- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Y) (mm):

-

500

-

Dimension(L*W*H):

-

2780*2450*2700mm

-

Weight (T):

-

5 T

-

Positioning Accuracy (mm):

-

0.006

-

Repeatability (X/Y/Z) (mm):

-

0.003

-

Spindle Motor Power(kW):

-

7.5/11

-

Max. Table Load(kg):

-

400 kg

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

lu young

-

Voltage:

-

220V/380V

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Machine Type:

-

Vertical Machine Centers

-

Product name:

-

4-axis Vertical Cnc Machining Center

-

Controlling Mode:

-

Cnc System

-

Product type:

-

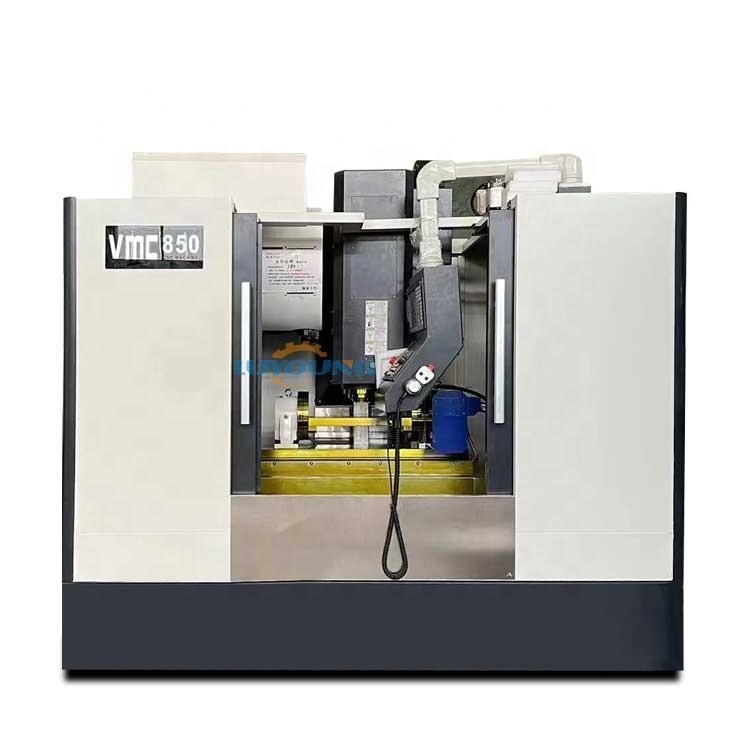

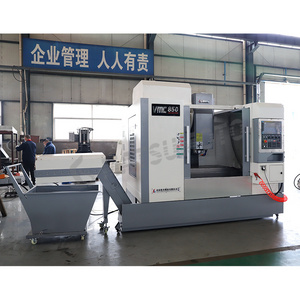

VMC 850 Machining Center

-

Processing:

-

Maching Center

-

Spindle speed:

-

8000 Rpm

-

Application:

-

Metal Machining

-

Control system:

-

SIEMENS GSK FANUC (optional)

-

After Warranty Service:

-

Online support

Quick Details

-

Table Size (mm):

-

1000*500

-

Number of Axes:

-

3, 4, 5

-

Table Travel (X) (mm):

-

800

-

Table Travel (Y) (mm):

-

500

-

Dimension(L*W*H):

-

2780*2450*2700mm

-

Weight (T):

-

5 T

-

Positioning Accuracy (mm):

-

0.006

-

Repeatability (X/Y/Z) (mm):

-

0.003

-

Spindle Motor Power(kW):

-

7.5/11

-

Max. Table Load(kg):

-

400 kg

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

lu young

-

Voltage:

-

220V/380V

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Machine Type:

-

Vertical Machine Centers

-

Product name:

-

4-axis Vertical Cnc Machining Center

-

Controlling Mode:

-

Cnc System

-

Product type:

-

VMC 850 Machining Center

-

Processing:

-

Maching Center

-

Spindle speed:

-

8000 Rpm

-

Application:

-

Metal Machining

-

Control system:

-

SIEMENS GSK FANUC (optional)

-

After Warranty Service:

-

Online support

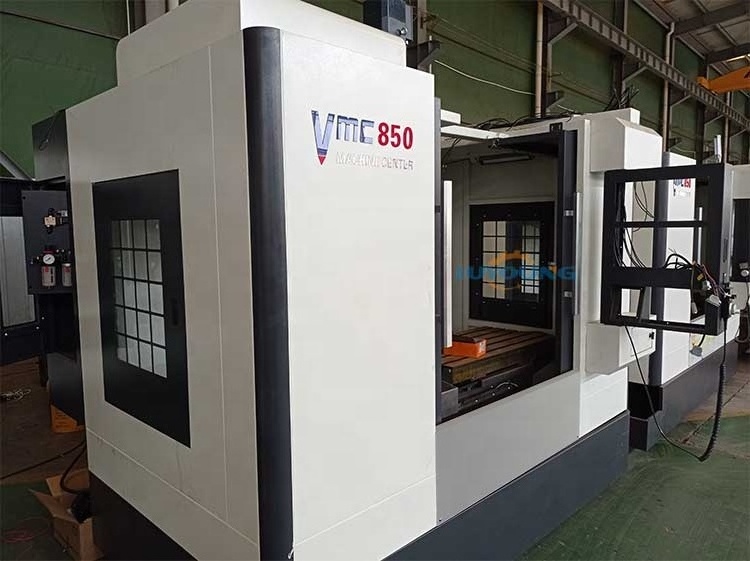

vmc850 vmc855 FANUC system 3-axis 4-axis 5-axis Cnc Machining Center With Automatic Tool Changer For Metal

Specification

|

Item

|

VMC850

|

|

|

Size of worktable(length×width)mm

|

1000×500

|

|

|

T slot (mm)

|

5-18x100

|

|

|

Max loading weight on worktable

|

600kg

|

|

|

X-Axis travel(mm)

|

800

|

|

|

Y-Axis travel(mm)

|

550

|

|

|

Z-Axis travel(mm)

|

500

|

|

|

Distance between spindle nose and table

|

105-605mm

|

|

|

Distance between spindle center and column(mm)

|

550

|

|

|

Spindle taper

|

BT40

|

|

|

Max. spindle speed( rpm)

|

8000/10000/12000

|

|

|

Spindle motor power(Kw)

|

7.5/11kw

|

|

|

Rapid feeding speed: X,Y,Z axis m/min

|

24/24/24 liner guideway

|

|

|

Fast cutting speed m /min

|

10m/min

|

|

|

Positional accuracy

|

±0.005 mm

|

|

|

Repeat positional accuracy

|

±0.003 mm

|

|

|

Auto Tool changer type

|

24 arm type auto tool changer

|

|

|

Max. tool length

|

300mm

|

|

|

Max. Tool diameter

|

Φ80(adjacent tool)/φ150(not adjacent tool)

|

|

|

Max.tool weight

|

8kg

|

|

|

2.5Tool changing time(tool-to-tool)

|

2.5sec

|

|

|

Air pressure

|

0.6 Mpa

|

|

|

Machine weight

|

5500KG

|

|

|

Overall sizse(mm)

|

2600*2300*2300

|

|

|

Standard configuration:

|

|

|

|

High strength resin sand casting

|

Imported bearings for lead -srew; HIWIN/NSK

|

|

|

X, Y, Z rails adopt stainless steel telescopic cover

|

Eelectric cabinet cold heat exchanger

|

|

|

Standard with belt driven Taiwan spindle---8000RPM

|

Full enclosed cover

|

|

|

GSK25I controller system

|

Manual pulse generator (MPG)

|

|

|

16 tools type Taiwan ATC

|

Toolbox

|

|

|

Centralized automatic feed lubrication system

|

3 Axis lubrication oil collection

|

|

|

Air clean gun

|

Color display

|

|

|

Chip storage tank

|

Foundation pad iron and adjusting bolt

|

|

|

Three color warning lamp

|

USB and Internet interface

|

|

|

Cooling system

|

Leveling blocks & bolts;

|

|

|

Work lamp

|

Rigid tapping

|

|

|

Spindle center air blast

|

|

|

|

Optional configuration:

|

|

|

|

Taiwan ATC, disc type ---24

|

4th /5th axis

|

|

|

Siemens or Fanuc controller system

|

Chip conveyor outside machine

|

|

|

3 axis Hiwin linear guide way

|

Tool measure system

|

|

|

Workpiece measure system

|

|

|

|

Main purchase parts brand

|

|

|

|

Name

|

Brand

|

|

|

Spindle Unit

|

Taiwan

|

|

|

Servo Motor

|

SIEMENS/GSK/FANUC

|

|

|

pressure cylinder

|

Taiwan SUNRISE

|

|

|

Screw bearing

|

FAG

|

|

|

Coupling

|

(R+W)

|

|

|

CNC Controller

|

SIEMENS/GSK/FANUC

|

|

Product Description

The

vmc850 vmc855 FANUC system 3-axis 4-axis 5-axis Cnc Machining Center With Automatic Tool Changer For Metal

is suitable for mould, automobile, motorcycle, aviation, aerospace, instrumentation, textile light industry and electronics and machinery manufacturing and other industries, small and medium-sized housing cover, plate, shell and plate parts processing industry.It is applicable to the vertical machining center of machining and mould manufacturing. It can adapt to the machining requirements of machining, drilling, tapping, boring and so on.

Spindle:

Standard is high speed BT40-150

belt driven Taiwan spindle---8000RPM;

Optional is 10000/12000/15000 rpm .

simple and compact structure, high efficiency, low noise, low vibration , high precision,and good surface finishing.

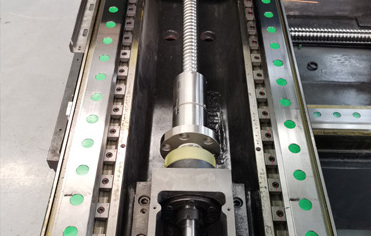

Screw

:

Standard is hardened guide way,optional is Taiwan Hiwin linear guide way.The guide screw adopts the imported JIS-C3 grinding grade pre-stretched nut screw to eliminate the backlash, after heat treatment, it has good rigidity, wear resistance, and guarantees the high precision of the operation.

Auto tool changer:

Taiwan hat type (16 knives) tool magazine. Advantages: low wear, long life, easy adjustment, and low failure rate.Optional configuration is Taiwan 20/24 disc type Auto tool changer.

Controller system

Controller system: there is GSK /KND/SIEMENS/SYNTEC/FANUC controller system could to be choosed

4th and 5th axis :

4th and 5th axis can be choosed as opintional,

Horizontal & vertical cnc rotary table can be choose as optional. Especially for special jobs.

High precision, improve processing efficiency, and shorten the processing flow.

PROBE MEASURING

METROL , RENISHAW or

PIONEER

brand workpiece measuring system and tool measuring system are optional configurations.

Chip conveyor outside machine

The machine tool chip conveyor is mainly used to collect various metal and non-metal scraps produced by the machine and transfer the scraps to the collection vehicle. It can be used in conjunction with the filter water tank to recycle various coolants.

24 tools arm type Auto tool changer

The tool change speed is fast, within 4s. The mechanical arm pulls the tool from the tool magazine and the spindle at the same time and installs it on the spindle and the tool magazine after a 180° rotation to complete the tool change process.

Hot Searches