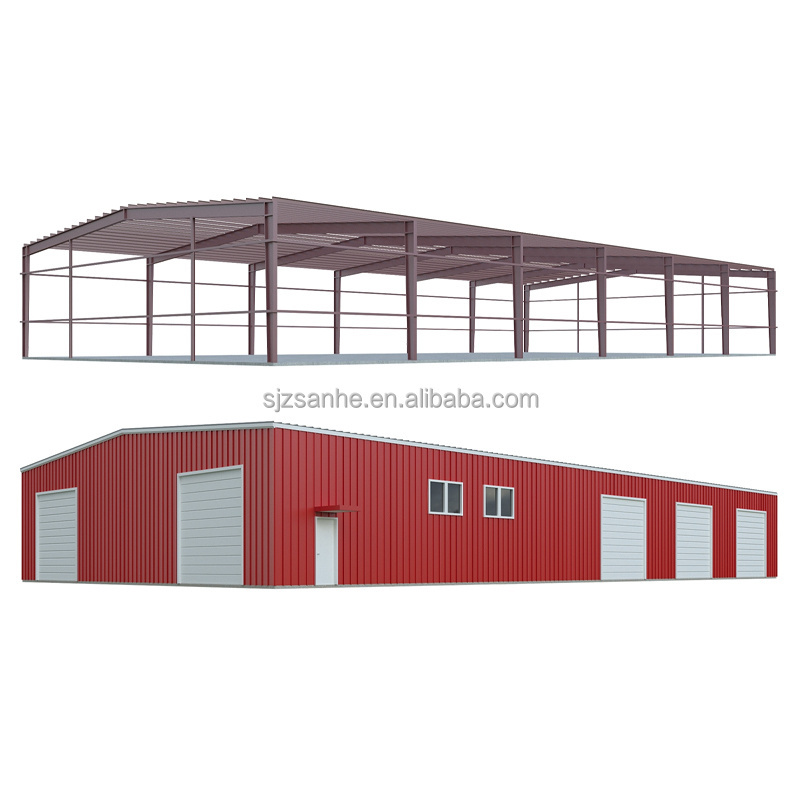

All the steel structure components are prefabricated , finished cutting , welding , drilling and painting in our factory .

structure prefabricated buildings have been widely used in commercial, agricultural, industrial and residential.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SANHE

-

Model Number:

-

Steel Metal Buildings

-

Delivery Time:

-

15-30 days

-

Product name:

-

Steel Metal Buildings

-

Certificate:

-

ISO9001:2008

-

Color:

-

Blue Red White Green

-

Purlin:

-

C.Z Shape Steel Channel

-

Roofing:

-

Sandwich Panel. Single Steel Sheet

-

Door:

-

Roller Door,Sliding door or other types

-

Main frame:

-

Steel Q355

-

Surface treatment:

-

1. Painting 2. Galvanized

-

Drawing design:

-

MTS, 3D3S, CAD etc.

-

Installation:

-

Engineers Guidance

Quick Details

-

Grade:

-

Q355B

-

Tolerance:

-

±1%

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

SANHE

-

Model Number:

-

Steel Metal Buildings

-

Delivery Time:

-

15-30 days

-

Product name:

-

Steel Metal Buildings

-

Certificate:

-

ISO9001:2008

-

Color:

-

Blue Red White Green

-

Purlin:

-

C.Z Shape Steel Channel

-

Roofing:

-

Sandwich Panel. Single Steel Sheet

-

Door:

-

Roller Door,Sliding door or other types

-

Main frame:

-

Steel Q355

-

Surface treatment:

-

1. Painting 2. Galvanized

-

Drawing design:

-

MTS, 3D3S, CAD etc.

-

Installation:

-

Engineers Guidance

Products Description

Prefabricated Steel Structure Metal Buildings Steel Structures Use

steel structure warehouse , metal workshop,

pole barns metal buildings

, poultry chicken house , cow shed , farm building ,

horse riding arena tent

, steel hangar , office building , prefab house , supermarket , carport , garage shed etc.

Steel Structure Warehouse Prefabricated Steel Workshop Pole Barns Metal Buildings For Wholesales

Get a Metal Building for your Business, Farm, or Hobby

Get a Metal Building for your Business, Farm, or Hobby

Materials Cost

Construction and material costs for traditional structures are much more expensive than a prefabricated steel or metal buildings,and as a result ,our products are more cost effective.

Quick Assembly

Pre-fabricated steel structures arrives at the construction site in ready-to-assemble sections.All you have to do is lay it out and about it together.As most kits arrive with all components included,they are simple to assemble and provide massive savings on labor and material costs.

Accurate Design

Metal and steel building templated are engineered,generated and manufactured using computer technology.

Improved Flexibility,Design and Portability

Prefab steel buildings are expandable and manufacturers are also very flexible and accommodating to design and engineer custom plan for you project,offering you more freedom in the design and layout of your building.In addition,you can simply add another section to the steel building if you need more space or disassemble the it and more it with you if need to be in another location.

Metal Buildings

Fabrication Production Process

.

Product Project

Steel Frame Construction Light Steel Structure Prefabricated Ready Warehouse

industrial building metal steel structure

P

ole Barns Metal Buildings in America

Most of the steel structure building bolt connection on site ,the wall and roof panel fixed on purlin by self-drilling screw.Which make the installation work easier.

We always stick to the concept of quality first, customer first, when you choose us, you will have peace of mind for many years to come.

Steel structure components:

Frame structure: the main frame of the industrial workshop is composed by H section steel, C/Z section steel; According to different regions, different temperatures and different requirements, maintenance structure can use single corrugated color steel sheet, double color plate + fiberglass, EPS sandwich panel, rock wool sandwich panel, PU sandwich panel.

prefab steel structure Warehouse

prefabricated metal workshop

industrial storage construction shed

Application

Our prefabricated steel structure buildings are pre-cut, pre-drilled, and ready for quick and efficient assembly. Steel buildings work for virtually any building application:Agricultural/ Barns/ Aircraft Hangars/ Welding Shops/ Commercial center/ Garages/ Storage/ Suburban Buildings/ Warehouses/ Workshops etc.

Main Product Material

|

Main steel frame

|

H section steel beam and columns ,Glavanized C purlin,Glavanized square pipe

|

|

Surface

|

Painted or Hot Dip Galvanized

|

|

Secondary frame

|

Tie Rod:Circular Steel Tube

|

|

|

Brace:Round Bar

|

|

|

Knee Brace:Angle Steel

|

|

Roof & Wall Panel

|

Sandwich Panel / Corrugated Steel Sheet, daylight panel

|

|

Window

|

PVC Steel or Aluminum Alloy Window

|

|

Door

|

Sliding Door or Rolling Up Door

|

|

Other accessory

|

Roof Gutter ;Rainspout ;Roof Ventilator

|

|

Service

|

Design, Fabrication, Installation and after-sale service

|

|

|

We can make quotation according to customer's drawing or detailed requirement; (size by length/width/height and wind speed), offering a

free design drawing and all detailed drawings for installation. |

|

|

Design software: Auto CAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures (Xsteel)V12.0.etc

|

|

Packing

|

According to customer's requirement

|

|

|

Load into 40/20GP, 40HQ or 40OT

|

|

International Stand Quality Control

|

|

Our steel structure products could accept be inspected by factory , by SGS , by clients etc.

Welcome to you visit our factory ! |

|

Full set service

|

|

1) Design to produce :

Our professional engineer team design the metal steel structure building pole barn kits , make quote , make drawing for you.Then our factory produce the high quality steel structure products for you .

|

|

2) Shipping :

We could help you arrange the shipping , you could also do it by yourself .

|

|

3) Installation :

THREE ways to help you on the installation:

1. We can offer you the manual include the photos and drawings, or some videos for

help you on the installation. And you will organize the local people to install it.

2. We can send our people to your site to guide your people to install.

3. You can send your people (engineers or the technician) to our company to study the installation

details. |

Packaing & Shipping

1, According to the size of the container 20 GP: Inside capacity is 5.69m x 2.34m x 2.18m,Gross weight 17.5 ton,volumn is 24-26m3; 40 GP: Inside capacity is 11.80m x 2.34m x 2.18m,Gross weight 22 ton,volumn is 54m3. 45 HQ: Inside capacity is13.58m x 2.34m x 2.71m,Gross weight 29 ton,volumn is 86m3.

2, Customers specifying freight forwarder or negotiable shipping methods.

3, All of the steel colums&beams ends and plates will be by the blanket 4, 40OT is preferred to loading the steel frames.

Contact Us

Hot Searches