- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V50HZ

-

Power:

-

8KW

-

Weight:

-

1000 KG

-

Dimension(L*W*H):

-

L 2000mm *W 1200mm *H1800mm

-

Product name:

-

Retort Sterilizer

-

Keywords:

-

Autoclave Retort Sterilizer

-

Application:

-

Food Products

-

Heating way:

-

Hot Water Heating

-

Function:

-

Sterilzation

-

Advantage:

-

high efficiency

-

Sterilizing Type:

-

water sterilizing

-

Feature:

-

Low Energy High Efficiency

-

Brand:

-

Inchoi

-

Suitable for:

-

food industry

Quick Details

-

Marketing Type:

-

New Product 2021

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Inchoi

-

Voltage:

-

380V50HZ

-

Power:

-

8KW

-

Weight:

-

1000 KG

-

Dimension(L*W*H):

-

L 2000mm *W 1200mm *H1800mm

-

Product name:

-

Retort Sterilizer

-

Keywords:

-

Autoclave Retort Sterilizer

-

Application:

-

Food Products

-

Heating way:

-

Hot Water Heating

-

Function:

-

Sterilzation

-

Advantage:

-

high efficiency

-

Sterilizing Type:

-

water sterilizing

-

Feature:

-

Low Energy High Efficiency

-

Brand:

-

Inchoi

-

Suitable for:

-

food industry

Product Description

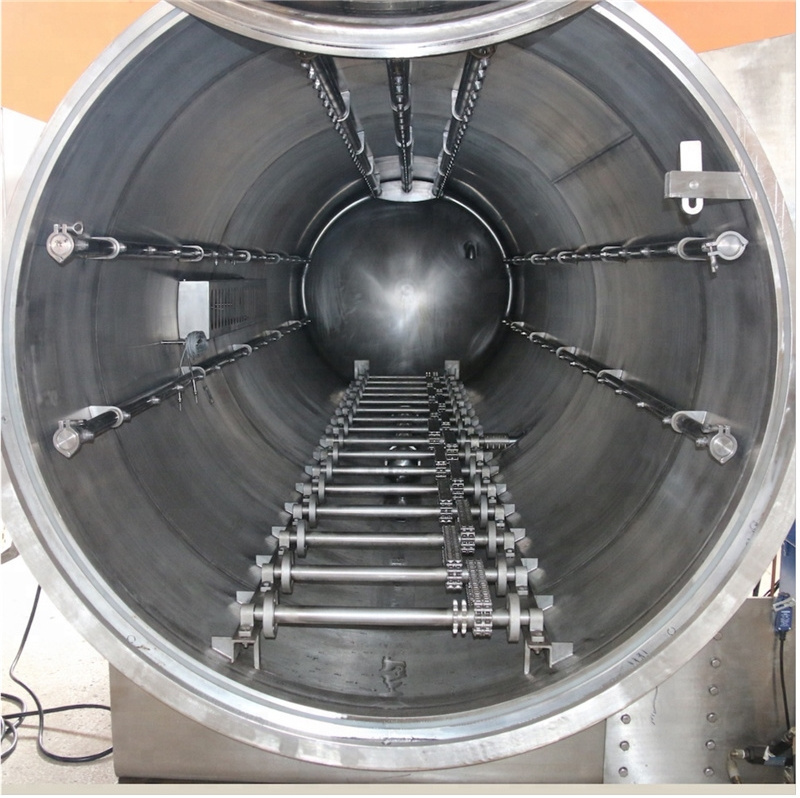

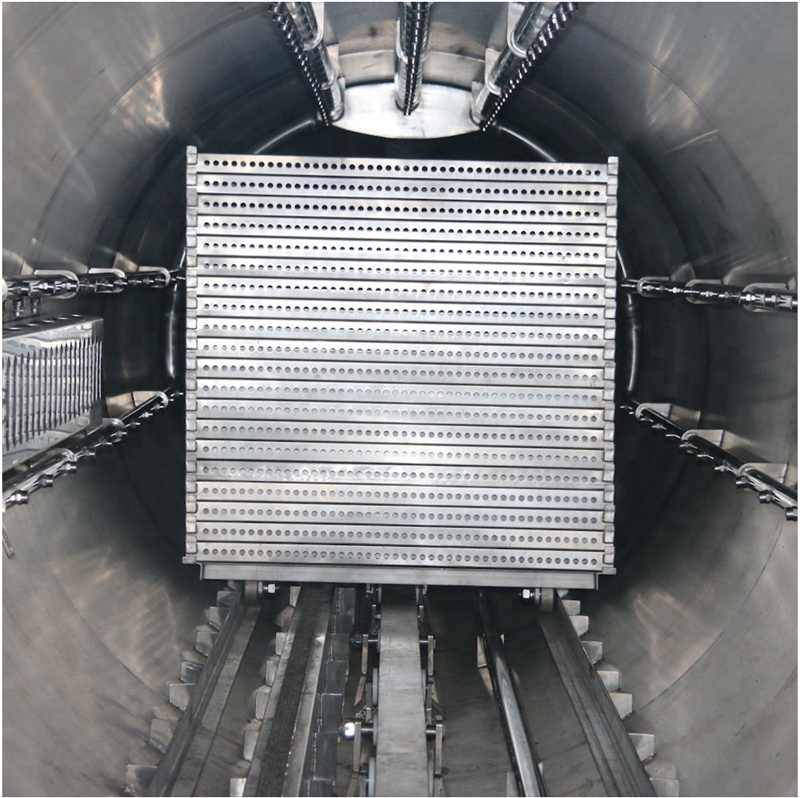

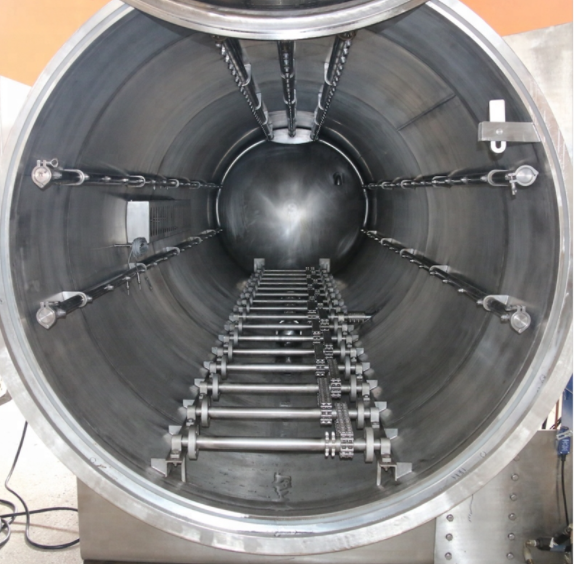

The machine is adjustable according to the product to be processed,and the space between nozzles are also customizable according to the height of production. By employing the precise spraying method in the direction of the nozzle, we aim to ensure the precise and uniform heated water dispersion all the way to the center of each tray.

Details Images

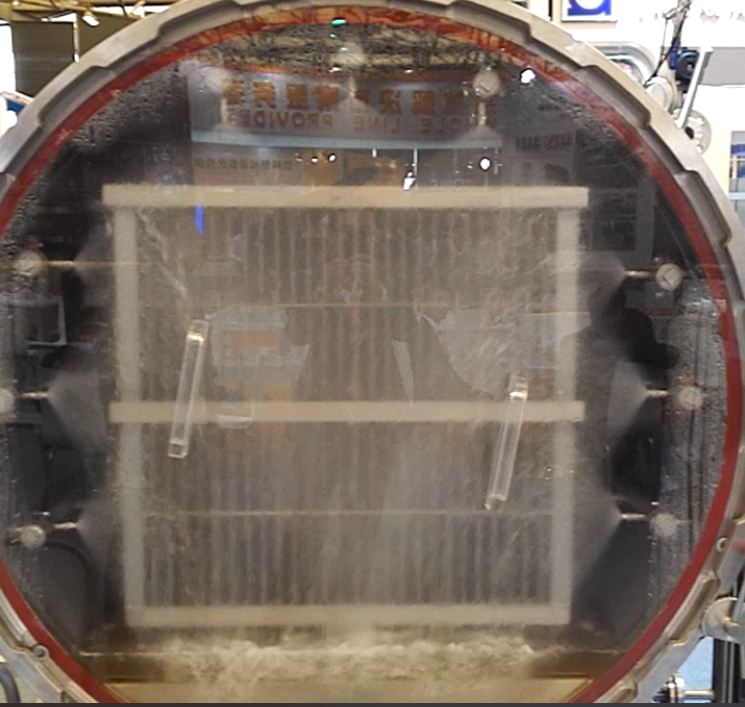

The Water Spray process is also an overpressure process, like water immersion, except that the product is exposed to the influence of the overpressure air. It is similar to the Saturated Steam process in that steam is the driving force for reaching the center of the load. But, the Water Spray process is different from Saturated Steam in that air can be introduced into the vessel during sterilization. Overpressure is provided by introducing air (or steam) into the retort. To overcome the insulating effects of the air, the spray nozzles vaporize the steam and mix the steam with the air.

Product Features

1.The Hot Water Spray Retorts allow for pasteurization with minimum process water, direct heating and indirect cooling. These will be no touch between cooling water and process water, successfully avoiding secondary contamination.

2.The Hot Water Spray Retorts also boast perfect pressure control. During the whole processing procedure, the pressure is

constantly adjusted to adapt to the changing pressure inside product package. They ideally keep package deformation to a minimum, well suitable for Gas packaging and two piece can packaging.

3.The noise of Hot Water rain retorts is extremely low creating a quiet and comfortable working environment.

4.The advanced and suitable DELTA PLC control system ensures our clients are able to timely locate replacement parts of the batch retorts across the world reducing down time.

5.The Hot Water Spray Retort / Sterilization equipment makes it convenient to configure automatic corollary equipment for unmanned food workshops in the future.

6.The whole sterilization process adopts PLC fully automatic linearity control via the PLC control, the temperature difference of thermal distribution is limited within ± 0.5C. The Hot Water Spray Retort Steriliser allow for multi-stage heating, effectively

saving energy. It also has an additional F value recorder (optimal) capable of storing 100 scheduled processes

2.The Hot Water Spray Retorts also boast perfect pressure control. During the whole processing procedure, the pressure is

constantly adjusted to adapt to the changing pressure inside product package. They ideally keep package deformation to a minimum, well suitable for Gas packaging and two piece can packaging.

3.The noise of Hot Water rain retorts is extremely low creating a quiet and comfortable working environment.

4.The advanced and suitable DELTA PLC control system ensures our clients are able to timely locate replacement parts of the batch retorts across the world reducing down time.

5.The Hot Water Spray Retort / Sterilization equipment makes it convenient to configure automatic corollary equipment for unmanned food workshops in the future.

6.The whole sterilization process adopts PLC fully automatic linearity control via the PLC control, the temperature difference of thermal distribution is limited within ± 0.5C. The Hot Water Spray Retort Steriliser allow for multi-stage heating, effectively

saving energy. It also has an additional F value recorder (optimal) capable of storing 100 scheduled processes

Guidelines for using

1. Put the filled products into baskets, then send them to sterilization retort. Then close the retort door. The door is safety

interlock to ensure safety. And the door is locked in a mechanical way during the entire process of sterilization. Sterilization process is carried out automatically in accordance with the data input to microprocessor controller PLC.

3. The heat exchanger of retort is used for heating or cooling phase, where process water goes through one side of it, and the cooling water flows through the other side, so that the sterilized product is not in direct contact with cooling water to

achieve sterility cooling.

4. Throughout the process, the pressure inside the retort is controlled by a program which controls two automatic valves to

feed or discharge compressed air in or from retort. As it is water spray sterilization, pressure in retort is independent of

temperature and can be set freely depending on the product packaging to make more extensive use of the equipment (boxed, three-piece cans, two-piece cans, flexible packaging bags, bottles, etc. while adapting).

5. By the end of the sterilization, alarm signal will be displayed. It is time to open the door and unload. Then prepare the next batch products for sterilization.

6. The temperature distribution uniformity of retort are + / - 0.5 ° C

interlock to ensure safety. And the door is locked in a mechanical way during the entire process of sterilization. Sterilization process is carried out automatically in accordance with the data input to microprocessor controller PLC.

3. The heat exchanger of retort is used for heating or cooling phase, where process water goes through one side of it, and the cooling water flows through the other side, so that the sterilized product is not in direct contact with cooling water to

achieve sterility cooling.

4. Throughout the process, the pressure inside the retort is controlled by a program which controls two automatic valves to

feed or discharge compressed air in or from retort. As it is water spray sterilization, pressure in retort is independent of

temperature and can be set freely depending on the product packaging to make more extensive use of the equipment (boxed, three-piece cans, two-piece cans, flexible packaging bags, bottles, etc. while adapting).

5. By the end of the sterilization, alarm signal will be displayed. It is time to open the door and unload. Then prepare the next batch products for sterilization.

6. The temperature distribution uniformity of retort are + / - 0.5 ° C

Specification

|

item

|

value

|

|

Applicable Industries

|

Hotels, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Food & Beverage Shops

|

|

After Warranty Service

|

Video technical support, Online support, Spare parts

|

|

Local Service Location

|

Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Philippines, Brazil, Peru, Indonesia, India, Mexico, Russia, Spain, Thailand, Japan, Malaysia, Australia, South Korea, South Africa

|

|

Showroom Location

|

Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Philippines, Brazil, Peru, Indonesia, India, Mexico, Russia, Spain, Thailand, South Korea, Romania, South Africa, Japan, Australia

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Marketing Type

|

New Product 2020

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

Motor

|

|

Condition

|

New

|

|

Place of Origin

|

China

|

|

Brand Name

|

Inchoi

|

|

Voltage

|

380V50HZ

|

|

Power

|

8KW

|

|

Weight

|

1T

|

|

Dimension(L*W*H)

|

L 2000mm *W 1200mm *H1800mm

|

|

Certification

|

CE

|

|

Warranty

|

1 Year

|

|

|

Online support

|

|

Key Selling Points

|

High Productivity

|

|

Product name

|

Retort Sterilizer

|

|

Keywords

|

Autoclave Retort Sterilizer

|

|

Application

|

Food Products

|

|

Heating way

|

Hot Water Heating

|

|

Function

|

Sterilzation

|

|

Advantage

|

high efficiency

|

|

Sterilizing Type

|

water sterilizing

|

|

Feature

|

Low Energy High Efficiency

|

|

Brand

|

Inchoi

|

|

Suitable for

|

food industry

|

Packing & Delivery

Machine packaging with plastic film and fixed by steel wire in the container.

Hot Searches