- Product Details

- {{item.text}}

Quick Details

-

Color:

-

Black, red, blue, as your request

-

Application:

-

Water well, construction, mining

-

Advantage:

-

High Performance

-

Usage:

-

Crusher

-

Carbide Button Shape:

-

Spherical, ballistic, Smei-ballistic, Conical

-

Bit face:

-

Convex face,Flat face,Drop center face

-

Diameter:

-

78mm

-

Other products:

-

DTH hammer, drill rod

Quick Details

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

Propower Drill

-

Product name:

-

Dth diamond drilling bits Reduced maintenance costs bits tools

-

Color:

-

Black, red, blue, as your request

-

Application:

-

Water well, construction, mining

-

Advantage:

-

High Performance

-

Usage:

-

Crusher

-

Carbide Button Shape:

-

Spherical, ballistic, Smei-ballistic, Conical

-

Bit face:

-

Convex face,Flat face,Drop center face

-

Diameter:

-

78mm

-

Other products:

-

DTH hammer, drill rod

Flat/convex/ concave dth diamond drilling bits Reduced maintenance costs drilling bits tools

Name of Product

DTH bit is our main product. After many years search, we have rich experience in development and manufacturing high quality DTH Bits, which adopted high-quality raw materials, advanced technology and passed through strictly inspection.

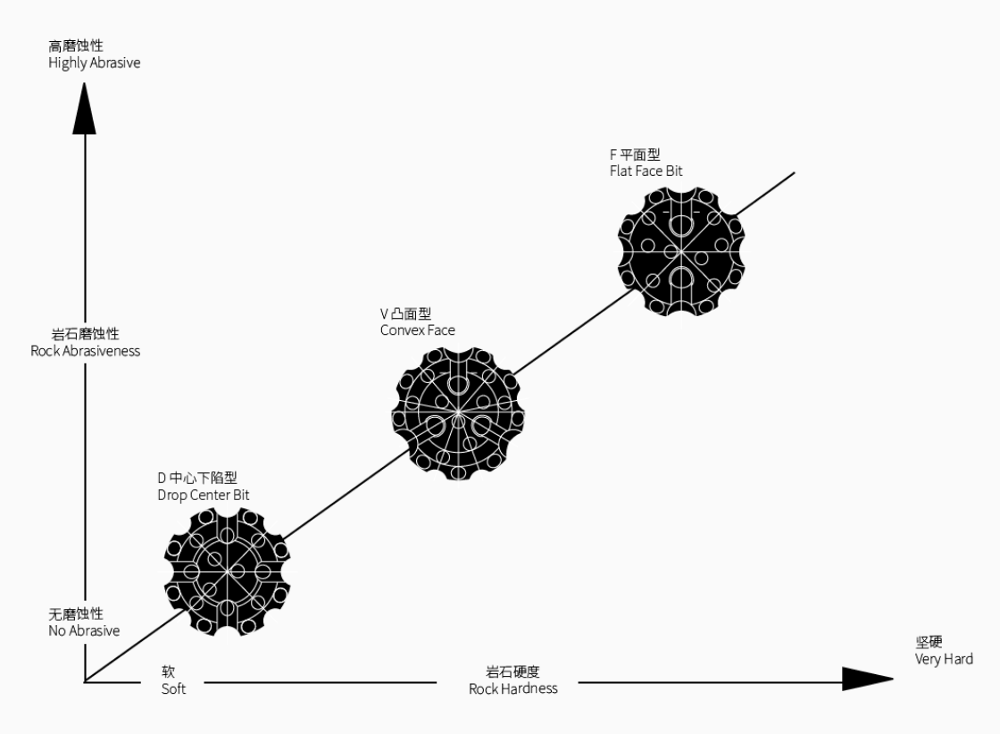

How to Select DTH Bits Face shape and Carbide Button Shape

A:Bits face shape selection

Drop Center Bit

For high penetration rates in soft to medium-hard and fissured rock formations.

Concave Face

The all-round application bit face specifically for medium hard and homogeneous rock formation. Good hole deviation control and good flushing capacity.

Convex Face

For high penetration rates in soft to medium-hard with low to medium air pressure. It is the most resistance to steel wash, and good resistance to steel wash step gauge bit.

Flat Face Bit

This kind of face shape is suitable for hard to very hard and abrasive rock formations in applications with high air pressures. Good penetration rates an resistance to steel wash.

B:Insert Carbide Button shape Selection

Different button is ideal for different ground conditions, abrasive levels, PSIs and penetration levels. In general, the more of gauge buttons, the better over performance, especially in hard rock.

Spherical

> Application Strength-multipurpose

> Best suited to soft abrasive

> 25,000 to 45,000 PSI (170 to 300 MPa)

> Abrasive to very abrasive

Ballistic Button

> Application Strength- fast penetration

> Best suited to soft ground

> 10,000to 20,000 PSI(70 to 140 MPa)

> Non abrasive ground

Semi-ballistic

> Application Strength-fast penetration

> Best suited to medium ground

> 15,000 to 25,000 PSI(100 to 170 MPs)

> Mildly abrasive ground

Wedged (Conical) Button

> Application Strength- fast penetration

> Suited for all non-abrasive ground types

> Smaller contact area

> Best suited for smaller diameter bits