- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

2960*1320*1550

-

Weight:

-

2350 KG

-

Warranty:

-

1 Year

-

Cylinder size:

-

400*600mm

-

Midfield strong magnetic field:

-

250-400 mT

-

Item:

-

Beneficiation Plant

-

Cylinder speed:

-

45 r/min

-

Product name:

-

Nice Quality laboratory magnetic separator

-

Application:

-

coal preparation plant/mine

-

Color:

-

Customers' Requirements

-

Installation:

-

Technical Guidance

-

After sale service:

-

Engineer Overseas Service

-

Local Service Location:

-

Viet Nam

-

Certification:

-

ISO9001

Quick Details

-

Production Capacity:

-

2-3 t/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GUOTE

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

2960*1320*1550

-

Weight:

-

2350 KG

-

Warranty:

-

1 Year

-

Cylinder size:

-

400*600mm

-

Midfield strong magnetic field:

-

250-400 mT

-

Item:

-

Beneficiation Plant

-

Cylinder speed:

-

45 r/min

-

Product name:

-

Nice Quality laboratory magnetic separator

-

Application:

-

coal preparation plant/mine

-

Color:

-

Customers' Requirements

-

Installation:

-

Technical Guidance

-

After sale service:

-

Engineer Overseas Service

-

Local Service Location:

-

Viet Nam

-

Certification:

-

ISO9001

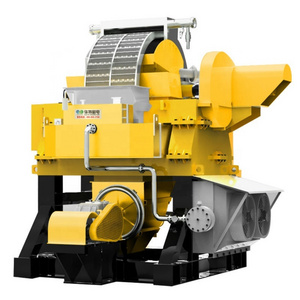

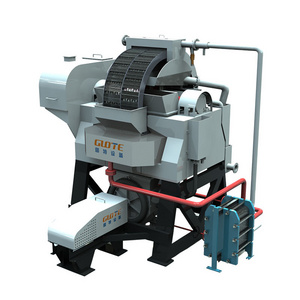

1.Applicable Scope

This product(Guote GTLH) is applicable to 1.2 mm (- 200Mesh 30-100%) of fine non-metallic mineral, such as quartz, feldspar, nepheline ore, kaolin, iron removal purification. Can also be used for red iron ore (hematite, limonite and siderite, etc.), manganese ore, ilmenite, black tungsten, a variety of weak magnetic ore wet separation and black and white tungsten separation, black tungsten and tin separation.(For details, please contact me:Annie Chang,Mob:0086-18678029069(whatsapp),E-mail: Annieflower.chang dot sdguote.com)

2. Work Principle:

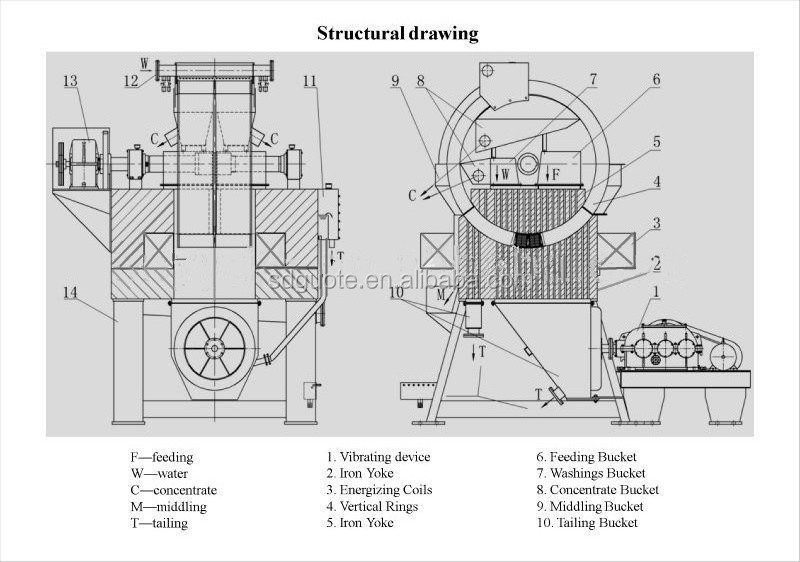

Weifang Guote High Intensity Wet Vertical Ring Magnetic Separator ,Magnetic yoke fixed on the machine frame, which generate the strong magnetic field together with exciting coil. Rotary ring is in the clockwise drived by the rotary device, and goes through the magnetic field slowly. There are many separation boxes on the outer circle of the rotary ring , there is the multi-layer magnetic medium which is made of magnetic material inside the separation box. When the rotary ring goes through the magnetic filed, it would be magnetized, and formed the high gradient magnetic field. In the mineral processing, the mine slurry goes into the rotary ring along with the gap of the magnetic pole, and the magnetic particle would be attracted in the magnetic medium surface, revolving to the non-magnetic area. The magnetic particle would be put into the fine tank, and the nonmagnetic material goes into the tailing tank along the lower magnetic yoke gap.

3. Technical Drawing

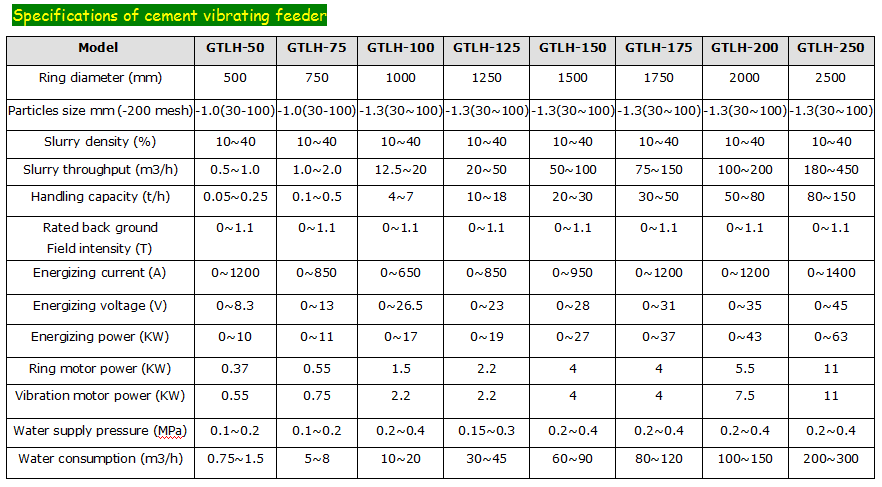

4.Technical Parameter

5. Technical features

1. Vertical Ring Rotation & Pulsating Beneficiation

2. High Frequency Vibration Mechanism

3. Wide Range of Feed Particle Size

4. Multi-Gradient Matrixes & Liquid Level Control System.These technologies improve the grade of magnetic concentrate and recovery.

5. Frequency Conversion Step-less Adjustment for Rotary Speed & Vibrating Frequency.

6. No Stepper Phenomenon of Rotary Rings(For details, please contact me:Annie Chang,Mob:0086-18678029069(whatsapp),E-mail: Annieflower.chang dot sdguote.com)

6. Product Details and Customer Case

7. Application field

1. Updating Ferrous Metals: Martite, Hematite, Siderite, Chromite, Ilmenite, Manganese, Etc.

2. Separating Non-Ferrous Metals: Wolframite and Quartz, Pyrrhotite and Cassiterite, Wolframite and Cassiterite, Limonite Purifying, Scheelite, Wolframite and Garnet, Etc.

3. Recovering Rare Earth: Tantalum and Niobium, Lepidomelane, Monazite, Etc.

4. Brightening Non Metals: Quartz, Feldspar And Kaolin for Ceramics, Sillimanite, Cassiterite, Andalusite, Kyanite for Refractory, and Separating Impurities From Hornblende, Mica, Tourmaline, Garnet, Etc.

Weifang Guote GTLH Series high gradient magnetic separator is a new product developed independently by GUOTE. It combines the characteristics of international advanced high intensity magnetic separators, which is so far the high intensity magnetic separator of best performance and most advanced technology. This product utilizes vertical ring rotation, pulsating beneficiation and high frequency vibrator, and it has no magnetic medium jam problem in flat ring high intensity magnetic separator and flat ring high gradient magnetic separator.It has the advantages of large beneficiation ratio, high security and convenient operation etc. This product realizes both high beneficiation ratio and high recycle ratio in separating weak magnetic minerals.(For details, please contact me:Annie Chang,Mob:0086-18678029069(whatsapp),E-mail: Annieflower.chang dot sdguote.com)

Wet Magnetic Separators / Mineral Separator Machine

1.Introduction of CTB wet magnetic separator

Series CTB wet magnetic separator is usally used for sorting the fine-grained magnetic minerals, or removing magnetic minerals from non-magnetic minerals. Its composite magnetic system consists of high performance rare earth permanent magnet (main magnetic source) and ferrite permanent magnet. With a deep magnetic field, the machine can make a continuous row of ore feed and discharge. It also has enough working clearance and high processing capacities(For details, please contact me:Annie Chang,Mob:0086-18678029069(whatsapp),E-mail: Annieflower.chang dot sdguote.com).

Applicable scope:

The permanent magnetic drum separator are used in mines and coal separating factories to separate the wet fine magnetic substances or remove the magnetic substances from the non-magnetic materials

2.Working principal of CTB wet magnetic separator

When the ore pulp goes into the separation area of the wet drum magnetic separator, as a result of different magnetic susceptibilities of a variety of minerals, under the magnetic force, the magnetic minerals are absorbed to the surface of drum, and are brought to the discharge area for ore concentrate along with the rotation of drum, then after leaving the magnetic system, the magnetic materials are flushed to ore concentrate box by the flushing water; Weak magnetic and non-magnetic minerals can not be absorbed and will flow to the discharge pipe for tailings.

4.Advantage of wet magnetic separator

♦ High magnetic field intensity

♦ Magnetic field depth, uneasy demagnetization

♦ High efficiency

♦ Strong adaptability of production fluctuation

5.Technical parameter of the machine

| Model |

Capacity (t/h) |

Magnetic intensity (oe) |

Power (kw) |

Weight (wt) |

|

CTB600*900 |

8-15 |

1450 |

1.1 |

0.91 |

|

CTB600*1800 |

15-25 |

1500 |

2.2 |

1.34 |

|

CTB750*1200 |

25-30 |

1550 |

2.8 |

1.49 |

|

CTB750*1800 |

30-45 |

1550 |

3 |

2.05 |

|

CTB900*1800 |

35-60 |

1550 |

4 |

3 |

|

CTB1050*2400 |

55-90 |

1550 |

5.5 |

5 |

|

CTB1200*3000 |

80-150 |

1550 |

7.5 |

7.8 |

|

CTB1500*3000 |

120-200 |

1550 |

11 |

9.6 |

6. Technical Characteristics:

The separators have three types of tanks :half countercurrent tank(CTB),direct flow tank(CTS) and countercurrent tank(CTN),which are used according to different granular and technological requirements.

The features of our products are :optimized computer design ,rational magnetic circuit, strong magnetic coercive force and high-remanence permanent magnetic which can keep the magnet performance in a long period and safeguard the long -term interest of the customer, the whole structure is reliable. (For details, please contact me:Annie Chang,Mob:0086-18678029069(whatsapp),E-mail: Annieflower.chang dot sdguote.com)

Models and parameters:

7.pictures about wet magnetic separator

OEM Service

We could make whole production line or single equipment following different clients requirements.

For whole process as below:

- Firstly Please offer detailed technical drawing in CAD including whole detailed requirements.

- Secondly we will offer different technical proposals follwing offered drawings with requirements for clients.

- Thridly make decision for which proposal and confirm it.

- At last manufacture whole equipments following techncial proposal and holding test in warehouse.

- Finally finished equipment/prodcution line and offered service as turn-key-project.

For details, please contact me:

Annie Chang

Mob:0086-18678029069(whatsapp)

E-mail: Annieflower.chang dot sdguote.com

Weifang GUOTE Mine Equipment co.ltd. is professional and modern enterprise including research and development, engineering design, production and installation, debugging services , automatic control equipment, non-metallic mineral production line test, design, consultation and the complete line of delivery.The scope of services related to mining, metallurgy, electric power, coal, glass, paper, chemical building materials, refractory materials, tiles,food, cement ,etc.Our product sell well in more than thirty provinces, autonomous regi on. (For details, please contact me:Annie Chang,Mob:0086-18678029069(wechat/whatsapp),E-mail: Annieflower.chang dot sdguote.com)

Our product have electromagnetic, permanent magnetic separator, dry wet magnetic separator,electromagnetic vibration feeder, quartz sand making machine, air classifier, dust collector, water separator, washing machine, flotation machine,metal detector, screw conveyor, timing quantitative feeding,weigher and centralized control system, etc.

Facing the new opportunities and challenges, the company in line with the spirit of "honesty-oriented, mutual benefit, cooperation and innovation" , dedicated to providing “dependable,simple and efficient” products and services to customers, make enterprises become domestic advanced mining equipment manufacturer.

Our company is willing to work together with people from all walks of life for a better future.

Contact Information-

Annie Chang

Mob: +86 18678029069

(WhatsApp/wechat)

Skype:anna1983cyj ,QQ:896247401

Email:annieflower.chang at sdguote.com

website: https://sdguote.cnen.alibaba.com/

If you have any questions, pls don't hesitated to contacting me anytime.