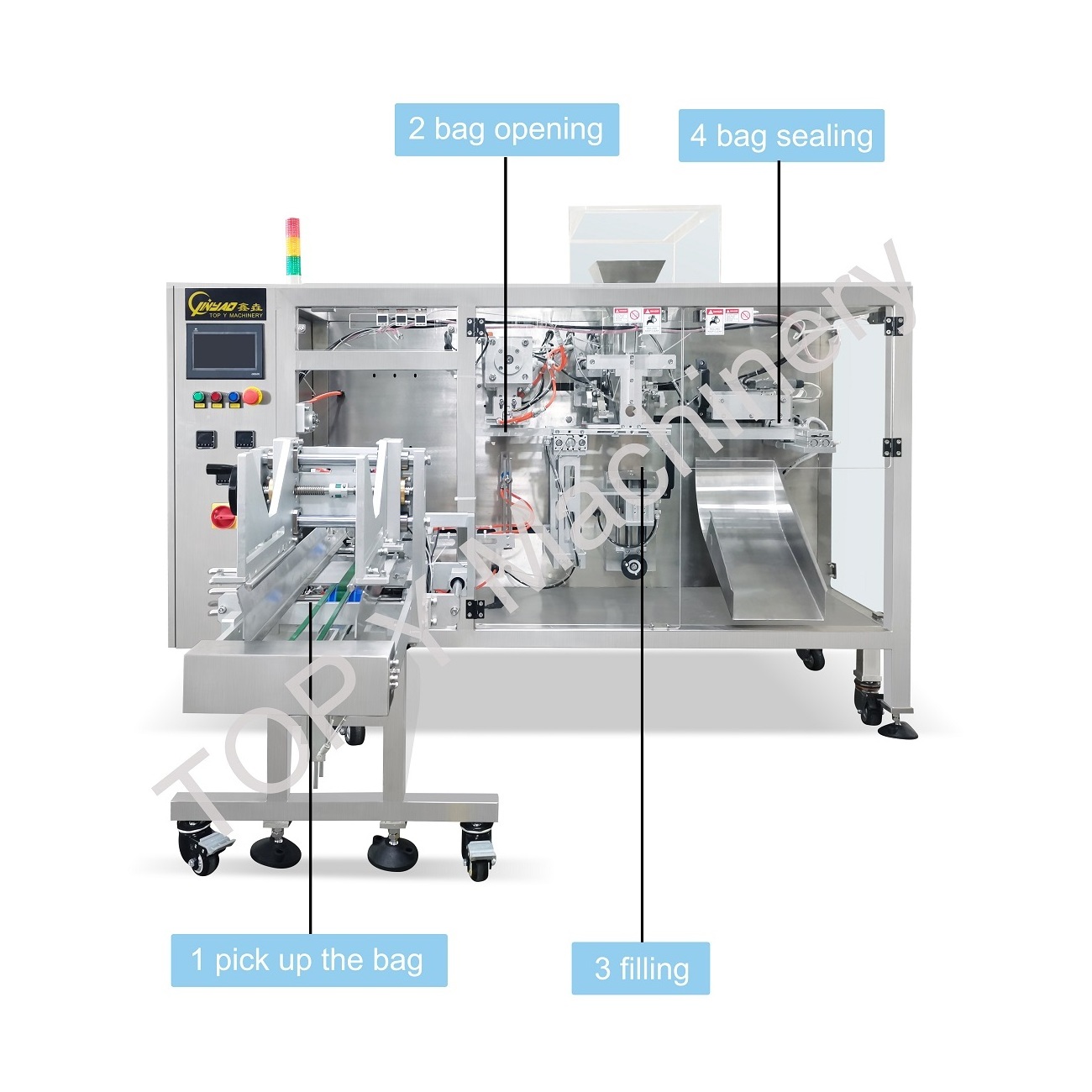

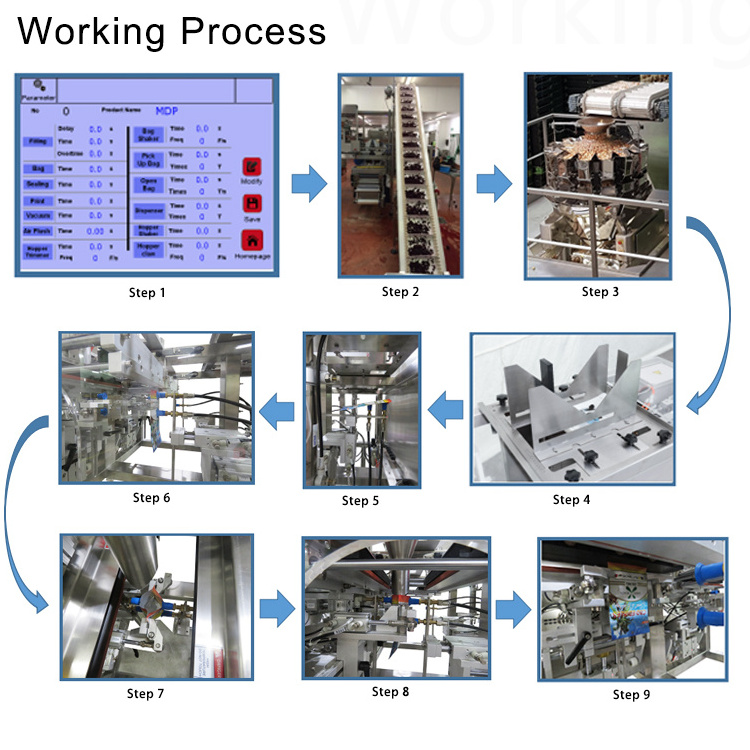

Step1

: set the parameters we need on HMI

Step2

: pour bulk products into the storage hopper manually or automatically

Step3

: multifunction weighing dosing machine will dose target weight we need

Step4

: put bags into bag feeder

Step5

: zipper device open the ziplock

Step6

: positioning bags to the filling station

Step7

: bag open and sending out “request filling” signal

Step8

: filling machine drop down products with target weight into open bags

Step9

: the sealing jaws seal bags automatically

- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

400

-

Voltage:

-

220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

TOP Y Machinery

-

Dimension(L*W*H):

-

2000*800*1500mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Series:

-

Horizontal Packing Machine

-

Usage:

-

weighing, filling, sealing

-

Packing material:

-

OPP/CPP PT/PE KOP/CPP ALU/Filter Paper

-

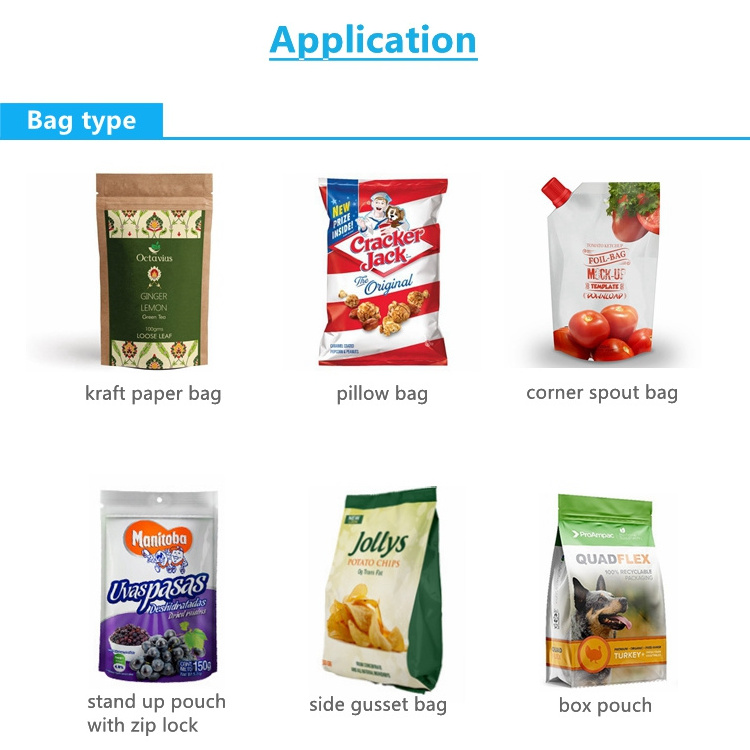

Bag type:

-

zipper bag, stand up pouch, paper bag

-

Bag width:

-

120-400mm

-

Bag length:

-

80-300mm

-

Weigher:

-

linear weigher

-

Packing speed:

-

15-20bags/min

Quick Details

-

Function:

-

FILLING, Sealing

-

Packaging Type:

-

Stand-up Pouch, Bags, Pouch

-

Packaging Material:

-

Plastic, Wood

-

Weight (KG):

-

400

-

Voltage:

-

220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

TOP Y Machinery

-

Dimension(L*W*H):

-

2000*800*1500mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Series:

-

Horizontal Packing Machine

-

Usage:

-

weighing, filling, sealing

-

Packing material:

-

OPP/CPP PT/PE KOP/CPP ALU/Filter Paper

-

Bag type:

-

zipper bag, stand up pouch, paper bag

-

Bag width:

-

120-400mm

-

Bag length:

-

80-300mm

-

Weigher:

-

linear weigher

-

Packing speed:

-

15-20bags/min

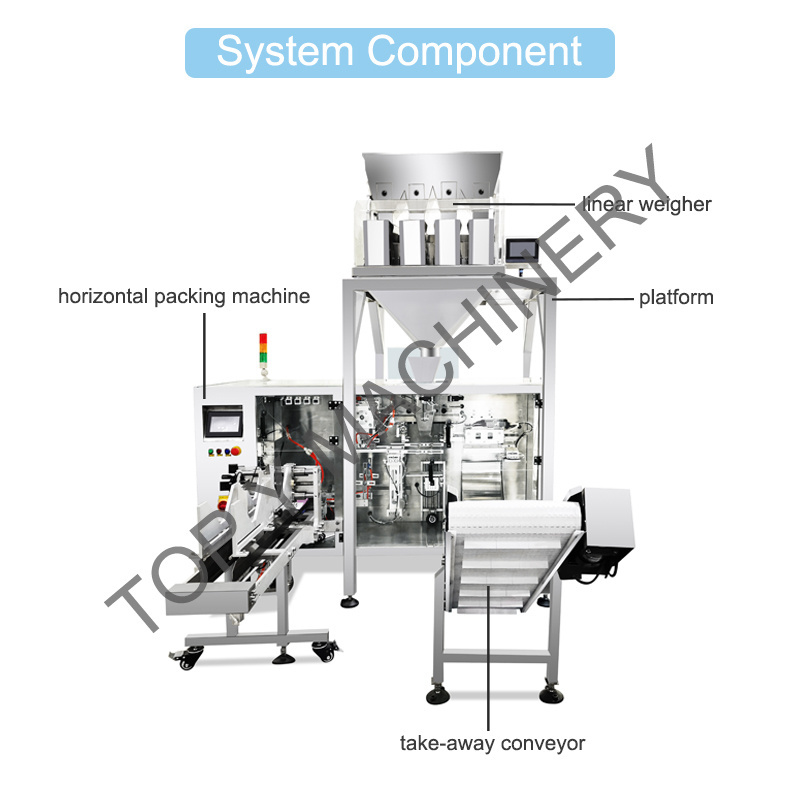

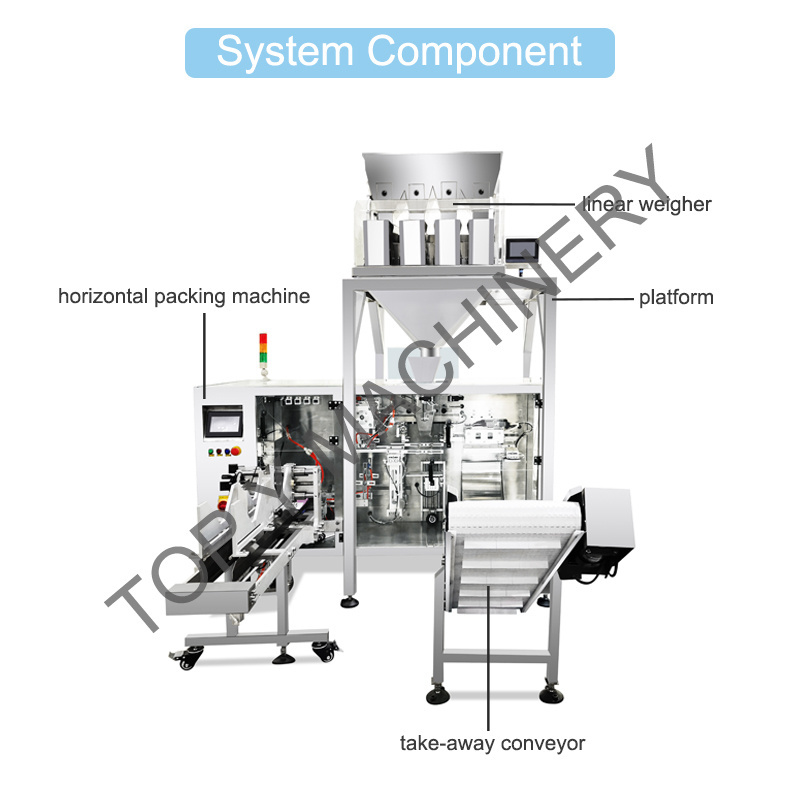

Automatic weighing and packing system for your current and future needs! The functions of the packing system mainly are conveying, weighing, filling and bag sealing. Realize

automatization, save labor and increase the output.

The flexibility of it allows us to customize the most suitable machine to meet your individual requirements!

A. Powder Packing Solution

Servo Screw Auger Filler is specialized for powder filling such as nutrients powder, seasoning powder,

flour, medicinal powder, etc.

B. Liquid Packing Solution

Piston Pump Filler is specialized for liquid filling such as water, juice, laundry detergent, ketchup etc.

C. Solid Packing Solution

Combination multi-head weigher is specialized for solid filling such as candy, nuts, pasta, dried fruit and vegetable etc.

D. Granule Packing Solution

Linear weigher is specialized for granule filling such as chemical, beans, salt, seasonings etc.

flour, medicinal powder, etc.

B. Liquid Packing Solution

Piston Pump Filler is specialized for liquid filling such as water, juice, laundry detergent, ketchup etc.

C. Solid Packing Solution

Combination multi-head weigher is specialized for solid filling such as candy, nuts, pasta, dried fruit and vegetable etc.

D. Granule Packing Solution

Linear weigher is specialized for granule filling such as chemical, beans, salt, seasonings etc.

Granules Weighing and Packing Solution

Combine with the mutilhead weigher, this system can handle various granules, like sugar, rice, beans, nuts, etc

Weighing accuracy: 0.1-1.5g

Speed: 15-20bags/min

Material: Full SS#304(food grade)

Weighing accuracy: 0.1-1.5g

Speed: 15-20bags/min

Material: Full SS#304(food grade)

Bag dimension:

adjustable

Bag type:

all kinds of premade pouched

Product Paramenters

Speed

1. Highest speed can reach 20bags/min

2. It can be adjusted according to filling time

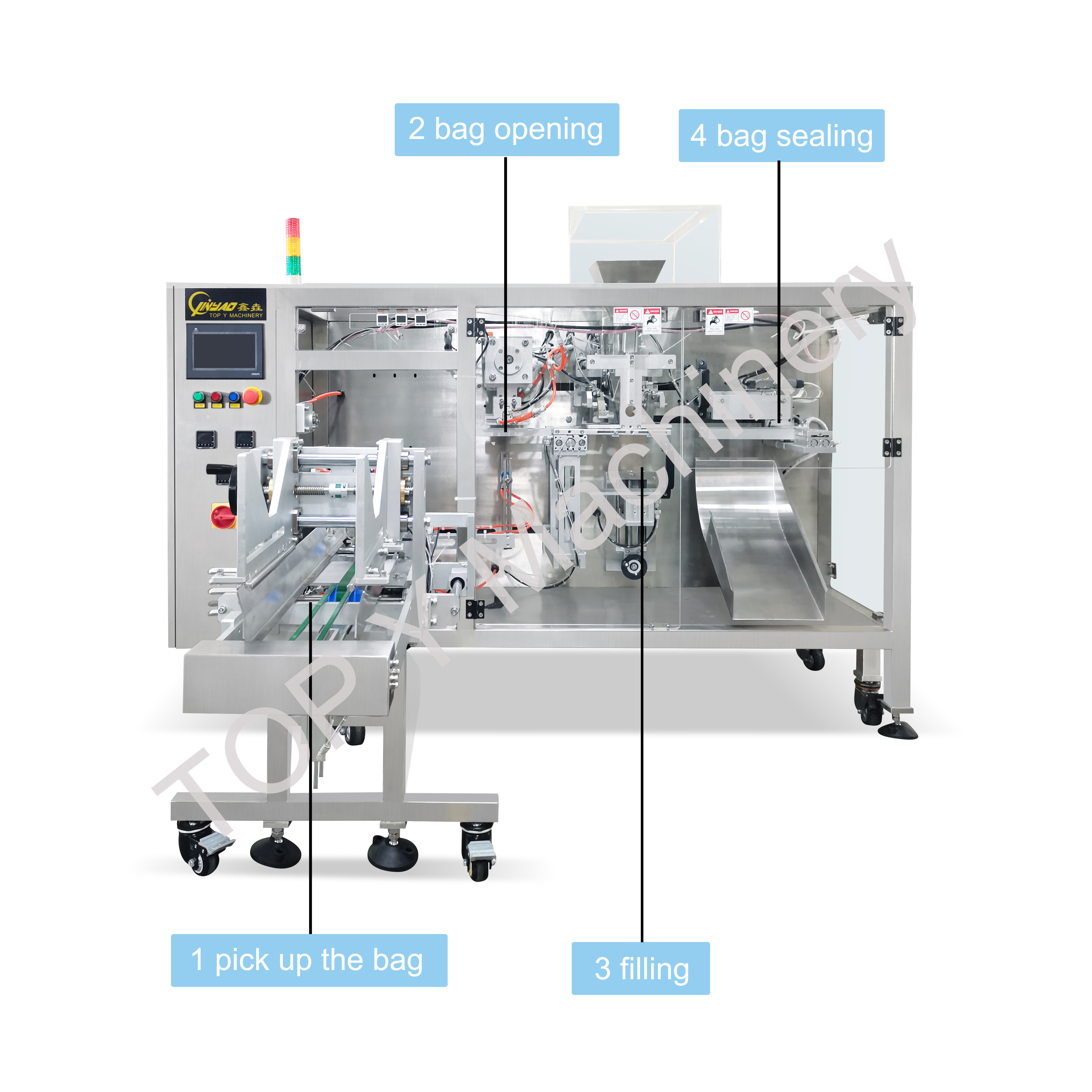

Bag feeder and bag picking up station

1. Flexible enough to fit different bag dimensions

2. Use the high quality suction cup to pick up the bag

Bag opening station

1. Driven by servo motor, easy to adjust

2. Choose the suitable suction cup according to bag material

Bag sealing station

1. Adjustable

temperature

2 Sealing type:

heat seal/ultrasonic seal/ sewing

|

Specifications

|

|

|

|

|||

|

Model No.

|

TOPY-MDPL1

|

TOPY-MDPL2

|

TOPY-MDPL3

|

|||

|

Bag Width

|

80-200mm

|

80-280mm

|

80-330mm

|

|||

|

Bag Length

|

120-300mm

|

120-400mm

|

120-500mm

|

|||

|

Bag Type

|

Stand-up bag, pillow bag, zipper bag, box pouch

|

|

|

|||

|

Power Supply

|

110V/220V/380V/415V, 50/60HZ, 2500w

|

|

|

|||

|

Air Consumption

|

2.0 CFM@80 PSI

|

|

|

|||

|

GW

|

400kg

|

|

|

|||

Suitable bag type

Contact Us

Certifications

Customers & Our Team

Hot Searches