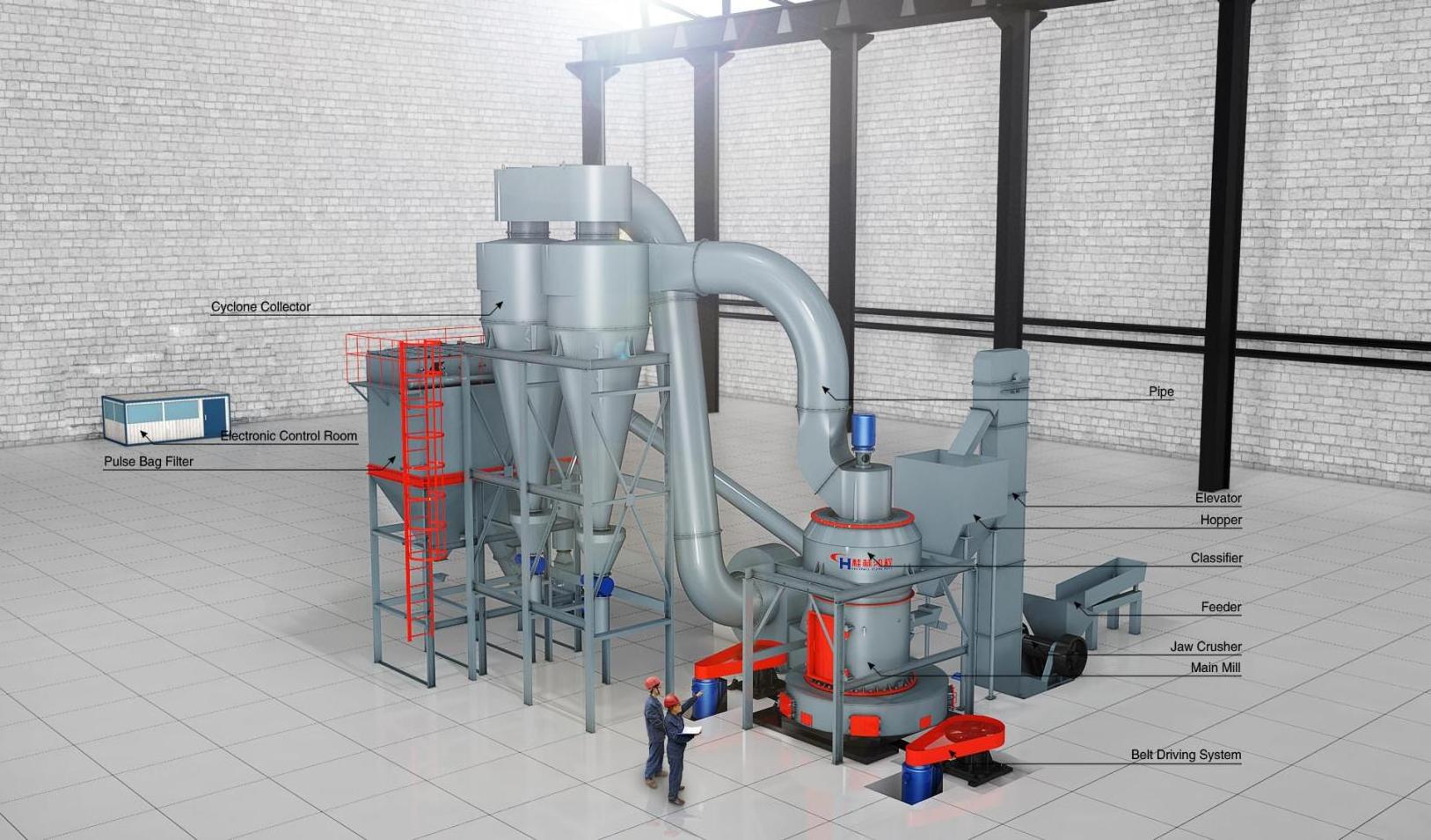

Working Principle of Vertical Roller Mill

Phase 1: Crushing

After crushed by hammer crusher, the big materials become small ones (15mm-50mm)

Phase 2: Grinding

The coarse material are sent to storage hopper by elevator and further sent to the middle of first dial evenly by the

electromagnetic vibrating feeder and feeding pipe.

Phase 3: Classifying

The materials will be driven to the edge of mill dial by centrifugal force and fall down into the ring, crushed and ground by roller and become powder. The high pressure centrifugal blower will inhale air from outside and blow the crushed materials to classifier.

Phase 4: Collection

The rotating turbo in the powder concentrator will make the unqualified coarse materials return to the mill and reground, while the qualified fineness will mix with the air and go into the cyclone and be discharged in the discharge bin, which is at the bottom of it. The air, which mixed with very little fineness, will be purified by impulse duster and discharged by blower and muffler.