- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

Hot Product 2023

-

Production Capacity:

-

450t/h

-

Power:

-

273

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

CLW

-

Dimension(L*W*H):

-

11950x2500x3800 mm

-

Product name:

-

Asphalt Paver

-

Name:

-

Chipping Spreader

-

Application:

-

Asphalt Paving

-

Key words:

-

Chip Seal Truck

-

Type:

-

Bitumen Spreader

-

Color:

-

Customer Requirements

-

Model:

-

Hydraulic Paver

-

Engine:

-

WD615.47

-

Brand:

-

Sinotruck howo

-

Driving type:

-

8x4

Quick Details

-

Max. Paving Thickness:

-

200-300mm

-

Weight:

-

31000 kg

-

Engine Brand:

-

WEICHAI

-

Marketing Type:

-

Hot Product 2023

-

Production Capacity:

-

450t/h

-

Power:

-

273

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

CLW

-

Dimension(L*W*H):

-

11950x2500x3800 mm

-

Product name:

-

Asphalt Paver

-

Name:

-

Chipping Spreader

-

Application:

-

Asphalt Paving

-

Key words:

-

Chip Seal Truck

-

Type:

-

Bitumen Spreader

-

Color:

-

Customer Requirements

-

Model:

-

Hydraulic Paver

-

Engine:

-

WD615.47

-

Brand:

-

Sinotruck howo

-

Driving type:

-

8x4

Hi, This is Larry from Chengli Special Automobile Co.,Ltd.

We are manufacturer of all kinds of special trucks and pressure vessel(lpg tanks) since the year 2004.

I am also working in this field more than 5 years, feel free to contact me for the quick response by

24 hours telphone number(whatsapp and wechat) 0086 15071226018

Chengli 8x4 sinotruck brand 8m3 asphalt tank and 12m3 gravel tank synchronous chipsealer

|

ITEM |

UNIT |

PARAMETER |

|

|

Vehicle |

|

Howo Synchronous chipsealer |

|

|

Overall dimensions |

mm |

11950x2500x3800 |

|

|

Asphalt tank dimention |

2500x2400x2020 /ellipse |

||

|

Insulating layer |

80 |

||

|

Asphalt tank capacity |

m3 |

8 |

|

|

Gravel tank capacity |

12 |

||

|

GVW |

kg |

Appro×42870 |

|

|

Curb weight |

Appro×20870 |

||

|

Payload |

Appro×22000 |

||

|

Approach/departure angle |

° |

16/14 |

|

|

Front and middle axle |

HF9 |

Rear axle |

HC16 |

|

Drive system |

8x4 |

Steel |

Power, sino |

|

Tire specification |

12.00-20 16PR |

Number of axles |

4 |

|

Manufacturer |

China National Heavy Duty Truck Group Co ., Ltd |

||

|

Model |

WD615.47 |

||

|

Emission/kw |

9726ml/273Kw, 371hp |

||

|

Gear box |

10F&2R |

||

|

Asphalt tank |

Stainless steel scrub, with Insulating layer |

||

|

Spray medium |

Hot asphalt, emulsified asphalt and residual oil |

||

Synchronous gravel seal is to use a special equipment, namely synchronous gravel sealer, to spread the gravel and bonding materials (modified asphalt or modified emulsified asphalt) on the road surface, and form a single layer of asphalt through natural driving. The gravel wear layer, which is mainly used as a pavement surface layer, and can also be used for low-grade road surface layers. The biggest advantage of the synchronous gravel sealing technology is that the bonding material and the stone material are simultaneously laid, and the high-temperature bonding material sprayed on the road surface can be combined with the gravel immediately without cooling, thereby ensuring the bonding material and the stone material. A strong bond between the two.

Synchronous gravel seal has good anti-sliding performance and anti-seepage performance, can effectively cure road poor oil, falling particles, slight cracks, rutting, subsidence and other diseases, mainly used for preventive maintenance and corrective maintenance of roads. As well as improving the anti-slip performance of high-grade roads, this new maintenance technology can be used on both expressways and ordinary roads. More than 95% of roads in France and Europe use synchronous gravel seals for pavement maintenance. In addition, the synchronous gravel seal can also be used as a low-grade road surface layer. In France, more than 40% of the roads directly use the gravel seal as the road surface, and the current use effect is good. Therefore, in the case of insufficient funds for road construction, the use of low-cost synchronous gravel seals as low-grade road pavement is undoubtedly an effective measure to improve the road pavement rate.

Synchronous gravel seal refers to the simultaneous spraying of the asphalt binder and the spreading of the aggregate by the synchronous gravel sealer, so that the asphalt binder and the aggregate have the most complete contact to achieve the maximum between them. The degree of bonding.

Compared with the ordinary gravel seal, the synchronous gravel seal shortens the time interval between the spray adhesive and the spread aggregate, so that the aggregate particles can be better implanted into the binder to obtain more Covering area. It is easier to ensure a stable proportional relationship between the binder and the stone chips, improve work productivity, reduce mechanical configuration, and reduce construction costs.

After the asphalt pavement is sealed by synchronous gravel, it has better anti-skid and anti-seepage performance, and can effectively cure the road surface such as poor oil, falling particles, slight cracks, rutting and subsidence. This technology can be used on both high-grade and ordinary roads.

Synchronous gravel seal technology has excellent water resistance, high slip resistance, and good performance in dealing with pavement cracks, ensuring 7-10 years of road maintenance performance without loss of aggregate.

Synchronous gravel sealer is used for: the lower sealing layer of the road pavement, the construction of the upper seal layer, the construction of the wear layer of the new and old pavement, the layering method of the asphalt pavement, and the sprinkling (sprinkling) of the asphalt gravel under special circumstances.

1, manual/automatic control enhanced additionally and width, each nozzle can be individually controlled, determinant nozzle free combination, so as to realize arbitrary adjust the width of spray. In the cab for distributing control or the rear of the platform.

2, the automatic control system can measure the speed of the car and according to the input amount of spill cloth and spraying width and asphalt type, automatic calculation of asphalt pump revolution to adjust the asphalt pump pump automatically by the system.

3, vehicular rapid heating system (10-15 ºC / h), can improve the heating efficiency and reduce the auxiliary time of construction, ensure that makes temperature;

4, blunt the nozzle of the system residual asphalt by diesel with high pressure air nozzle can be blown out, prevent asphalt to freeze in the nozzle, improve the service life of the nozzle.

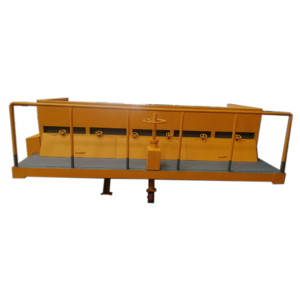

Major parts of the chip sealer

Chip sealer 4x2, 6x4 and 8x4

Customer train and inspection

Chip sealer export cases 6x4 to Africa

Chip sealer export cases 8x4 to Africa

Performance of chip sealer

Our Factory

Products Display

Cooperative Partner

Qualification Certificate

Packaging & Shipping

Cooperative Brand

FAQ

1.You are factory or trading Company?

Yes, we are oversea sales department of Chengli automobile. And you are always welcomed to visit our factory.

2.Could your company modify the standard product depends on my request?

Yes. Our company is specialized in researching and designing various of special purpose vehicle and spare parts. We can provide any product according to your demand.

3. Could your company totally customize products for me?

We can provide the customized-designing product meeting with any of your demand.

4. Could you provide certification that we need?

We can provide various certifications associate with trailer and truck. Such as DOT, ADR, SASO and so on.

5. How long could we receive our goods?

It depends on the product that you have ordered. If the goods are prepared, we will deliver your goods as soon as possible.

6. How about the after-sale service?

We can provide you the technical support to guide you repaire your product. And we will also send original spare parts free of charge by air. If you have special need, we can let our engineer to help you in person

Contact us