- Product Details

- {{item.text}}

Quick Details

-

Chemical Desrciption:

-

Micronized PTFE

-

Apperance:

-

White Powder

-

Features & Benefits:

-

Excellent abrasion, scratch resistance and slippery property

-

Keywords:

-

Polymer Based Additives for Engineering Plastics

-

Shelf life:

-

2 Years

Quick Details

-

CAS No.:

-

9002-84-0

-

Purity:

-

100%

-

Place of Origin:

-

Jiangsu, China

-

Chemical Desrciption:

-

Micronized PTFE

-

Apperance:

-

White Powder

-

Features & Benefits:

-

Excellent abrasion, scratch resistance and slippery property

-

Keywords:

-

Polymer Based Additives for Engineering Plastics

-

Shelf life:

-

2 Years

Polymer Based Additives for Engineering Plastics

The produces are very fine PTFE powder, have very low coefficient of friction when added in coating and ink.The products have excellent mar and abrasion resistance ,slip. The products are heat resistant, chemical resistant, insoluble and can be used with micronized pe wax for cooperant effect. Additive for improveing the slip and scratch resistance of can coatings, coil coatings, wood lacquers, and powder coatings.

PTFE-0107

Micronized PTFE Wax

Chemical Composition

PTFE

Technical Parameters

|

Nature of the Product |

PTFE-010 7 |

|

|

Appearance |

|

White Powder |

|

Particle Size μm |

|

|

|

|

Dv50 |

5 |

|

|

Dv90 |

10 |

|

Melting Point ℃ |

|

320 |

Characteristics and Purposes

Ø The micronized wax PTFE-010 7 has very good heat resistance, lubricity, dispersity, and storage stability.

Ø Can make the products with very low friction coefficient when added into coatings and inks, improve the abrasion resistance,scratch resistance and lubricity of the coating.

Ø With the addition level at 0.1%~3%, can obviously improve the lubricity of the inks, improve the abrasion resistance of the finished products, avoid paper bonding.

Ø Be used in powder coating, the micronized PTFE wax provides a distinct performance on scratch resistance.

Addition level and Processing instructions

Ø In a variety of systems, the addition amount of micronized wax is generally between 0.5 to 3%.

Ø Usually by way of a direct high-speed stirring, it can disperse in solvent-based coatings and inks.

Ø It can be added by using a variety of grinding machines, and high-shear dispersing device. Must pay attention to the control of temperature.

Ø Can make a wax pulp with the wax concentration at 20-30% by pre-dispersing treatment, add it into the systems when needed, by which can reduce the dispersion time.

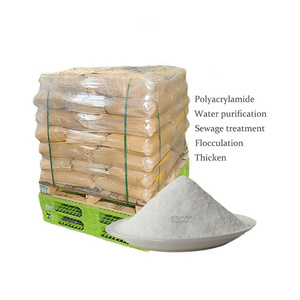

Paper-plastic bag, net weight: 20 kg / bag, 400kg/pallet, 8000kg/20GP;

Delivery:3-7days after payment received;

Hazards

The product is non-dangerous and does not require a hazard warning label according CLP regulation.

For further information please refer to the Material Safety Data Sheet.

Contact Us

Please

contact us

for safety and regulatory details or the Material Safety Data Sheet (MSDS).