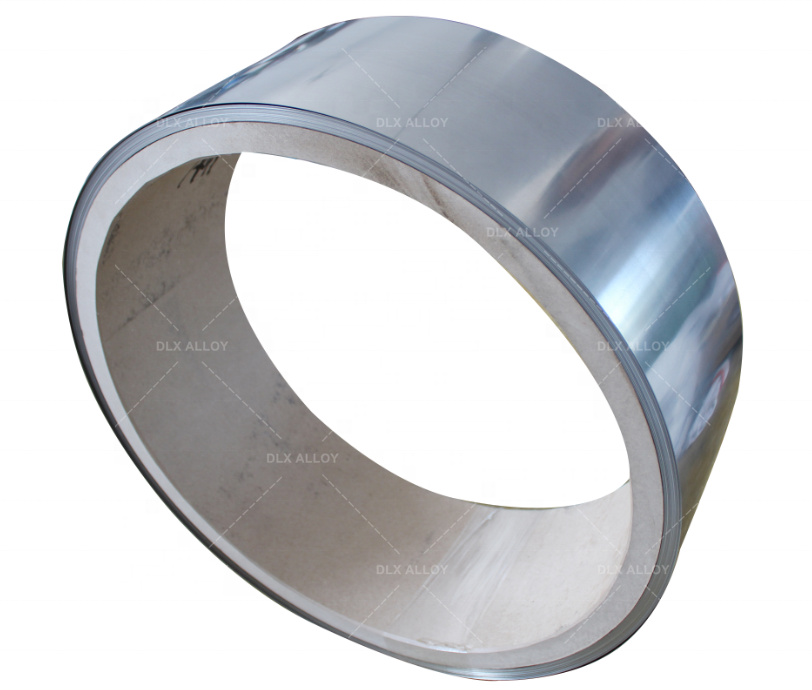

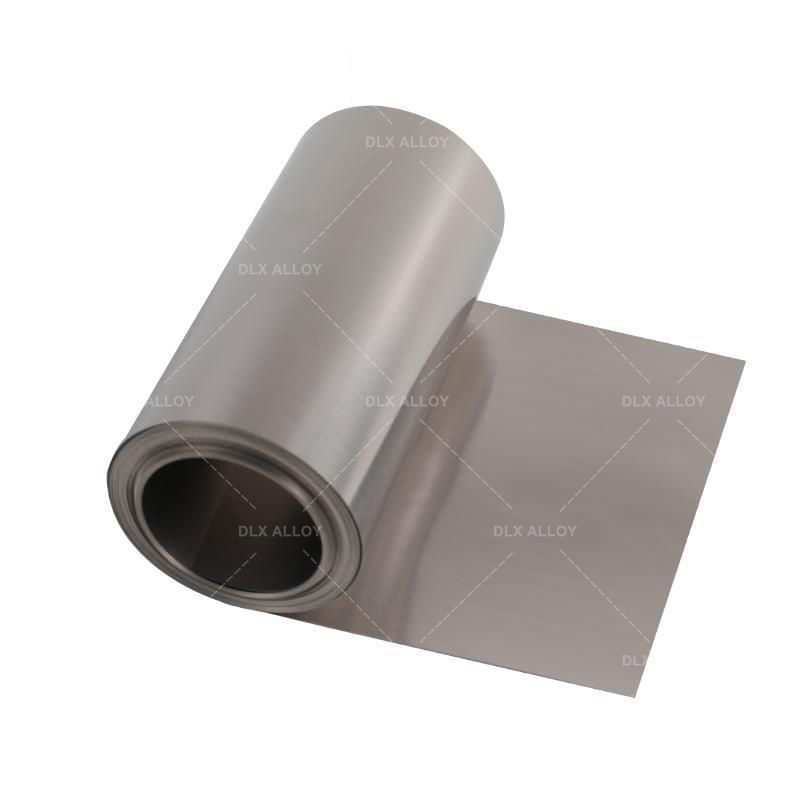

* Thickness - 0.001” (0.05 mm) to 0.138” (3.5 mm)

* Width - 0.118” (3 mm) to 13.50” (380mm)

* Coil Sizes offered (Inside diameter): 300, 400 & 500 mm

- Product Details

- {{item.text}}

Quick Details

-

Elongation (≥ %):

-

40%

-

Place of Origin:

-

Jiangsu, China

-

Application:

-

used in chemical, oil, Marine industry

-

Grade:

-

Ni Cr Mo

-

Ni (Min):

-

58%

-

Model Number:

-

Hatelloy N Strip

-

Brand Name:

-

DXL

-

Chemical Composition:

-

Ni Cr Mo

-

Outer Diameter:

-

10.3mm~324mm

-

Thickness:

-

1mm~30mm

-

Density:

-

8.9 g/cm3

-

Melting point:

-

1325-1370 ℃

-

Tensile strength Rm(N/mm2):

-

≥690

-

Yield strength Rm(N/mm2):

-

283

-

Elongation(%):

-

≥40

-

Product name:

-

Hastelloy N strip

-

Material:

-

Nickle Alloy Material

Quick Details

-

Resistance (μΩ.m):

-

1.5

-

Powder Or Not:

-

Not Powder

-

Ultimate Strength (≥ MPa):

-

690

-

Elongation (≥ %):

-

40%

-

Place of Origin:

-

Jiangsu, China

-

Application:

-

used in chemical, oil, Marine industry

-

Grade:

-

Ni Cr Mo

-

Ni (Min):

-

58%

-

Model Number:

-

Hatelloy N Strip

-

Brand Name:

-

DXL

-

Chemical Composition:

-

Ni Cr Mo

-

Outer Diameter:

-

10.3mm~324mm

-

Thickness:

-

1mm~30mm

-

Density:

-

8.9 g/cm3

-

Melting point:

-

1325-1370 ℃

-

Tensile strength Rm(N/mm2):

-

≥690

-

Yield strength Rm(N/mm2):

-

283

-

Elongation(%):

-

≥40

-

Product name:

-

Hastelloy N strip

-

Material:

-

Nickle Alloy Material

Hastelloy HC-276/C-22/C-4/B2/B3/N Strip

What is Hastelloy C276 used for?

Hastelloy C276 is a nickel-molybdenum-chromium alloy that is highly corrosion-resistant and is used in a variety of industries.

Some common applications of Hastelloy C276 include:

1. Chemical Processing: It is widely used in chemical reactors, vessels, and piping systems that handle corrosive chemicals such as sulfuric acid, hydrochloric acid, acetic acid, and phosphoric acid.

2. Petrochemical Industry: Hastelloy C276 is used in equipment like heat exchangers, valves, and pumps that are exposed to corrosive environments in the oil and gas industry.

3. Power Generation: It is used in flue gas desulfurization systems, scrubbers, and other equipment that come in contact with corrosive gases and liquids in power plants.

4. Pharmaceutical Industry: Hastelloy C276 is used in the production of pharmaceutical drugs where corrosion resistance is crucial, especially in the presence of acids and chlorides.

5. Pollution Control: It is used in pollution control equipment like stack liners, ducts, and dampers to resist corrosion caused by acidic gases and other pollutants.

6. Aerospace Industry: Hastelloy C276 is used in aircraft and aerospace applications, particularly in the construction of engine components, due to its high strength and resistance to corrosion.

7. Marine Industry: It finds use in seawater cooling systems, desalination plants, and other marine applications where resistance to chloride-induced corrosion is necessary.

Overall, Hastelloy C276 is chosen for its exceptional corrosion resistance in a wide range of aggressive environments, making it suitable for various industries where corrosion is a concern.

HASTELLOY is a Nickel-chromium-molybdenum wrought alloy that is considered the most versatile corrosion resistant alloy available.

Some common applications of Hastelloy C276 include:

1. Chemical Processing: It is widely used in chemical reactors, vessels, and piping systems that handle corrosive chemicals such as sulfuric acid, hydrochloric acid, acetic acid, and phosphoric acid.

2. Petrochemical Industry: Hastelloy C276 is used in equipment like heat exchangers, valves, and pumps that are exposed to corrosive environments in the oil and gas industry.

3. Power Generation: It is used in flue gas desulfurization systems, scrubbers, and other equipment that come in contact with corrosive gases and liquids in power plants.

4. Pharmaceutical Industry: Hastelloy C276 is used in the production of pharmaceutical drugs where corrosion resistance is crucial, especially in the presence of acids and chlorides.

5. Pollution Control: It is used in pollution control equipment like stack liners, ducts, and dampers to resist corrosion caused by acidic gases and other pollutants.

6. Aerospace Industry: Hastelloy C276 is used in aircraft and aerospace applications, particularly in the construction of engine components, due to its high strength and resistance to corrosion.

7. Marine Industry: It finds use in seawater cooling systems, desalination plants, and other marine applications where resistance to chloride-induced corrosion is necessary.

Overall, Hastelloy C276 is chosen for its exceptional corrosion resistance in a wide range of aggressive environments, making it suitable for various industries where corrosion is a concern.

This alloy is resistant to the formation of grain boundary precipitates in the weld heat-affected zone, thus making it suitable for most chemical process applications in an as welded condition.Hastelloy Form: Pipe / Tube (welded and seamless), Plate / Sheet,Bar, Wire, Fittings

Wire: 0.01-10mm

Strip: 0.05*5.0-5.0*250mm

Bar: φ4-50mm;Length 2000-5000mm

Pipe: φ6-273mm;δ1-30mm;Length 1000-8000mm

Sheet: δ 0.8-36mm;Width 650-2000mm;Length 800-4500mm

|

Name

|

Hastelloy C22(N06022/2.4602/NS3308)

|

|

|

||

|

Chemmical Compsition wt.%

|

Ni

|

min.margin

|

max.margin

|

||

|

|

Fe

|

min.2

|

max.6

|

||

|

|

C

|

min.-

|

max.0.015

|

||

|

|

Mn

|

min.-

|

max.0.5

|

||

|

|

P

|

min.-

|

max.0.02

|

||

|

|

Si

|

min.-

|

max.0.08

|

||

|

|

Mo

|

min.12.5

|

max.14.5

|

||

|

|

W

|

min.2.5

|

max.3.5

|

||

|

|

Co

|

min.-

|

max.2.5

|

||

|

|

S

|

min.-

|

max.0.02

|

||

|

|

V

|

min.-

|

max.0.35

|

||

|

|

Cr

|

min.20

|

max.22.5

|

||

|

Product

|

nickel alloy sheet

|

|

Material

|

Hastelloy/Nickel Alloy strip

|

|

Grade

|

Hastelloy:HastelloyB/ -2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N/g Hastelloy B / UNS N10001,Hastelloy B-2 / UNS N10665 / DIN

W.Nr. 2.4617,Hastelloy C, Hastelloy C-4 / UNS N06455 / DIN W. Nr. 2.4610,Hastelloy C-22 / UNS N06022 / DIN W. Nr. 2.4602, Hastelloy C-276 / UNS N10276 / DIN W. Nr. 2.4819,Hastelloy X / UNS N06002 / DIN W. Nr. 2.4665 |

|

Thickness

|

Customized

|

|

Width

|

600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc

|

|

Length

|

2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc

|

|

Standard

|

GB,AISI,ASTM,DIN,EN,SUS,UNS etc

|

|

Quality test

|

we can offer MTC(mill test certificate)

|

|

Delivery time

|

Usually 7-15 dyas, or upon negotiation

|

The application areas of Inconel strip include the following:

Aerospace field: Inconel strip has excellent high-temperature resistance, corrosion resistance, and high-strength characteristics, and is widely used in the aerospace field, such as aircraft engine components, combustion chambers, turbine blades, gas turbines, and so on.

Chemical industry: Inconel strip can maintain good performance in high temperature and corrosive environments, so it is widely used in chemical equipment, petroleum processing devices, refineries, fertilizer plants, and other fields.

Medical field: Inconel strip has good biocompatibility and corrosion resistance, and is therefore used in the manufacturing of medical devices, such as artificial joints, dental devices, implants, etc.

Electronics: Inconel strip has excellent electromagnetic shielding performance and high-temperature stability, making it widely used in electronic equipment, electronic components, semiconductor manufacturing, and other fields.

Automotive field: Inconel strip is increasingly widely used in automotive exhaust systems, such as exhaust pipes and turbochargers, as it can withstand the erosion of high temperatures and corrosive gases.

In summary, Inconel strip has a wide range of applications, mainly concentrated in areas that require high temperature resistance, corrosion resistance, and high strength, such as aerospace, chemical, medical, electronics, and automobiles.

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate

Our Advantage

1.Market Leader

Top 5 in China's nonferrous metal industry

2.Flexible products

Thousands of product specifications,Meet multiple needs of buyers

3.Low MOQ

Can customize samples

4.Short production lead time,fast delivery of whole cabinet

5.Professional inspection equipment

Before delivery, we will use spectrometers, tensile testers and other professional equipment to conduct a comprehensive inspection of the products to ensure that the goods are qualified for acceptance

6.Professional business team

Quickly responds to customer inquiries,24-hour professional quotation online

The salesperson will follow the customer's requirements for the use of the product,Professionally recommend more appropriate performance and price products to customers

7.Intact packaging

Packaging according to customer needs.You can customize wooden boxes to ensure that the goods arrive at the destination in good condition

8.Various payment methods

Facilitate customer payment

9.Get good reviews from customers

Old customers have long-term cooperation,The longest is more than 7 years

10.Received various awards

Google is very recognized by us,They give us awards every year

Customer first and Best price offer!

Oem service:

Welcome customized size

We are experience factory for OEM&ODM service

After sale service:

24 hours on alibaba for after sale service

Alibaba trade assurance

Oem service:

Welcome customized size

We are experience factory for OEM&ODM service

After sale service:

24 hours on alibaba for after sale service

Alibaba trade assurance

Packing&Shipping

Recommend Products

Hot Searches