- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/220V, 3pha

-

Power:

-

Customized

-

Dimension(L*W*H):

-

Customized Size

-

Weight (KG):

-

2000

-

Workpiece:

-

MDF board

-

Drying & Curing system:

-

Electric;LPG;PETROL all Available

-

Running speed:

-

According to actual output requirement

-

Design feature:

-

Good Quality, Less Mainetance, Affordable price

-

Powder coating booth:

-

Plastic Booth is available

Quick Details

-

Machine Type:

-

MDF powder coating line, Spray Booths, Painting Equipment, Plc Controller Programmable Logic Controller, Pre-treatment Equipment, Conveying Equipment, Drying Oven, Curing oven, Coating Equipment

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Xintu

-

Voltage:

-

380V/220V, 3pha

-

Power:

-

Customized

-

Dimension(L*W*H):

-

Customized Size

-

Weight (KG):

-

2000

-

Workpiece:

-

MDF board

-

Drying & Curing system:

-

Electric;LPG;PETROL all Available

-

Running speed:

-

According to actual output requirement

-

Design feature:

-

Good Quality, Less Mainetance, Affordable price

-

Powder coating booth:

-

Plastic Booth is available

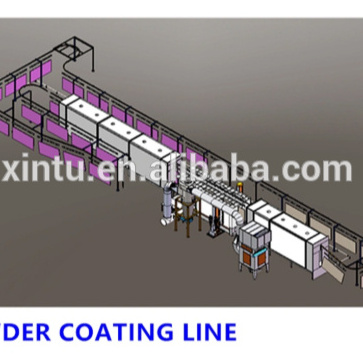

Automatic MDF Board Multi color Powder Coating Line

2.MAIN SYSTEM

| System | Technical Process and Options |

| Pretreatment | Washing, degreasing, etching, phosphating, blasting |

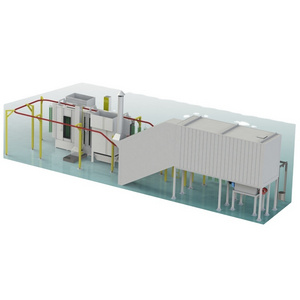

| Drying&Curing Ovens | Tunnel ovens, bridge ovens |

| powder Coating System | Manual or automatic with powder recycle system |

| Transport system | Chain conveyor, power and free conveyor |

3.TECHNOLOGY PROCESS

LOADING>PRETREATMENT>SPRAYING>CURING>COOLING>UNLOADING

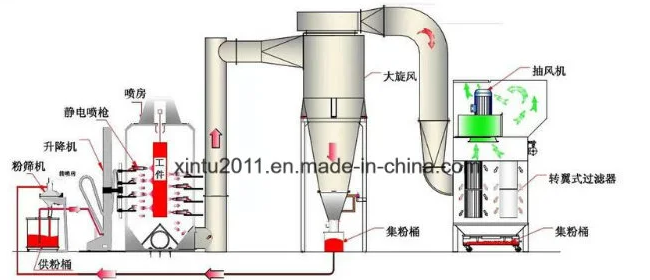

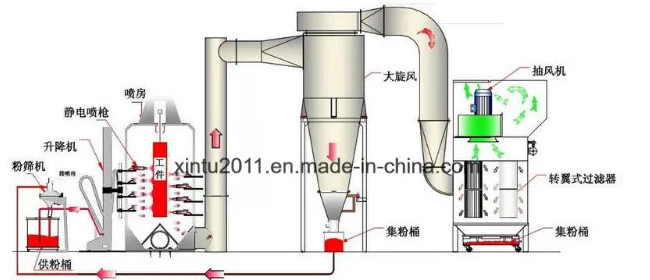

3.INTRODUCTION OF SPRAY PARTS OF LINE

3.1 PRETREATMENT

| Material | stainless steel |

| size | according to actual needs |

| weight | according to the system |

| ways | sanding,spray the primer,heating |

| Material | cold-rolled sheet/stainless steel/PP(PP is best choice especially for the MDF coating) |

| size | Acoording to your output |

| power | according to the actual need |

| powder coating gun |

1.the amount according to the size and output 2.our gun is high efficient as gema powder coating gun |

| reciprocator | 1.stroke hight:1500/2000/2500mm or customized higher one |

| recycle | filter/multi-pipe cyclone with secondary recycle/mono-cyclone with secondary |

| Color change | it is available by us with 3-5 colors |

| powder supply | 1.normal huge powder hopper or powder center(powder center is very high efficient |

| Material | gavalnized sheet/stainless steel |

| burner | natural gas burner/LPG burner/diesel burner |

| RT | 250°C |

| Rock wool | 120mm 150kgs/150mm 200kgs |

| temperature fluctuation | ±5 °C |

| burner brand | Italy Riello |

| temperature control | sensor is available |

| Chain | QXG series |

| track | QXG series |

| Drive | China or Chinese Taiwan Brand |

| hanger | according to your products' size and shape |

| Tensioner | Heavy Hammer/Spring-loaded |

| Accumulation chain | Available if possible |

Packaging: 1.Sea-worthy Packaging with carton and wooden case;

2.wrapping film or carton for larges size product;

3.directly loading into container

Shipping: 1.by sea to your nearest seaport;

2.your expected shipping way is also OK.

Have you exported to any other country?Please show me your customers.

Yes, We have exported to many countries.