- Product Details

- {{item.text}}

Quick Details

-

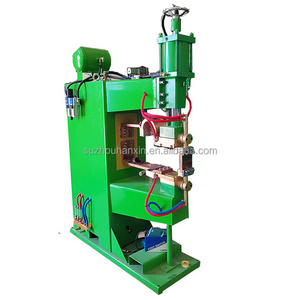

Usage:

-

spot welder

-

Voltage:

-

220V

-

Weight (KG):

-

300 KG

-

input power:

-

3*380V 50-60Hz

-

air source:

-

0.6 Mpa >=19L/min

-

welding temperature:

-

600C

-

program number:

-

60

-

diameter of electrode:

-

6-35mm(outer size)

-

Max power:

-

65 kva (50% duty cycle)

-

working temperature:

-

10-40C

-

welding force:

-

max 1000kg

-

welding time:

-

3-20S

-

Certification:

-

CE

Quick Details

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

MINDERHIGHTECH

-

Usage:

-

spot welder

-

Voltage:

-

220V

-

Weight (KG):

-

300 KG

-

input power:

-

3*380V 50-60Hz

-

air source:

-

0.6 Mpa >=19L/min

-

welding temperature:

-

600C

-

program number:

-

60

-

diameter of electrode:

-

6-35mm(outer size)

-

Max power:

-

65 kva (50% duty cycle)

-

working temperature:

-

10-40C

-

welding force:

-

max 1000kg

-

welding time:

-

3-20S

-

Certification:

-

CE

Why Choose Us

Our inverter DC spot welding technology can fully reach the international technical level, which can replace the "soldering" and "riveting" in precision welding of many metals, and can better solve many welding difficulties and improve the process.

We have many senior experts in the welding industry, skilled in craftsmanship, and can provide long-term and perfect technological services.

Pre-sale and after-sale technical support, 7*24 hours engineer service online.

Complete product technical training to ensure that customers use high-quality and stable equipment.

Pre-sale and after-sale technical support, 7*24 hours engineer service online.

Complete product technical training to ensure that customers use high-quality and stable equipment.

Product Description

Principle:

First, the current goes through the lug, By the heat generated from the lug, the enamel on the wire has been melt and removed, and under the heat and pressure, the wire and lug has been compacted and crimped, so we get good electrical connection between the wires and the crimp lug.

As this need not operator remove the enamel by mechanical or chemical method before compacting, but do it directly at one time, this take good advance efficiency and quality.

As this need not operator remove the enamel by mechanical or chemical method before compacting, but do it directly at one time, this take good advance efficiency and quality.

Features

2KHz inverter frequency, high control response and precision.

The parameter setting and welding process are displayed on the touch screen, which is easy to operate, high in production

efficiency, and has no burrs in shaping.

Pulse width control network voltage compensation; constant current, constant voltage, constant power and constant pulse width control modes.

The applicable wire harness range is 1mm2-20mm2, and the process adaptability is wide. Applicable materials: Red copper, brass, tin-plated & nickel-plated & silver-plated copper and other medical, automotive

electronics and other wiring harness parts.

Welding pressure and displacement monitoring; displacement power-off function to ensure the consistency of type variables.

The upper and lower limits of the monitoring current can be set, and the actual output current exceeds the limit to output an alarm signal, which is convenient for quality management.

RS485 communication interface, real-time communication with PLC, touch screen, PC and other upper computers, which is convenient for system integration and welding process data storage and management.

The parameter setting and welding process are displayed on the touch screen, which is easy to operate, high in production

efficiency, and has no burrs in shaping.

Pulse width control network voltage compensation; constant current, constant voltage, constant power and constant pulse width control modes.

The applicable wire harness range is 1mm2-20mm2, and the process adaptability is wide. Applicable materials: Red copper, brass, tin-plated & nickel-plated & silver-plated copper and other medical, automotive

electronics and other wiring harness parts.

Welding pressure and displacement monitoring; displacement power-off function to ensure the consistency of type variables.

The upper and lower limits of the monitoring current can be set, and the actual output current exceeds the limit to output an alarm signal, which is convenient for quality management.

RS485 communication interface, real-time communication with PLC, touch screen, PC and other upper computers, which is convenient for system integration and welding process data storage and management.

Specification

|

item

|

value

|

|

Applicable Industries

|

Building Material Shops, Machinery Repair Shops, Manufacturing Plant

|

|

After Warranty Service

|

Video technical support, Online support, Spare parts

|

|

Local Service Location

|

United States, Germany, Malaysia

|

|

Showroom Location

|

United States, Germany, Malaysia

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Marketing Type

|

New Product 2020

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

PLC, Engine

|

|

Condition

|

New

|

|

Place of Origin

|

China

|

|

Brand Name

|

MINDERHIGHTECH

|

|

Certification

|

CE

|

|

Warranty

|

1 Year

|

|

|

Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support, Video technical support

|

|

Key Selling Points

|

Competitive Price

|

|

Weight (KG)

|

300KG

|

|

input power

|

3*380V 50-60Hz

|

|

air source

|

0.6 Mpa >=19L/min

|

|

welding temperature

|

600C

|

|

program number

|

60

|

|

diameter of electrode

|

6-35mm(outer size)

|

|

Max power

|

65 kva (50% duty cycle)

|

|

working temperature

|

10-40C

|

|

welding force

|

max 1000kg

|

|

welding time

|

3-20S

|

Sample

Packing & Delivery

plywood

Factory

FAQ

1. who are we?

We are based in Guangdong, China, start from 2014,sell to North America(20.00%),Western Europe(20.00%),South Asia(20.00%),Southeast Asia(15.00%),Mid East(10.00%),South America(5.00%),Eastern Asia(5.00%),Northern Europe(5.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Soldering machine,Precision spot welding machine,Plasma cleaning machine,Glue dispenser,Screw machine

4. why should you buy from us not from other suppliers?

with ultra professional service and skill to provide high performance but competitive price goods, the customer's success is our own success.

5. what services can we provide?

Accepted Delivery Terms: FOB,CIF,EXW,FCA,CPT;

Accepted Payment Currency:USD,EUR,HKD,CNY;

Accepted Payment Type: T/T,PayPal,Cash;

Language Spoken:English,Chinese

We are based in Guangdong, China, start from 2014,sell to North America(20.00%),Western Europe(20.00%),South Asia(20.00%),Southeast Asia(15.00%),Mid East(10.00%),South America(5.00%),Eastern Asia(5.00%),Northern Europe(5.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Soldering machine,Precision spot welding machine,Plasma cleaning machine,Glue dispenser,Screw machine

4. why should you buy from us not from other suppliers?

with ultra professional service and skill to provide high performance but competitive price goods, the customer's success is our own success.

5. what services can we provide?

Accepted Delivery Terms: FOB,CIF,EXW,FCA,CPT;

Accepted Payment Currency:USD,EUR,HKD,CNY;

Accepted Payment Type: T/T,PayPal,Cash;

Language Spoken:English,Chinese

Hot Searches