- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Permendur

-

Shape:

-

bar

-

Material:

-

Soft magnetic alloy

-

Chemical Composition:

-

fe-co-v

-

Grade:

-

Permendur 49

-

Curie point(Tc/ ℃):

-

980

-

Surface:

-

Bright

-

Density(g/cm3):

-

8.2

-

Size:

-

Customized Size

-

Advantage:

-

High saturation permeability

-

MOQ:

-

10kg

-

Technology:

-

Cold Drawn

-

Sample:

-

Availiable

-

Keywords:

-

permendur rod

Quick Details

-

Application:

-

Electrical components

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Chengyuan

-

Model Number:

-

Permendur

-

Shape:

-

bar

-

Material:

-

Soft magnetic alloy

-

Chemical Composition:

-

fe-co-v

-

Grade:

-

Permendur 49

-

Curie point(Tc/ ℃):

-

980

-

Surface:

-

Bright

-

Density(g/cm3):

-

8.2

-

Size:

-

Customized Size

-

Advantage:

-

High saturation permeability

-

MOQ:

-

10kg

-

Technology:

-

Cold Drawn

-

Sample:

-

Availiable

-

Keywords:

-

permendur rod

Product Paramenters

Permendur

Chemical composition, %

|

C

|

Mn

|

Si

|

P

|

S

|

Cu

|

Ni

|

Co

|

V

|

Fe

|

||||||

|

(≤)

|

|

|

|

|

|

|

|

|

|

||||||

|

0.04

|

0.3

|

0.3

|

0.02

|

0.02

|

0.2

|

0.5

|

49.0-51.0

|

0.80-1.80

|

Bal.

|

||||||

Permendur

Physical properties

|

Density

(g/cm

3

)

|

Resistivity

(ΜΩ•m)

|

Curie point

(℃)

|

remanence

(T)

|

Yield Strength

(MPa)

|

Tensile strength

(Mpa)

|

Elongation

(%)

|

Elastic Modulus

Ksi

|

Magnetostriction coefficient

|

|

8.2

|

0.4

|

980

|

1.45

|

1280

|

1340

|

1

|

3x103

|

60x10

-6

|

Permendur

Magnetic properties

|

Product form

|

Magnetic induction intensity at different magnetic field strength (A/m)/T

|

|

|

|

|

|

Coercivity H

c

/(A/m)

|

|||||

|

|

B400

|

B800

|

B1600

|

B2400

|

B4000

|

B8000

|

|

|||||

|

|

≥

|

|

|

|

|

|

≤

|

|||||

|

Cold rolled strip

|

1.6

|

1.8

|

2

|

2.1

|

2.15

|

2.2

|

128

|

|||||

|

Wire, forged (rolled) material

|

...

|

...

|

...

|

2.05

|

2.15

|

2.2

|

144

|

|||||

Permendur

Physical properties/average linear expansion coefficient (10

-6

/℃)

|

Temperature

|

|

Coefficient of expansion

|

|

||

|

68°F

|

20°C

|

-6/°F

|

10

-6

/℃

|

||

|

392

|

200

|

5.28

|

9.5

|

||

|

752

|

400

|

5.61

|

10.1

|

||

|

1112

|

600

|

5.83

|

10.5

|

||

|

1472

|

800

|

6.28

|

11.3

|

||

Permendur

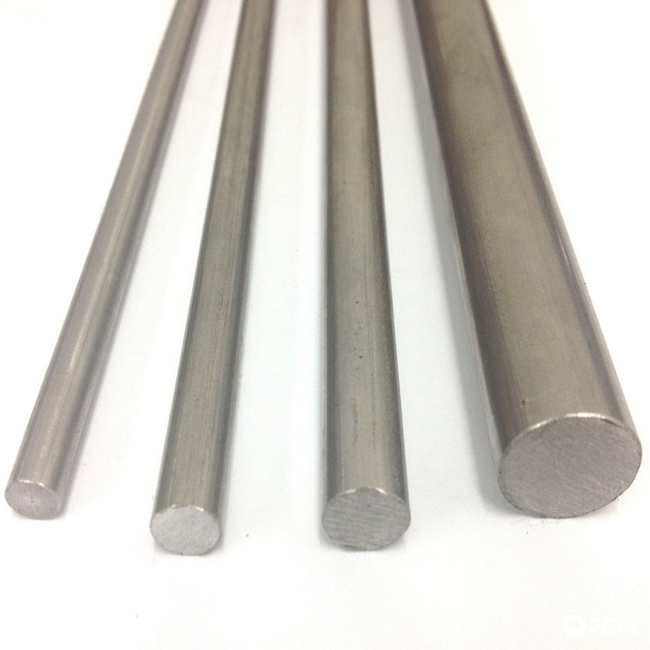

Supply form and specification

|

Form

|

Specification/mm

|

Delivery status

|

|

Bar

|

8.0-30.0

|

Hot rolled

|

|

|

30.0-180.0

|

Hot forging

|

|

Plate

|

3.5-30.0

|

Hot rolled

|

|

|

30.0-40.0

|

Hot forging

|

|

Strip

|

0.05-1.0

|

Cold rolled

|

Product Description

Permendur

is an iron-cobalt-vanadium soft magnetic alloy with high saturation magnetic flux density. Among the existing soft magnetic materials, this alloy has the highest saturation flux density (2.4T), a high DC permeability, and a very high Curie point ( 980℃). ), the saturation magnetostriction coefficient is the largest (60~100×10-6), at the same time it has a lower DC coercivity and a lower AC iron loss. Due to the high saturation magnetic induction, the volume of the motor can be significantly reduced when the motor of the same power is made, and when it is used as an electromagnet, it can produce a large attracting force under the same cross-sectional area. Due to the high Curie point, it can continue to work in a higher temperature environment where general soft magnetic alloys cannot work normally, and can maintain relatively good magnetic properties. It is worth noting that the alloy has a low resistivity (0.27μΩ·m) and is not suitable for use at high frequencies, and because of its high cobalt content (50%), it is expensive, easy to oxidize, and has poor plasticity.

Permendur

application range

Due to its large magnetostrictive coefficient,

Co50V2

is extremely suitable for magnetostrictive transducers, with high output energy and high working efficiency. It is suitable for light and small aviation and aerospace electrical components, such as microelectronic rotors, Electromagnet pole heads, relays, transducers, etc. Therefore, this material is widely used in the aerospace field as an armature punch of aerospace synchronization and torque motors.

Similar grades: AFK502 (France), (Russia),

Co50V2

(UK), Supermendur (US), 1J22 (CN)

Permendur

process performance

1.After

permendur

alloy is rapidly quenched at about 880℃, it can be processed into thin ribbons and filaments. The ribbons and wires can be punched, wound or processed into various shapes of components.

2.

permendur

alloy hot rolled (forged) material, cold drawn wire material and strip material can be cut and ground. When the alloy is processed into components and subjected to the final heat treatment of slow cooling, the plasticity is very poor, and it can only be slightly ground.

Recommend Products

Classification

Hot Searches