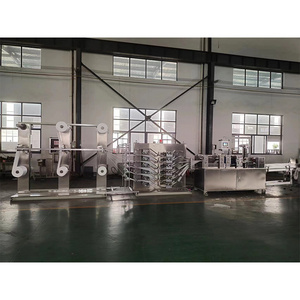

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

EAST

-

Voltage:

-

380V 50Hz

-

Power:

-

5.5KW

-

Weight:

-

6.0T

-

Control method:

-

PLC

-

Folding size:

-

1250 mm (width)

-

Folding type:

-

V folding

-

Finished product open size:

-

190±2mm X(130~250)

-

Applicable roll quantity:

-

50-100GSM(2ply/3 ply)tissue paper

-

Cloth core diameter:

-

76.2mm

-

Size:

-

1200*1250mm

-

Air pressure:

-

0.5mpa

-

Design speed:

-

100m/min

-

Embossing unit:

-

Steel Embossing

Quick Details

-

Production Capacity:

-

500~1000 sheet/min/Line

-

Processing Type:

-

Paper making Machine

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

EAST

-

Voltage:

-

380V 50Hz

-

Power:

-

5.5KW

-

Weight:

-

6.0T

-

Control method:

-

PLC

-

Folding size:

-

1250 mm (width)

-

Folding type:

-

V folding

-

Finished product open size:

-

190±2mm X(130~250)

-

Applicable roll quantity:

-

50-100GSM(2ply/3 ply)tissue paper

-

Cloth core diameter:

-

76.2mm

-

Size:

-

1200*1250mm

-

Air pressure:

-

0.5mpa

-

Design speed:

-

100m/min

-

Embossing unit:

-

Steel Embossing

| Finished products unfolded size |

200*(120-210)5L |

| Folding products size |

1200*1250mm |

| Raw material width | |

| Raw material diameter |

76.2mm |

| Raw materail core diameter |

76.2mm |

| Output(8 hours) |

4000-6000kg |

| Embossing unit |

steel to rubber ,steel to wool ,steel to steel embossing (customer choose) |

| slitting unit | Pneumatic slitting |

| Power | 7.5kw main motor |

| Vacuum suction unit | 22kw Fan |

| Pneumatic system | 3HP air compressor ,mini pressure 5kg/cm 2PA |

| Driving system | Timing belt |

| Dimension | 7950*2500*1850mm |

| Weight | 6.0T |

The Main Function

1,can order steel to rubber embossing rolls ,pneumatically separated.

2,Wallboard rack and Machine running stability is extremely googd and fast.

3Pneumatic jumbo roll loading ,pneumatic paper driving ,stepless speed additionustment .and web tension control

4,Equipped with roots type vacuum pump for stable running of machine

5.Make various products width as requirement.

6Equipped with edge embossing unit to keep the plies together .

7The machine will stop when the paper broken ,It avoid waste caused by no paper or paper broken.

8.The web can be threaded on the machine by the two jog buttons It'x more safety and easier to thread the web.

Paper Product Processing

SINOR GROUP CO.,LIMITED focus on Paper Processing Machine for more than 10 years in China Domestic Market.

WE have full experience on Paper Processing Machine, such as: Toilet Paper Making Machine, Napkin Tissue Making Machine, Facial Tissue Making Machine and also Packing Machine for this products,etc.

Upon more than 10 years experience in this field, SINOR starts to go aboard and open Foreign Market in different countries on recent years. In order to provide the Right & Best Machines for our customers in different countries, SINOR try our best to learn from customers and study national conditions from customer ’ s market.

Our mission is to provide a More Cost Efficient Solution for our customers. Suitable is the Best Way, Best for customers, for local market and even for our future. We treat it as our responsibility in every business.

Q: Can you provide the installation videos?

A: Yes, we will provide.

Q: What's the production time?

A: Generally it is 40-60 working days , it depends on your customized requirements.

Q: How long is your warranty?

A: One year of the machine, wearing parts not included.

Q: Can your company do customized machine?

A: Yes we can. We have 3 experienced engineers to support customized designs.

Q: How about your after-sales services?

A: We offer online instructions or onsite if needed.

Q: Can you provide the installation videos?

A: Yes, we will provide.