- Product Details

- {{item.text}}

Quick Details

-

Size:

-

6000*1500*1500mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZZHL

-

Power:

-

7.5KW

-

Product name:

-

Plastic Bin High Pressure Cleaning Machine

-

Functionality of the machine:

-

- loading; - sink; - rinsing blowing (drying) unloading

-

The machine's design:

-

tunnel, modular type

-

Application:

-

bucket/box

-

Name:

-

Automatic plastic basket washing machine

-

Function:

-

Industrial plastic basket washing machine

-

Usage:

-

Professiona plastic basket washing machine

-

Material:

-

304 Stainless Steel

-

Item:

-

Electric plastic basket washing machine

-

Keywords:

-

High efficiency plastic basket washing machine

Quick Details

-

Warranty:

-

3 years

-

After-sales Service Provided:

-

Video technical support, Online support

-

Weight:

-

800KG

-

Size:

-

6000*1500*1500mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZZHL

-

Power:

-

7.5KW

-

Product name:

-

Plastic Bin High Pressure Cleaning Machine

-

Functionality of the machine:

-

- loading; - sink; - rinsing blowing (drying) unloading

-

The machine's design:

-

tunnel, modular type

-

Application:

-

bucket/box

-

Name:

-

Automatic plastic basket washing machine

-

Function:

-

Industrial plastic basket washing machine

-

Usage:

-

Professiona plastic basket washing machine

-

Material:

-

304 Stainless Steel

-

Item:

-

Electric plastic basket washing machine

-

Keywords:

-

High efficiency plastic basket washing machine

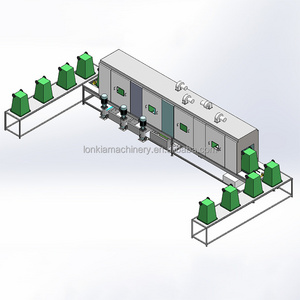

Plastic Bin High Pressure Cleaning Machine Turnover Plastic Box Crate Basket Washing Machine

Product Description

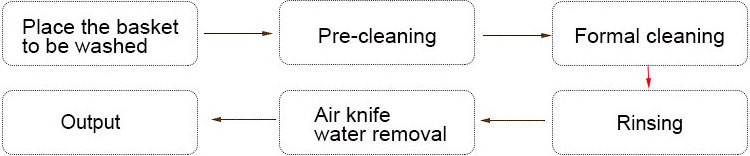

Work Process OF bucket/box washing machine:

Put into empty basket → pre-cleaning → main cleaning → rinsing → air knife dewatering → output

The box to be cleaned is placed upside down into the entrance of the cleaning machine, and driven by the motor, it enters the cleaning and disinfection tunnel. The bumps on the transmission chain carry animal materials to complete cleaning and disinfection. The first is to pre-clean, dilute and clean the box. Attached oil stains, duck feathers, and feces; the second link is the main cleaning process, using high temperature and high pressure spray water to disinfect and rinse the box; the third link is rinsing, and the water tank is directly cleaned with clean water in this process; In the full-covered cleaning tunnel, the boxes are fully flushed; after cleaning and disinfection, two high-pressure fans are composed of air knives to remove water from the plates. After air-drying, they leave the work area and the personnel take them out and place them.

The equipment is divided into three levels of cleaning, one air knife for water removal, each group of cleaning has independent circulating water tanks, spray devices, filtering devices, temperature control and heating (1.2 levels), water inlet and drainage devices, specific The process flow is carried out according to the actual situation of the box, for example, alkaline cleaning solution can be added for level 1 cleaning; sodium hypochlorite, chlorine dioxide, peracetic acid disinfectant can be added for level 2 cleaning; room temperature clean water for level 3 cleaning . The equipment is a customized model, but it is a general-purpose type, which can wash oil and dust tanks.

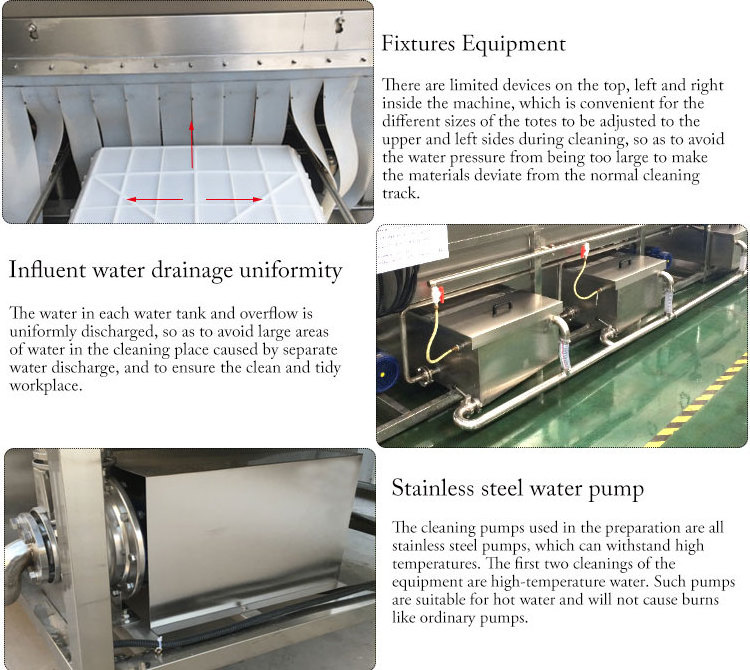

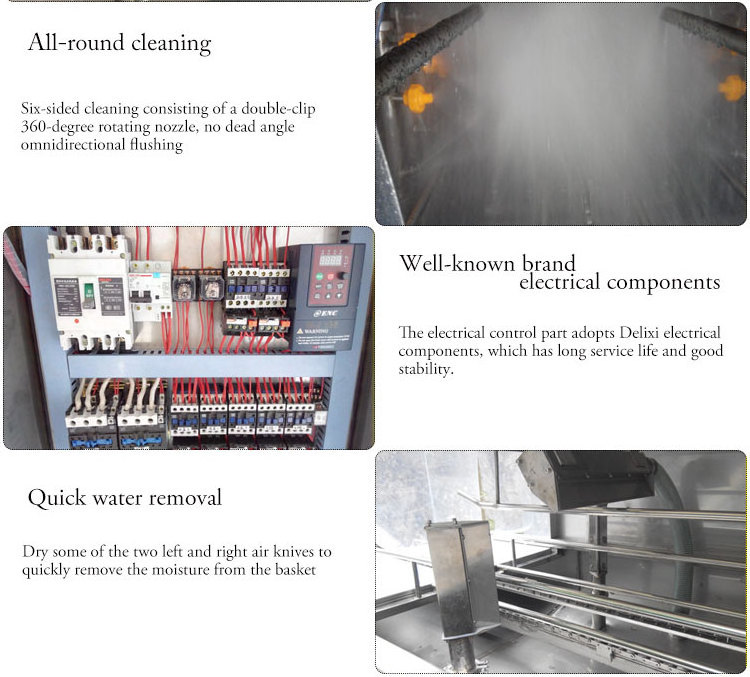

Main features:

1. In the pre-washing stage, the water pump sucks the water out of the pre-washing water tank and sprays it out through the nozzle, so that all sides of the basket are cleaned and sundries are removed. After cleaning, the sewage flows back to the water tank through

filtration and separation and sundries are removed.

2. The main cleaning stage is that the water pump will draw warm water from the main cleaning water tank and spray it out through the nozzle, so that all sides of the basket will be cleaned, and the remaining impurities and oil will be cleaned. After cleaning,the sewage will

2. The main cleaning stage is that the water pump will draw warm water from the main cleaning water tank and spray it out through the nozzle, so that all sides of the basket will be cleaned, and the remaining impurities and oil will be cleaned. After cleaning,the sewage will

flow back to the water tank through filtration and separation, and debris will be removed.

3.The bleaching stage is when the rinse water pump sucks the hot water out of the rinse water tank and sprays it out through the nozzle to rinse away the stains and cleaning agents on the basket. At the same time, disinfect and sterilize the cleaning materials and flow to the main cleaning water tank.

3.The bleaching stage is when the rinse water pump sucks the hot water out of the rinse water tank and sprays it out through the nozzle to rinse away the stains and cleaning agents on the basket. At the same time, disinfect and sterilize the cleaning materials and flow to the main cleaning water tank.

Scope of application:

The equipment is suitable for the cleaning and disinfection of the turnover boxes and stainless steel trays of the assembly line. It is mostly used for the treatment of turnover boxes such as animal husbandry, food, medical treatment, precision electronics, central kitchens, etc. The process is simple and automated, and the water source is recycled, saving Water and labor costs.

Product parameters

Please tell me your requirements,we can customize machine according to your requirements.

*If you can not open the links above on Alibaba APP on mobile phone, please use IE browser to visit our website: https://chinafoodmachine.en.alibaba.com

*If you can not open the links above on Alibaba APP on mobile phone, please use IE browser to visit our website: https://chinafoodmachine.en.alibaba.com

|

MODEL

|

HLXK-500

|

|

Item

|

Parameter

|

|

Material

|

SUS304 stainless steel

|

|

Power

|

15kw

|

|

Max Capacity

|

400pc/h

|

|

Physical Size

|

6300*1000mm

|

|

Voltage

|

220V/380V/480V/Customized

|

|

Washing speed

|

Adjustable

|

|

Heat type

|

Steam

|

Recommend Products

Hot Searches