- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/440V 50HZ/60HZ, 220V/380V/415V/440V/480V etc

-

Power:

-

2.2-65kw

-

Weight:

-

400 KG

-

Dimension(L*W*H):

-

755*520*935

-

Application:

-

Milk Industry

-

Material:

-

Stainless Steel 304 /316

-

Usage:

-

Milk,beverage,juice,yogurt etc

-

Function:

-

Homogenzing

-

Work pressure:

-

25/40/60Mpa

-

Size:

-

755 X 520 X 935mm

-

Motor Power:

-

2.2kw

-

Certificate:

-

CE ISO9001

-

After Warranty Service:

-

Video technical support

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

Sangtians

-

Model Number:

-

ST-HPL-1

-

Voltage:

-

220V/380V/440V 50HZ/60HZ, 220V/380V/415V/440V/480V etc

-

Power:

-

2.2-65kw

-

Weight:

-

400 KG

-

Dimension(L*W*H):

-

755*520*935

-

Application:

-

Milk Industry

-

Material:

-

Stainless Steel 304 /316

-

Usage:

-

Milk,beverage,juice,yogurt etc

-

Function:

-

Homogenzing

-

Work pressure:

-

25/40/60Mpa

-

Size:

-

755 X 520 X 935mm

-

Motor Power:

-

2.2kw

-

Certificate:

-

CE ISO9001

-

After Warranty Service:

-

Video technical support

Product Description

The high-pressure homogenizer is a device for homogenizing / emulsifying liquid materials

(liquid-liquid phase or liquid-solid phase)

with

a viscosity lower than 0.2Pa.s and a temperature lower than 80 ℃.

When the equipment is working, the processed material is sent to the homogenization valve

through the three-piston reciprocating pump in a high-pressure form

, so that the material flows through the small gap between the valve disc and the valve seat at the moment is subjected to the combined force of turbulence, cavity, shear and other , to achieve the purpose of homogenization and emulsification.

The emulsification average fineness is

below 1um, and the solid dispersion particle size is below 2um

on average.

Advantage:

1. The whole machine is covered

with a stainless steel shell

, and the appearance is

smooth and exquisite, safe and hygienic.

2. Adopt helical gear l

ow-speed transmission, low noise, stable operation and reliable performance.

3. The transmission part adopts

splash type and unique oil delivery method

to ensure the lubrication needs of each part.

4. The

double-sided design of the valve seat

can double the service life.

5. Homogenizing valve, one-way valve and plunger are made of alloy steel, which has the characteristics of

wear resistance, impact resistance and long service life.

6. The processed product is

fine and uniform

,

generally below 1 ~ 2um.

7. The processed product has

good stability and long shelf life.

8. The processed food and medicine can increase the absorption.

The finer the food size, the easier it is absorbed by the human body.

When the

particle size reaches

0.1um, it can be directly absorbed by intravenous injection without gastrointestinal tract.

9. The processed materials can

increase the viscosity and concentration

. (For example, if the concentration of soy milk is increased, the volume of ice cream will be expanded after treatment, and the viscosity will be increased. This will not only save materials, but also increase the production volume of the product)

Application

High-pressure homogenizers are widely used in

the fine processing and ultra-fine crushing of thousands of products in dairy products, soy products, fruit juice beverages, health foods, fine chemicals, daily chemical industry, pharmaceutical industry, papermaking, textile, biochemical engineering and other industries.

In particular, the problems of easy layering and easy precipitation that are difficult to solve for a long time in formula milk, protein drinks, and juice drinks can be solved. It has been successfully applied in the development of new fine chemical products such as

nano-scale pigments, paints and dyes

.

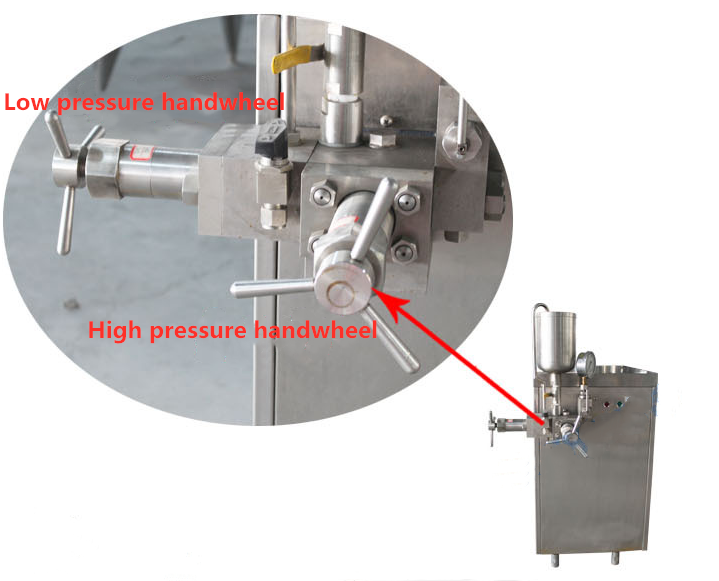

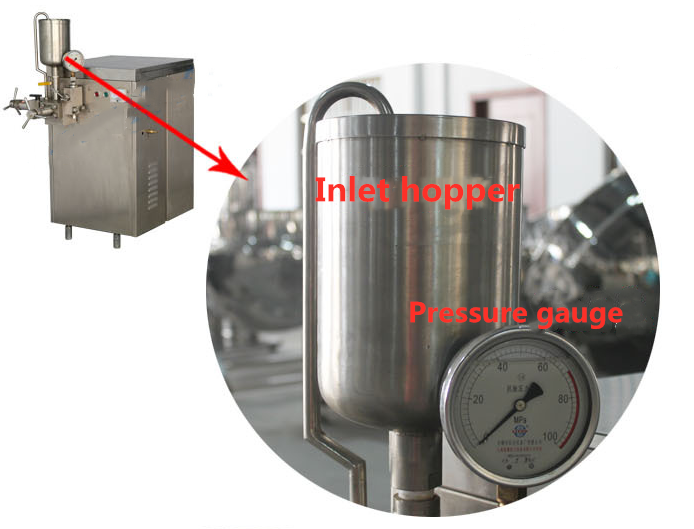

Images of Details

Specification

Selection tips:

1. The above parameter tables are all

production high-pressure homogenizers.

If you need to test, please consult to our sale manager for laboratory high-pressure homogenizer.

2. For the above parameters, the

standard model produced

by our company, if you have

different technical requirements

, Pls contact us kindly.

How to choose:

1. First, select the

required pressure

according to the process requirements and the desired effect

2. According to the

daily output demand

and

the capacity of other equipment

, determine the

hourly output

.

Why choose us

1. The company has sales department, engineering department and after-sales department, we all serve you;

2. What we fight is not the price, but the quality and friendly service;

3. Our salesmen and engineers will patiently listen to your requirements and the effects you want to achieve, tailoring your materials;

4. Our after-sales colleagues will serve you from the time you place the order to the actual production;5. Rich industry experience;

Packing & Delivery

Company Profie

Project layout

Hot Searches