- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

OEM-129

-

Material:

-

ABS,PP,PVC,POM,PA6,PA66,PA66+30%GF

-

Product Name:

-

ABS/PP/PE/PC/PA66/POM Injection Molded Custom Plastic Products

-

Drawing Format:

-

2D/(PDF/CAD)3D(IGES/STEP)

-

Color:

-

Customer's Request

-

Size:

-

According to customer's drawing

-

Application:

-

Industrial

-

Surface treatment:

-

Smooth,Matte,Texture,Electroplate

-

Logo:

-

Screen printing or made in Mold

-

Processing Technic:

-

CNC machining,injection molding & extrusion

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Hebei,China

-

Brand Name:

-

SWKS

-

Model Number:

-

OEM-129

-

Material:

-

ABS,PP,PVC,POM,PA6,PA66,PA66+30%GF

-

Product Name:

-

ABS/PP/PE/PC/PA66/POM Injection Molded Custom Plastic Products

-

Drawing Format:

-

2D/(PDF/CAD)3D(IGES/STEP)

-

Color:

-

Customer's Request

-

Size:

-

According to customer's drawing

-

Application:

-

Industrial

-

Surface treatment:

-

Smooth,Matte,Texture,Electroplate

-

Logo:

-

Screen printing or made in Mold

-

Processing Technic:

-

CNC machining,injection molding & extrusion

Product Description

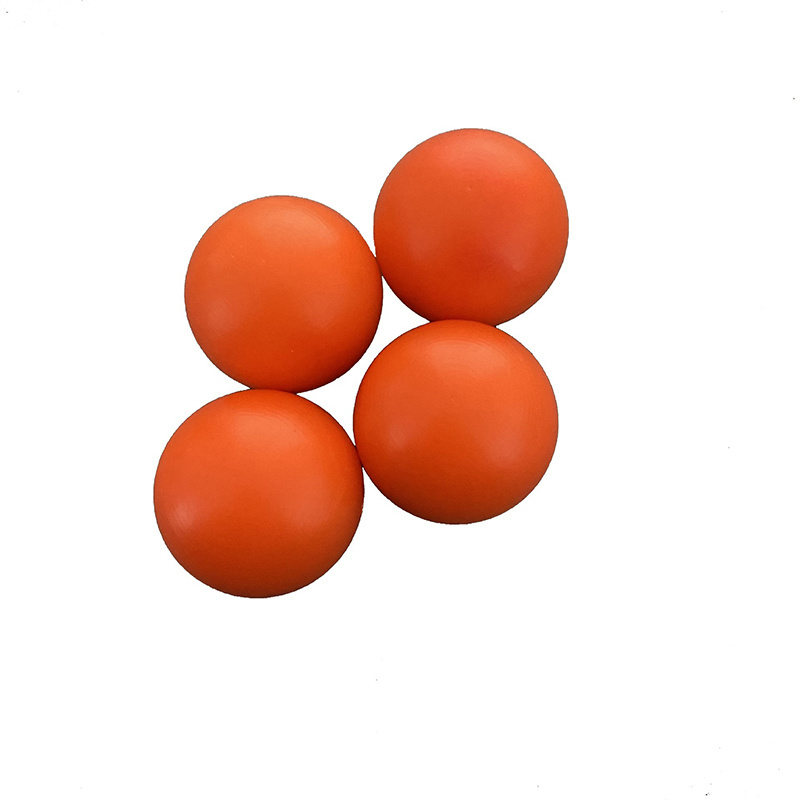

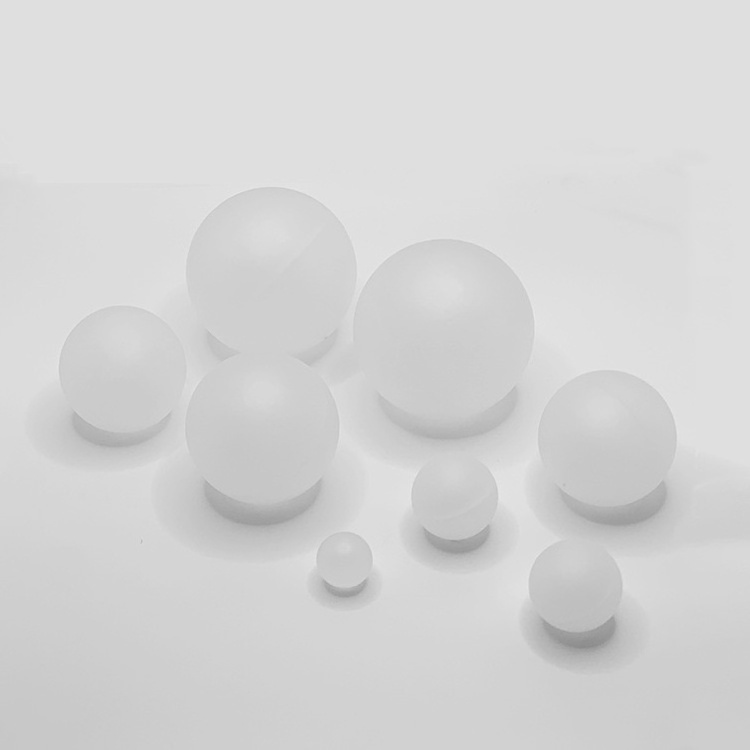

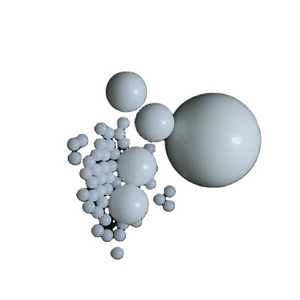

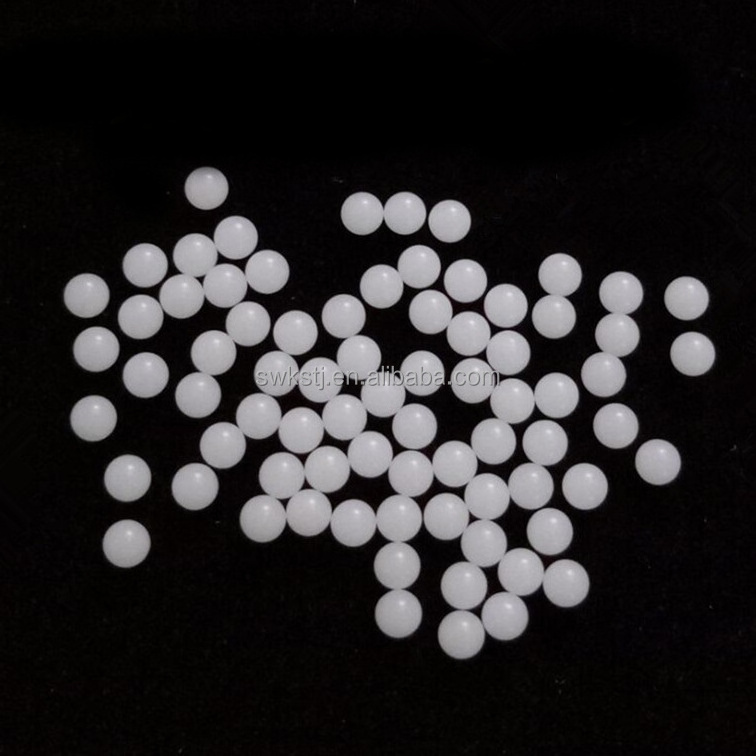

10mm/30mm POM Plastic Ball Solid Large Plastic Bead Plastic Balls

Solid plastic ball injection process

1. Raw material preparation: Select the appropriate raw materials according to the material type of the required solid plastic ball.

2. Injection molding machine setting: Set the injection temperature, injection speed, pressure holding time and other parameters of the injection molding machine according to the characteristics of the selected material.

3. Injection mold setup: Install the mold on the injection molding machine, and carry out necessary cleaning and maintenance.

4. Operation process: Open the injection molding machine, install the mold, add the raw materials into the hopper of the injection molding machine, and perform primary heating.

5. Injection molding process: the raw material is fed into the screw of the injection molding machine after primary heating, and then injected into the mold under the pressure of the injection molding machine to form a solid plastic ball.

6. Cooling treatment: After finding that the plastic ball has been formed, the mold can be opened, the ball is removed from the mold, and the cooling treatment is carried out to treat the problems of sintering and defects on the surface of the ball.

|

Product

Name

|

PP plastic ball

Polypropylene |

POM plastic ball

Delrin |

PA66 Plastic ball

Nylon |

PTFE plastic ball Polytetrafluoro ethylene

|

|

Size

|

3mm-100mm

|

1mm-100mm

|

4.763mm-100mm

|

1mm-80mm

|

|

Material

|

Polypropylene balls

|

Delrin, POM balls

|

Nylon Balls

|

Teflon Balls-PTFE

|

|

Grade

|

G0-G3

(±0.01-0.05mm) |

G0-G3

(±0.01-0.05mm) |

G0-G3

(±0.01-0.05mm) |

G0-G3

(±0.01-0.05mm) |

|

Type

|

Solid/Hollow

|

Solid

|

Solid

|

Solid

|

|

Density

|

Around: 0.85g/cm3

|

Around:1.4g/cm3

|

Around:1.1g/cm3

|

Around: 1.5g/cm3

|

|

Feature

|

Has good resistance, chemical resistance, low density (density less than water), low water absorption, the highest melting point

of the thermoplastic with excellent electrical insulator and low dielectric coefficient, often used for floating capacity

requirements, withblood transfusion, level calibration indicator.

|

it is similar to nylon, but slightly harder than nylon, slightly larger than the density recommended products applied to the

required low water absorption

|

The nylon has preferably the alkali metal, to adapt to the neutral characteristics of petroleum products and all kinds of chemical

products.

|

It have excellent chemical stability, resistance to corrosion, sealing, high lubricity non-tackiness, electrical insulation and

good anti-aging Stamina.

|

Application field

Best Selling

Packing&Shipping

Packing Method

1.Inner packing plastic bag+outer packing cartons.

2.Packed in wooden cases wrapped in plastic bags.

We supply customized packing service.

Shipping: Door-to-Door Air Freight & FOB & CFR

Delivery Method

Quickly delivery, with several delivery ways, such as DHL/FEDEX/UPS/TNT express, Air and Ocean shipping way. We have several express accounts and the cost is very cheap.

1.Are you a manufacturer or a trading company?

We are a 2000-square-meter factory located in Hebei, China.

2. Can I get a quote without drawings?

Sure, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.

3. Can you provide samples before mass production?

Sure, sample fee is needed, will be returned when mass production if possible.

4. How about the lead time?

Generally, 1-2 weeks for samples, 3-4 weeks for mass production.

5. How do you control the quality?

(1)Material inspection--Check the material surface and roughly dimension.

(2)Production first inspection--To ensure the critical dimension in mass production.

(3)Sampling inspection--Check the quality before sending to the warehouse.

(4)Pre-shipment inspection--100% inspected by QC assistants before shipment.

We are a 2000-square-meter factory located in Hebei, China.

2. Can I get a quote without drawings?

Sure, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.

3. Can you provide samples before mass production?

Sure, sample fee is needed, will be returned when mass production if possible.

4. How about the lead time?

Generally, 1-2 weeks for samples, 3-4 weeks for mass production.

5. How do you control the quality?

(1)Material inspection--Check the material surface and roughly dimension.

(2)Production first inspection--To ensure the critical dimension in mass production.

(3)Sampling inspection--Check the quality before sending to the warehouse.

(4)Pre-shipment inspection--100% inspected by QC assistants before shipment.

Hot Searches