- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220/380v Customzied

-

Power:

-

264000

-

Dimension(L*W*H):

-

5020*2220*2469mm

-

Weight:

-

10600 kg

-

Installation:

-

Engineer Guide

-

Usage:

-

Mining Crushing

-

Function:

-

Mining Crusher Equipment

-

Advantage:

-

High Efficiency Low Energy

-

Feeding size(mm):

-

340

Quick Details

-

Marketing Type:

-

New Product

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Nairy

-

Voltage:

-

220/380v Customzied

-

Power:

-

264000

-

Dimension(L*W*H):

-

5020*2220*2469mm

-

Weight:

-

10600 kg

-

Installation:

-

Engineer Guide

-

Usage:

-

Mining Crushing

-

Function:

-

Mining Crusher Equipment

-

Advantage:

-

High Efficiency Low Energy

-

Feeding size(mm):

-

340

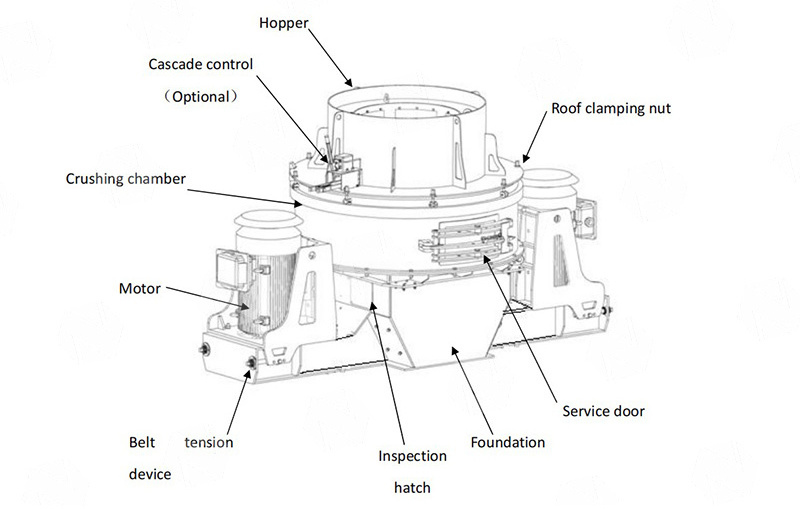

Product Overview

Introduction Of Sand Making Machine

The construction sand making machine goodly combines unique rotor design with effective by pass feeding system that is accurate and valid to control, which greatly improves production capability and product quality, and lowers production cost and consumption of wearing parts. In the construction sand making machine, with an optimized design, wearing parts are conveniently maintained and the time for replacing the wearing parts is short; and because automatic control and manual control systems are goodly combined, the workload of maintaining the equipment is lowered to the maximum extent.

Introduction Of

Silica Sand Plant

Silica sand plant

is widely used in all kinds of minerals, cement, construction sand, stone stock, slag, etc. Sand Making Machine is more productive than other kinds of crushers.

Sand For Plant

Working Principle

Sand for plant

adopts rock lined rotor that acts as a high velocitydry stone pump hurling a continuous rock stream into a stone lined crushing chamber.Material fed into the top of the machine is accelerated in the crusher's rock lined rotor,achieving exit velocities of up to 50-75 m/s. The rotor continuously dischargesinto the crushing chamber. This process replenishes the rock lining, while at the same time maintainsa rock-on-rock chain reaction of crushing and grinding.A second stream of material in a controlled quantity can be cascaded into the crushing chamberturbulence causing a supercharging of the particle population within the chamber, improving theenergy transfer, so as to increase crushing ratio. According tothis principle, the material in the chamber is impacted, grinded and crushed by several times. The crushed material is discharged from the output opening, goes through screen system, then forms closed loop. Throughout the whole crushing

process, the material impact and crush each other.

Features of

Sand Making Plant

1.Large handing capacity and high output.

2.Low wearing parts cost.

3.Perfect product shape.

4.Hydraulic devices are maintained easily.

5.Thinning oil lubricant and automatic.

6.Multi-functions and Flexible application.

Product Specifications

|

Model

|

Feeding size(mm)

|

Capacity(t/h)

|

Dimension(mm)

|

Weight(kg)

|

Power(kw)

|

|

NVS8418

|

340

|

125-156

|

5020*2220*2469

|

10000

|

2*90

|

|

NVS8422

|

340

|

150-198

|

5020*2220*2469

|

10200

|

2*110

|

|

NVS8426

|

340

|

175-244

|

5020*2220*2469

|

10600

|

2*132

|

|

NVS8432

|

340

|

200-310

|

5020*2220*2469

|

10800

|

2*160

|

|

NVS9944

|

400

|

315-385

|

5050*2434*2813

|

14000

|

2*220

|

|

NVS9950

|

400

|

320-440

|

5050*2434*2813

|

14300

|

2*250

|

|

NVS9963

|

400

|

420-560

|

5050*2434*2813

|

14600

|

2*315

|

Important Reminder:

1. The technical parameters are for reference only.

2. The product quotation is for reference only, based on the purchased model and configuration.

3. For more information, please call or consult customer service.

Product Details

Recommend Products

Cooperation Case

Our Certificate

Our Customers

Hot Searches