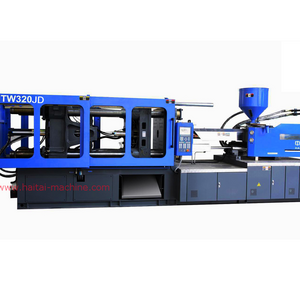

Injection Molding Is Stable,Easy Adjustment

Injection parts with double guide pillar support structure, smooth two cylinder injection device, shoot and two improved nozzle adjustment easy, can be operated by simple adjustment of the nozzle and the mould center. Injection unit 3 different screw diameter in each group, for customers to choose, fully meet the requirements of personalized processing technology.

- Product Details

- {{item.text}}

Quick Details

-

Ejector Force(kN):

-

45 kN

-

Theoretical Shot Volume(cm³):

-

318 cm³

-

Injection Rate (g/s):

-

141 g/s

-

Injection Weight (g):

-

289 g g

-

Screw diameter (mm):

-

45 mm mm

-

Weight (KG):

-

4800

-

Place of Origin:

-

Zhejiang, China

-

Open Stroke(mm):

-

420 mm mm

-

Model Number:

-

HDX168

-

Brand Name:

-

Haida

-

Power (kW):

-

15 kW

-

Machine weight:

-

4.8T

-

Machine dimension(L*W*H):

-

5.2*1.3*2.1m

-

Screw diameter:

-

40/45/48mm

-

SCREW L/D RATIO:

-

22.5/20.3/19

-

Voltage:

-

380V/ 50Hz 3P+N+E (alterable)

-

Heating power:

-

10kW

-

MOULD THICKNESS:

-

180-500mm

-

Ejector Stroke:

-

140mm

-

Ejector force:

-

45kN

-

Opening Stroke:

-

420mm

-

Certification:

-

CE,ISO9001

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

455 mm mm

-

Distance between Tie Bars(Height)(mm):

-

455 mm mm

-

Ejector Stroke(mm):

-

140 mm mm

-

Ejector Force(kN):

-

45 kN

-

Theoretical Shot Volume(cm³):

-

318 cm³

-

Injection Rate (g/s):

-

141 g/s

-

Injection Weight (g):

-

289 g g

-

Screw diameter (mm):

-

45 mm mm

-

Weight (KG):

-

4800

-

Place of Origin:

-

Zhejiang, China

-

Open Stroke(mm):

-

420 mm mm

-

Model Number:

-

HDX168

-

Brand Name:

-

Haida

-

Power (kW):

-

15 kW

-

Machine weight:

-

4.8T

-

Machine dimension(L*W*H):

-

5.2*1.3*2.1m

-

Screw diameter:

-

40/45/48mm

-

SCREW L/D RATIO:

-

22.5/20.3/19

-

Voltage:

-

380V/ 50Hz 3P+N+E (alterable)

-

Heating power:

-

10kW

-

MOULD THICKNESS:

-

180-500mm

-

Ejector Stroke:

-

140mm

-

Ejector force:

-

45kN

-

Opening Stroke:

-

420mm

-

Certification:

-

CE,ISO9001

Product Description

160ton 160t 1680kN Plastic Injection Molding Machine

Broad Scope Of Application

For More Than 95% Of The Injection Molding Products

The Stability Of The Mature And

Reliable

Durable

Running Stability

High Performance To Price Ratio

Concise And Effective

Rapid Flexible

Manipulation Of The Simplified

Simple Maintenance

parameters

|

ITEM

|

|

UNIT

|

DATA

|

|

|

|||

|

Injection Unit

|

Screw Diameter

|

mm

|

40

|

45

|

48

|

|||

|

|

Screw L/D Ratio

|

L/D

|

22.5

|

20.3

|

19

|

|||

|

|

Injection Volume

|

cm

3

|

251

|

318

|

362

|

|||

|

|

Shot Weight

|

g

|

229

|

289

|

329

|

|||

|

|

Injection Pressure

|

Mpa

|

202

|

159

|

140

|

|||

|

Clamping Unit

|

Clamping Force

|

kN

|

1680

|

|

|

|||

|

|

Opening Stroke

|

mm

|

420

|

|

|

|||

|

|

Mould Thickness(Min-Max)

|

mm

|

180-500

|

|

|

|||

|

|

Space Between Tie-Bars

|

mm

|

455×455

|

|

|

|||

|

|

Ejector Force

|

kN

|

45

|

|

|

|||

|

|

Ejector Stroke

|

mm

|

140

|

|

|

|||

|

General

|

Motor Power

|

kW

|

15

|

|

|

|||

|

|

Heater

|

kW

|

10

|

|

|

|||

|

|

Pump Pressure

|

Mpa

|

16

|

|

|

|||

|

|

Machine Dimension

|

m

|

5.2×1.3×2.1

|

|

|

|||

|

|

Machine Weight

|

T

|

4.8

|

|

|

|||

|

|

Mould Orientation Ring Diameter

|

mm

|

Φ125

|

|

|

|||

|

|

Nozzle Radius

|

mm

|

SR15

|

|

|

|||

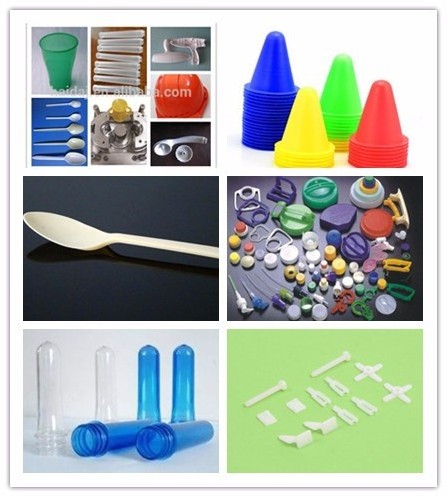

Applications

Detailed Images

Injection System

Clamping Systems

Efficient And Accurate Positioning

Optimization design of oblique line of five fulcrum hyperbolic elbow mold clamping mechanism, power transfer effectively, ensure the process of high speed response. Rapid mold-shut platform but also shorten the molding cycle, improve the production efficiency; Low pressure mold protection system; A variety of hydraulic ejector mode; Can transfer the template support structure; Rod special craft processing, strength and reliable.

Optimization design of oblique line of five fulcrum hyperbolic elbow mold clamping mechanism, power transfer effectively, ensure the process of high speed response. Rapid mold-shut platform but also shorten the molding cycle, improve the production efficiency; Low pressure mold protection system; A variety of hydraulic ejector mode; Can transfer the template support structure; Rod special craft processing, strength and reliable.

Control System

All Monitoring, Full Control

Color LCD display; Abnormal alarm function; Special injection molding machine controller, the double CPU control, control and display CPU are relatively independent, and reliable; Stop button QianHouMen economy; Realtime monitor shows every action operation situation; The system hardware I/O testing function; Special injection molding machine controller; Cylinder temperature deviation corrections; High precision displacement sensor system.

Color LCD display; Abnormal alarm function; Special injection molding machine controller, the double CPU control, control and display CPU are relatively independent, and reliable; Stop button QianHouMen economy; Realtime monitor shows every action operation situation; The system hardware I/O testing function; Special injection molding machine controller; Cylinder temperature deviation corrections; High precision displacement sensor system.

Hydraulic System

Ease Of Maintenance, Compact Structure

Low noise quantitative pump system The oil temperature deviation alarm function Tank level gauge Hydraulic oil cooling unit

Low noise quantitative pump system The oil temperature deviation alarm function Tank level gauge Hydraulic oil cooling unit

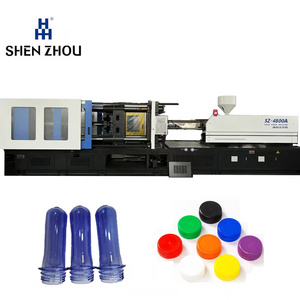

Related Products

HDX78

HDX88

HDX128

Hot Searches