- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

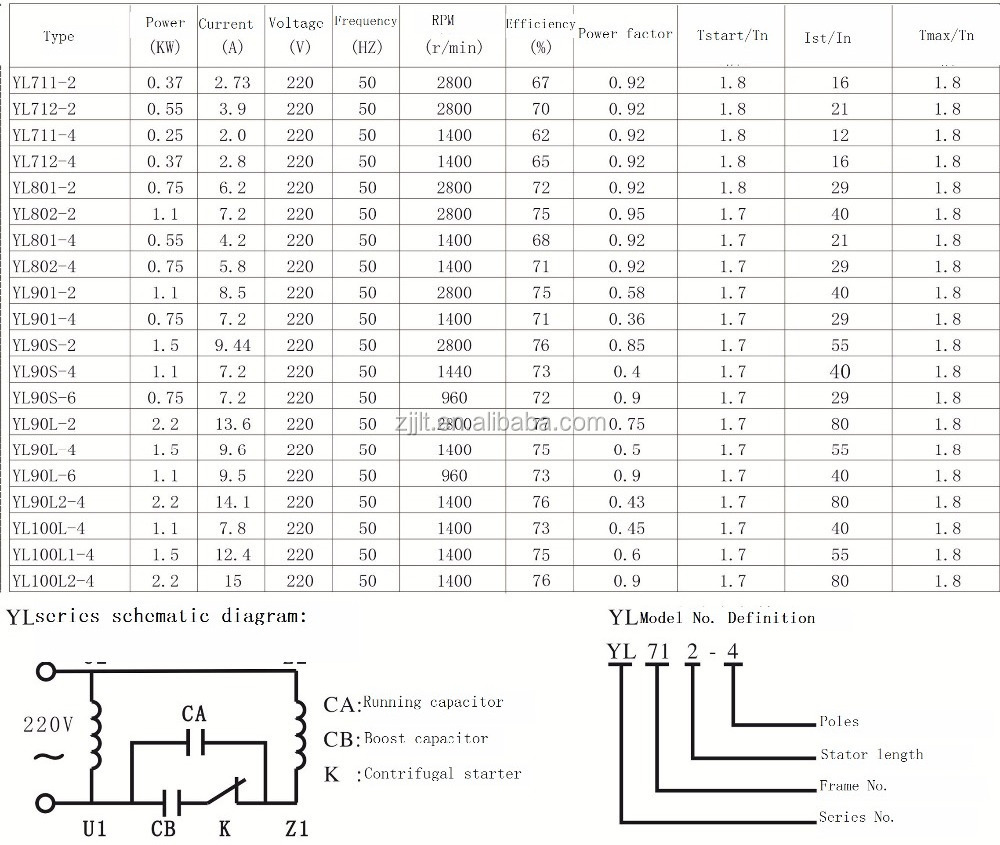

YL

-

Frequency:

-

50/60Hz

-

Certification:

-

CCC

Quick Details

-

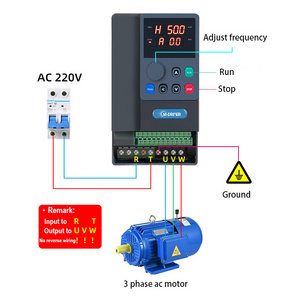

AC Voltage:

-

208-230 / 240 V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

JULANTE

-

Model Number:

-

YL

-

Frequency:

-

50/60Hz

-

Certification:

-

CCC

our Taizhou Julante Factory is Specialized in ind uction Motor Production

Welcome to visit our website. http://www.zjjlt.en.alibaba.com/

We are a manufacturer but we can also supply the OEM service, products can be customized.

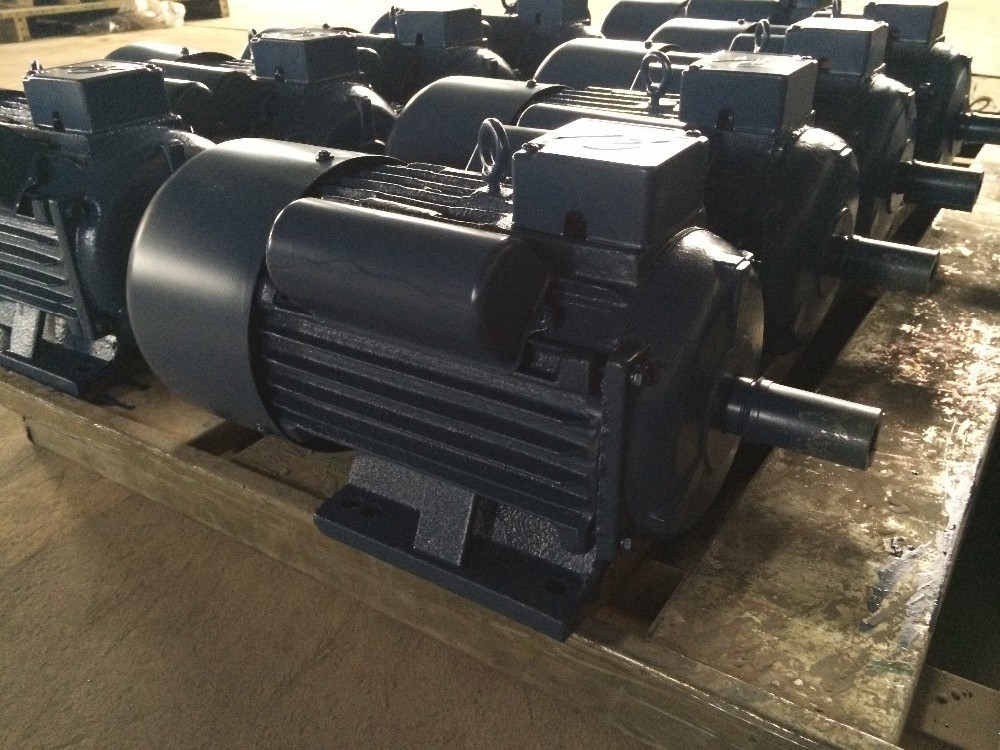

Inner packing:

1) Frame 63-100: carton boxes

2) Frame 112-315: wooden boxes

Mounting ways:

IMB3(foot mounting),IMB5(flange mounting),IMB35,IMB14.

BENIFITS TO CLIENT:

- Reliable operation

- High efficiency

- Energy-saving

- Low noise

- Long life

- Slight vibration

- Try our best to meet customers' requirements, including voltage and frequency etc.

- It is newly designed in conformity with the relevant rules of IEC standards

- Special rotor balance for reduced vibration

- Warranty: 12 months from date of delivery.

OPERATION CONDITIONS:

- Duty: S1

- Frequency: 50HZ

- Rated voltage: 220V±5%

- Protection class: IP55

- Cooling method: IC0141

- Ambient temperature: -15°C≤0≤45°C

-

Alititude should be lower than 1000 meters above sea level

OPERATION CONDITIONS:

- Duty: S1

- Frequency: 50HZ

- Rated voltage: 220V±5%

- Protection class: IP55

- Cooling method: IC0141

- Ambient temperature: -15°C≤0≤45°C

- Alititude should be lower than 1000 meters above sea level

China Julante Motors Factory Advantages:- Prompt Quotation.

- Competitive Price

- Guaranteed Quality

- Timely Delivery

- 100% Tested.

- Sincere and Professional Service.

- Outstanding Finishing Surface.

- Strictly and Perfect Management is guaranteed for Production.

- Specialized in Manufacturing and Supplying a wide range of Electric Motors since year 2002.

- Have Rich Experience and Strong ability to Develop New Products.

- Have Ability to Design the Products Based on Your Original Samples

Manufacturing process:- Stamping of lamination

- Rotor die-casting

- Winding and inserting – both manual and semi-automatically

- Vacuum varnishing

- Machining shaft, housing, end shields, etc…

- Rotor balancing

- Painting – both wet paint and powder coating

- Motor assembly

- Packing

- Inspecting spare parts every processing

- 100% test after each process and final test before packi