- Product Details

- {{item.text}}

Quick Details

-

Formaldehyde Emission Standards:

-

E1

-

Place of Origin:

-

South Africa

-

Brand Name:

-

Plywoods

-

Model Number:

-

Plywoods

-

Plywoods:

-

Plywoods

Quick Details

-

Warranty:

-

NONE

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation, NONE

-

Application:

-

Home Office

-

Formaldehyde Emission Standards:

-

E1

-

Place of Origin:

-

South Africa

-

Brand Name:

-

Plywoods

-

Model Number:

-

Plywoods

-

Plywoods:

-

Plywoods

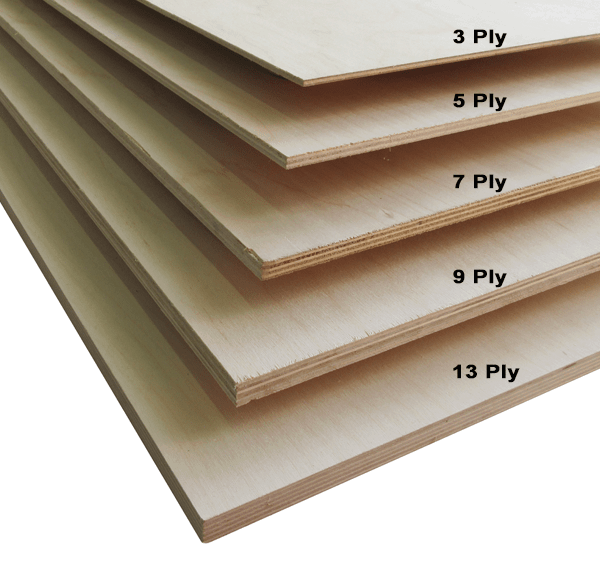

Plywood is one of the commonly used materials for furniture, one of the three major panels of wood-based panels, and can also be used for aircraft, ships, trains, automobiles, buildings and packaging boxes. A set of veneers is usually glued together vertically to each other in the direction of adjacent layers of wood grain, and its surface plate and inner plate are usually symmetrically arranged on both sides of the central layer or core. The slabs made of glued veneer crisscrossed in the direction of the wood grain are pressed under heated or unheated conditions. The number of layers is generally odd, and a few are even.

|

Product Name |

Plywood |

|

Color |

lots of colors:wood grain,solid color,cloth color and stone |

|

Size |

1220x2440mm or customized size |

|

Glue |

E0,E1 |

|

Material |

poplar,eucalyptus,birch etc |

|

Application |

making furniture,closet,kitchen,cabinet |

|

Thickness |

3-25mm |

|

Thickness Tolerance |

0.2-0.5mm |

|

Key word |

melamine plywood |

|

Hotpress |

3 times hotpress |

|

Surface |

high glossy,glossy,Matt, Embossed, Smooth |

|

Extra service |

Customized size ,shape ,edge banding |

|

Item |

Commercial plywood, Packing plywood, Furniture plywood |

|

|

Face/Back |

Okoume, Bintangor, Bleached poplar, Red pencil cedar,Pine, Birch, Maple,

|

|

|

Core |

Poplar, hardwood, combi |

|

|

Grade |

BB/BB, BB/CC, CC/CC, C+/C, C/C, C/D, D/E etc |

|

|

Hot press |

1 time or 2 times |

|

|

Glue |

MR, E2, E1, E0 |

|

|

Size |

1220×2440mm, 1250×2500mm, 915×2135mm, 915*1830mm or as request |

|

|

Thickness |

2 - 25mm |

|

|

Density |

500-600 KGS/CBM |

|

|

Moisture |

To be 6%-14% at time of shipment |

|

|

Thickness tolerance |

Less than 6mm |

+/-0.2mm to 0.3mm |

|

6-25mm |

+/-0.4mm to 0.5mm |

|

|

Packing |

Inner with plastic bag,

|

|

|

Loading quantity |

20’GP |

8 plts / 24M3 |

|

40’HQ |

16 or 18 plts / 54M3 |

|

|

Usage |

Furniture, decoration, package |

|

|

Thickness |

2mm-30mm |

|

Face/back |

red cedar |

|

Core |

Materials Poplar/Pine/Eucalyptus/Birch/Paulownia/Hardwood/Combine |

|

Dimension |

3x6',3x7’ , 3x8’,4x7',4x8',4x9',4x10' 1220x2440mm,1250x2500mm,1220x2500mm,1220x3050mm 710/810/910x2135mm of door skin size |

|

Bonding |

MR/Melamine/WBP |

|

Phenolic(Exterior) |

EO/E1/E2(Interior) |

|

Grade |

B/BB,BB/CC,CC/DD,D/E(For birch plywood) |

|

Moisture |

7-12%(depends on the thickness) |

|

Usage |

Usually used for furniture,cabinets,construction and packing |

|

Production Specifications |

|

|

Name |

Cheap Price 18mm Black Film Faced Plywood For Construction |

|

Size |

1220*2440mm(4'*8'),900*2100mm ,1250*2500mm or upon request |

|

Thickness |

9mm ,12mm ,15mm,18mm ,21mm ,24mm or upon request |

|

Thickness Tolerance |

+/-0.5mm |

|

Face/Back |

black ,brown Red ,yellow Film or Dynea dark brown film, Anti Slip film ,plastic film |

|

Core |

Poplar, Eucalyptus, Combi, Birch or upon request |

|

Glue |

Phenolic ,WBP ,MR |

|

Grade |

One Time Hot press / Two Time hot press / Finger-Joint |

|

Certification |

ISO ,CE,CARB ,FSC |

|

Density |

500-700kg/m3 |

|

Moisture Content |

8%~14% |

|

Water Absorption |

≤10% |

|

|

Inner Packing-Pallet is wrapped with 0.20mm plastic bag

|

|

|

20’GP-8pallets/22cbm,

|

|

MOQ |

1x20’FCL |

|

Payment Terms |

T/T or L/C |

|

Delivery Time |

Within 2-3 weeks upon down payment or upon opening of L/C |

|

|

|

Film faced plywood is also called formwork plywood, shuttering plywoods, concrete form.

Dongstar

Film Faced Plywood is mainly made up of eucalyptus plywood, poplar plywood or eucalyptus and poplar plywood, it is economic and practical for the construction concrete pouring, for it could be the face panel for any formwork system, for example, steel frame formwork system, single side formwork system, timber beam formwork system, steel props formwork system, scaffolding formwork system, etc.