1. It complies with GMP, cGMP and FDA requirements to meet the production needs of aseptic APIs.

2. The complete isolation of power and production areas is suitable for occasions with higher cleanliness requirements to avoid contamination of products.

3. The shell can be opened completely, so that the entire inside of the centrifuge can be observed, wiped and cleaned by touch.

4. It can realize SIP( Sterilization In Place)and CIP(Clean in place), which can effectively wash the internal parts of the centrifuge that are not easy to clean and avoid cross-contamination.

5. Optional steam sterilization kit is available for steam sterilization disinfection.

6. Equipped with a unique gas back flushing device, it can effectively remove the residual filter cake layer.

7. Optional residual filter cake automatic removal device (national patent).

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

15000

-

Dimension(L*W*H):

-

3439*2316* 2428 mm

-

Applicable Industries:

-

Food industry, Intermediates for apis

-

Product name:

-

Saideli GKC series oil horizontal separator with PLC control

-

Brand:

-

Saideli

-

Loading capacity:

-

230 kg

-

Certificate:

-

ISO/CE

-

Main control:

-

PLC control

-

MOC:

-

Stainless steel, duplex steel, TA2, Hastelloy etc

-

Operation:

-

Automatic Continuous Operate

-

Motor start control:

-

Frequency control

-

Patent:

-

Patented product

Quick Details

-

Place of Origin:

-

Jiangsu China

-

Marketing Type:

-

New Product 2024

-

Brand Name:

-

Saideli

-

Weight:

-

15000

-

Dimension(L*W*H):

-

3439*2316* 2428 mm

-

Applicable Industries:

-

Food industry, Intermediates for apis

-

Product name:

-

Saideli GKC series oil horizontal separator with PLC control

-

Brand:

-

Saideli

-

Loading capacity:

-

230 kg

-

Certificate:

-

ISO/CE

-

Main control:

-

PLC control

-

MOC:

-

Stainless steel, duplex steel, TA2, Hastelloy etc

-

Operation:

-

Automatic Continuous Operate

-

Motor start control:

-

Frequency control

-

Patent:

-

Patented product

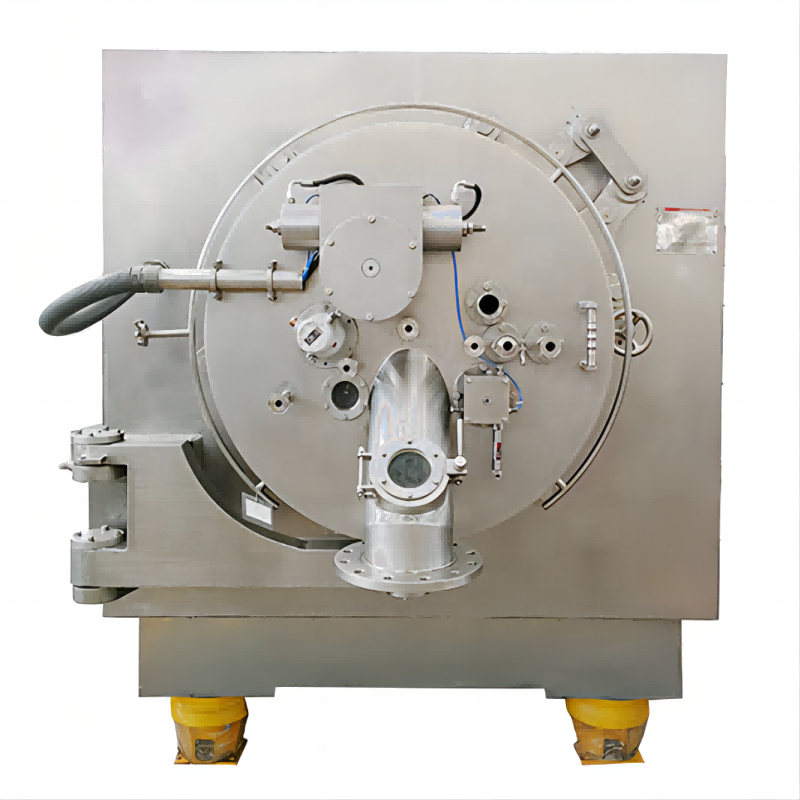

Products Description

GKC series automatic horizontal scraper centrifuge

GKC series clean-type automatic horizontal scraper centrifuge is installed through the wall, which can separate the power area from the production area, used in the intermediates for API industry with high cleanliness requirements. This type of centrifuge allows the entire shell to be opened for easy inspection and cleaning.

Main Feature

Product Parameters

|

Item/Model

|

GKC-600

|

GKC-800

|

GKC-1000

|

GKC-1050

|

GKC-1250

|

GKC-1350

|

GKC-1600

|

|

Drum diameter (mm)

|

600

|

800

|

1000

|

1050

|

1250

|

1350

|

1600

|

|

Drum height(mm)

|

315

|

400

|

500

|

500

|

630

|

680

|

800

|

|

Drum volume(L)

|

41

|

100

|

180

|

210

|

335

|

500

|

700

|

|

Loading capacity(Kg)

|

53

|

130

|

230

|

270

|

430

|

650

|

900

|

|

Max. speed(rpm)

|

2400

|

1500/1800

|

1400

|

1400/1700

|

1200

|

1200

|

950

|

|

Max. Separating factor (N)

|

1931

|

1007/1448

|

1096

|

1150/1696

|

1006

|

1086

|

808

|

|

Main Motor power (Kw)

|

18.5

|

30

|

37

|

37

|

55

|

55

|

90

|

|

Size with shock absorber(mm)

|

2016*1410*1480

|

2620*2000*2070

|

3439*2316*2428

|

3439*2316*2428

|

3700*2500*2700

|

3880*2600*2700

|

4823*3400*3355

|

|

Weight including platform(kg)

|

4000

|

9800

|

15000

|

16000

|

18000

|

22000

|

33000

|

Working principle

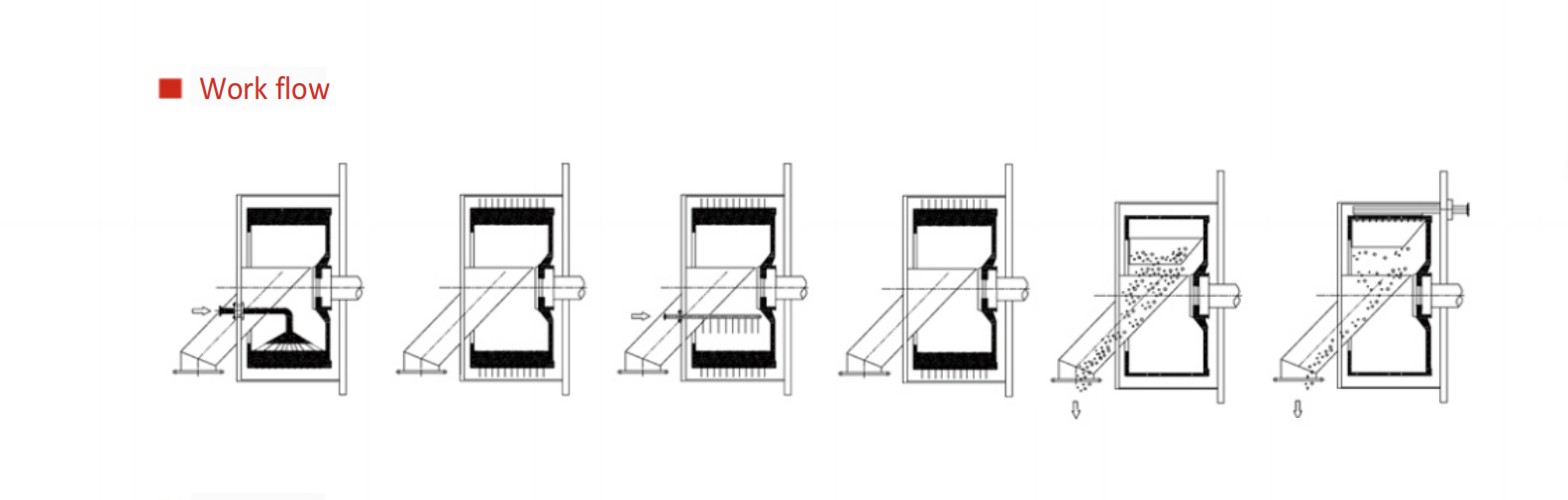

The main machine is filled with nitrogen or other inert gas, when a preset target is reached, the main machine starts up and automatically increases the speed. When the drum speed reaches the feeding speed, the feed valve automatically opens, while the material level detector also begins to work, when the material layer reaches a certain thickness, that is, when it encounters the material level detection plate, the feed valve automatically closes and stops feeding. Under the action of centrifugal force, most of the liquid in the suspension is thrown out through the filter cloth (screen) and the small holes on the wall of the drum, and then flows to the mother liquor tank through the radial discharge port of machine shell(the primary filtration stage). After the material is dried for a certain period of time, it will be washed. At this time, according to the requirements of the process, the

centrifuge will automatically decelerate to the washing speed, and the washing valve will be opened automatically, and when the washing liquid reaches a certain thickness, the washing valve will be closed automatically, and the centrifuge will automatically

increase the speed to high speed for further drying (fine filtration).

After running for a certain period of time, the material is fully dry, it’s time for discharging. The centrifuge automatically decelerates to the set speed, the discharge valve opens, the discharge cylinder starts to work, the scraper automatically rotates to rise, the solid material is scraped down into the hopper fitted with a spiral discharge device. The spiral discharge device continuously pushes out the material and discharges it out of the machine through the valve.When the scraper rises to a certain distance away from the filter cloth, the block on the scraper device is close to the proximity switch, the scraper stops rising and stays for a period of time (about 15s), and then quickly returns to the next cycle.

centrifuge will automatically decelerate to the washing speed, and the washing valve will be opened automatically, and when the washing liquid reaches a certain thickness, the washing valve will be closed automatically, and the centrifuge will automatically

increase the speed to high speed for further drying (fine filtration).

After running for a certain period of time, the material is fully dry, it’s time for discharging. The centrifuge automatically decelerates to the set speed, the discharge valve opens, the discharge cylinder starts to work, the scraper automatically rotates to rise, the solid material is scraped down into the hopper fitted with a spiral discharge device. The spiral discharge device continuously pushes out the material and discharges it out of the machine through the valve.When the scraper rises to a certain distance away from the filter cloth, the block on the scraper device is close to the proximity switch, the scraper stops rising and stays for a period of time (about 15s), and then quickly returns to the next cycle.

Certifications

Workshop

Customer Photos

FAQ

Q1: Do you have OEM service? Do you supply the parts?

A: Yes, we do, as long as you provide us your drawing and detailed requirements.

Q2: How can we easily find out the most fit centrifuges?

A: We have experienced engineer team to help you make the model selection, as long as you provide us the detailed processing material characteristics.

Q3. Will you provide installation services?

A: If you need, we can arrange professional technicians and engineers to install and debug on site.

Q4. What is your advantage compared with your competitors?

A: Quality and experience. We are the largest centrifuge supplier in the world, our designs and structures are similar to world leader Alfa Laval, Westfaliar, Flottweg etc.

Q5. Where is your factory located?

A:Our factory is located in Jingjiang, which nears Shanghai port and Ningbo Port about 2 hours.

Hot Searches