertical vibration motor, no mechanical transmission, transfer process without loss.

5.Unique grid design, screen can last a long time

6.Small size, does not occupy space, easy to move

7.All stainless steel for creen section

2.Easy to replace screen, operation simple, easy to clean

3.Mesh is not blocked,the powder is not flying, impurities and coarse material discharged automatically, can work continuously

4.With vertical vibration motor, no mechanical transmission, transfer process without loss.

5.Unique grid design, screen can last a long time

6.Small size, does not occupy space, easy to move

7.All stainless steel for creen section

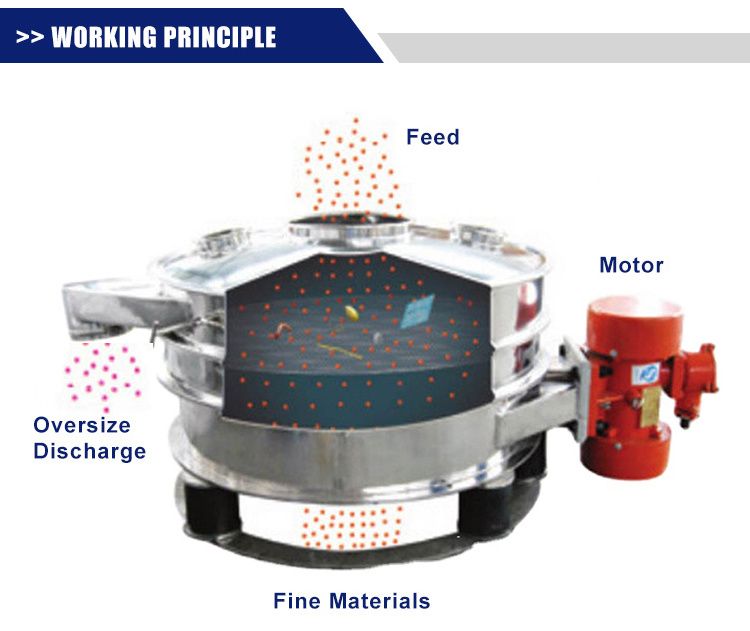

Working Principle

The Direct discharging vibrating screen uses the vibrating motor to utilize the phase angle of the two sets of eccentric blocks (unbalanced eccentric blocks) at the upper and lower ends of its shaft as well as the cross angle between the two motors to change the rotary motion of the vibrating motor into the overlapping of horizontal, vertical, inclined and centrifugal multi-functional force, and then transfer this force to the sieve surface, so as to achieve the purpose of sieving. Changing the phase angle and weight of the upper and lower eccentric blocks can change the size of the excitation force and the trajectory of the material.

Product Parameters

|

product name

|

Small vibrating screen

|

|

device height

|

850mm

|

|

Screen diameter

|

500mm

|

|

Screen frame height

|

150mm

|

|

Hopper material

|

304 stainless steel

|

|

weight

|

17kg

|

|

Screen layers

|

single layer

|

|

Small mouth diameter

|

89mm

|

|

The height of the outlet from the ground

|

380mm

|

|

Material running track

|

vibration

|

|

Motor Power

|

50w 70w

|

|

Motor voltage

|

Motor voltage

|

|

Suitable

|

Flour, Chinese medicine, tea, aluminum, zinc,

plastic powder, etc.

|

Why Choose Sanyuantang

1) International high quality certification product chain

2) Manufacturer, more reasonable price

3) Solid technical support and after-sales service

4) Uphold the principle of "Customer Supreme"

5) Exports to more than 20 countries and regions, good customers feedback

6) One-stop service, customized exclusive project feasibility report.

1) International high quality certification product chain

2) Manufacturer, more reasonable price

3) Solid technical support and after-sales service

4) Uphold the principle of "Customer Supreme"

5) Exports to more than 20 countries and regions, good customers feedback

6) One-stop service, customized exclusive project feasibility report.

FAQ

Q: What are you mainly specilized in?

A: Our company is a professional manufacture of vibrating screen sifter equipments(like rotary vibrating

screen,ultrasonic sieving machine,linear vibrating screen,test sieve machine,trumbler screem,drum screen,

direct discharge screen,airflow sieving machine,450 filter machine and so on);conveying equipment (like

screw conveyor,bucket elevator,vertical vibration elevator and so on);honey machine(honey processing

machine,honey filling machine)

Q:What's your after-sales services?

A: 24 hours service online,you can tell your trouble any time.

Q:What is the MOQ of our products?

A:Usually 1 set.

Q:What is the payment terms?

A. Usually use T/T,but Western Union is also available.

Q:What's your delivery time?

A:Ususlly 7-10 working days,if the order is large,the time should be longer.

Q:What's the advantage compared to other suppliers?

A:We are a factory,We have business directly with our customers,there isn't any link between customers,so we can offer competitive

price for you.

A: Our company is a professional manufacture of vibrating screen sifter equipments(like rotary vibrating

screen,ultrasonic sieving machine,linear vibrating screen,test sieve machine,trumbler screem,drum screen,

direct discharge screen,airflow sieving machine,450 filter machine and so on);conveying equipment (like

screw conveyor,bucket elevator,vertical vibration elevator and so on);honey machine(honey processing

machine,honey filling machine)

Q:What's your after-sales services?

A: 24 hours service online,you can tell your trouble any time.

Q:What is the MOQ of our products?

A:Usually 1 set.

Q:What is the payment terms?

A. Usually use T/T,but Western Union is also available.

Q:What's your delivery time?

A:Ususlly 7-10 working days,if the order is large,the time should be longer.

Q:What's the advantage compared to other suppliers?

A:We are a factory,We have business directly with our customers,there isn't any link between customers,so we can offer competitive

price for you.

Contact us

The proper selection of vibrating screen depends on the material, mesh size, output required, method of input etc:

1. Name of material: _____

2. Moisture:_____%

3. Specific gravity:_____

4. Capacity:________kg/ hour

5. Screen layer:_______

6. Screen mesh size:______ mesh . ______ mesh. ______ mesh

7. Voltage:______V, Frequency:______HZ, ______phase

8. All 304 stainless steel or contact materials part is 304 stainless steel or all carbon steel?

Hot Searches