- Product Details

- {{item.text}}

Quick Details

-

Name:

-

Multifunctional extracting Extraction Tank Herbal Extractor

-

Design pressure:

-

0.1Mpa-1Mpa

-

Material:

-

Stainless Steel 304/316L

-

Volume:

-

50~20000L

-

Insulation layer:

-

rockwool/polyurethane

-

Speed:

-

24rpm-2800rpm

-

Heating by:

-

electric/steam/gas

-

Application:

-

dairy, food, beverage, cosmetic, etc

-

Design temperature:

-

customized

Quick Details

-

Model Number:

-

Customization

-

Weight (KG):

-

350

-

Type:

-

Grain Processing Equipment

-

Name:

-

Multifunctional extracting Extraction Tank Herbal Extractor

-

Design pressure:

-

0.1Mpa-1Mpa

-

Material:

-

Stainless Steel 304/316L

-

Volume:

-

50~20000L

-

Insulation layer:

-

rockwool/polyurethane

-

Speed:

-

24rpm-2800rpm

-

Heating by:

-

electric/steam/gas

-

Application:

-

dairy, food, beverage, cosmetic, etc

-

Design temperature:

-

customized

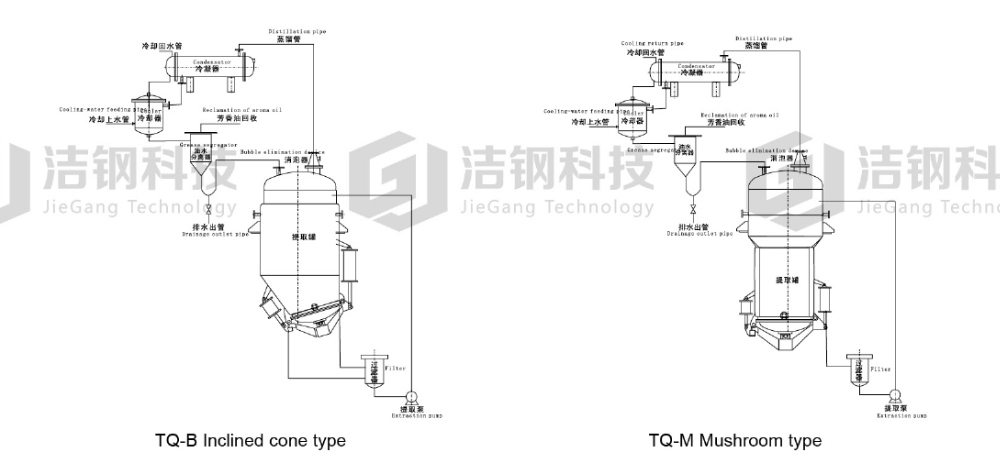

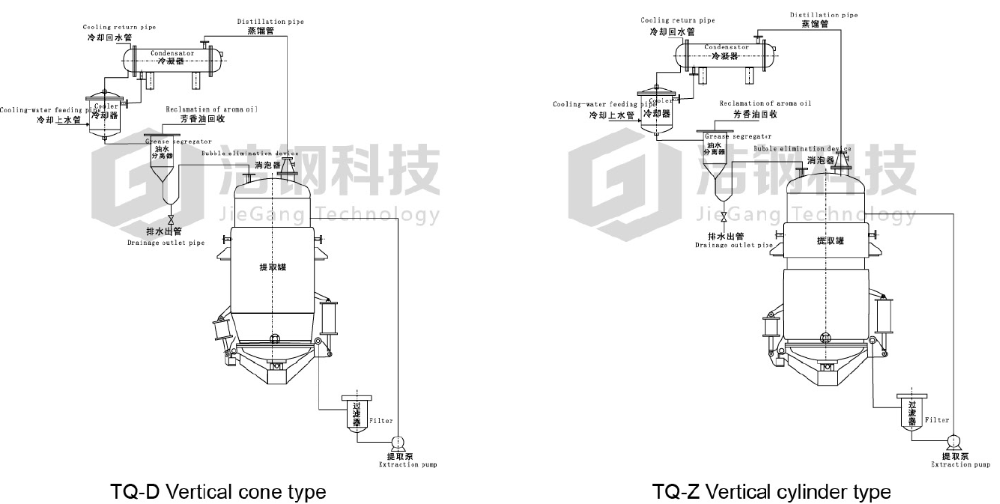

Multifunctional extracting Extraction Tank Herbal Extractor

Technical features:

2. The specially designed back flushing device not only eliminates material accumulation in the extraction tank and enhances leaching rate, but also makes the temperatures at all parts in the tank consistent and ensures the extracting effect.

3. The specially improved side discharging structure not only accelerates the discharging rate, but solves the problem easily blocked during discharging. In addition, it is easy to assemble, disassemble and clean.

5. The new type oil-water separator can collect both light oil and heavy oil. The operation is direct and convenient.

6.The segmented heating mode not only fully meets the requirements of "mild and strong fire" in the extraction process, but effectively ensures the sub-boiling status during the extraction process.

Structure:

The complete equipment supplied shall include: defoamer, condenser, cooler, oil-water separator, filter, cylinder control desk and other accessories.

|

How to choose

|

|

|

|

|

|

|

|

|||||||

|

Specifications

|

1m3

|

2m3

|

3m3

|

6m3

|

7m3

|

8m3

|

10m3

|

|||||||

|

Volume (L)

|

1200

|

2300

|

3200

|

6400

|

7500

|

8600

|

11000

|

|||||||

|

Design pressure in the equipment

|

Pressure

|

|

|

|

|

|

|

|||||||

|

Design pressure in jackte

|

0.3

|

|

|

|

|

|

|

|||||||

|

Pressure of compressed air

|

0.6-0.7

|

|

|

|

|

|

|

|||||||

|

Heating area(m3)

|

3

|

4.2

|

6

|

7.5

|

8.3

|

9.5

|

12

|

|||||||

|

Diameter of material inlet(mm)

|

400

|

400

|

400

|

500

|

500

|

500

|

500

|

|||||||

|

Diameter of slagging door (mm)

|

800

|

800

|

800

|

1000

|

1000

|

1200

|

1200

|

|||||||

|

Blend rotation speed (r/min)

|

23

|

|

|

|

|

|

|

|||||||

|

Motor power(kw)

|

2.2

|

4

|

5.5

|

7.5

|

11

|

11

|

15

|

|||||||

|

Equipment weight(kg)

|

1800

|

2050

|

2400

|

3025

|

3425

|

4030

|

6050

|

|||||||

|

Condensing area

|

6

|

6

|

8

|

12

|

15

|

20

|

25

|

|||||||

|

Cooling area(m2)

|

1

|

1

|

1

|

2

|

2

|

2

|

3

|

|||||||

|

Filtration area(m2)

|

0.25

|

0.25

|

0.3

|

0.65

|

0.65

|

0.65

|

0.65

|

|||||||

Please contact us for more details. Support custom.

How long have you worked in this field?

Over 15 years.

Can your factory supply samples with free if we need?

Yes, we can.

Can your factory produce products according to our drawings or samples?

Yes, of course we can

What is your factory's biggest advantage?

Technology is our core competitiveness.

How about the delivery time ?

Standard products will be 10-15 days after receive your down payment or full payment.

Are you manufacturer or trading company?

We are a professional manufacturer.