- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

forbona

-

Power:

-

5.8 W

-

Dimension(L*W*H):

-

1700mm*1800mm*1500mm

-

Weight:

-

750 KG

-

Production Capacity:

-

120--160PCS/MIN

-

Product name:

-

Shoe Cover Making Machine

-

Speed:

-

120-160pcs/min

-

Final products size:

-

400*160mm

-

Raw material:

-

Non-Woven Material

-

Suitable width of material roll:

-

350mm

-

Suitable diameter of material roll:

-

500mm

-

Suitable thickness of material:

-

20-40GSM

-

Suitable width of elastic:

-

4mm

-

Machine packing type:

-

Wooden case

-

After Warranty Service:

-

Video technical support

Quick Details

-

Voltage:

-

1 phase 220v

-

Marketing Type:

-

New product 2023

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

forbona

-

Power:

-

5.8 W

-

Dimension(L*W*H):

-

1700mm*1800mm*1500mm

-

Weight:

-

750 KG

-

Production Capacity:

-

120--160PCS/MIN

-

Product name:

-

Shoe Cover Making Machine

-

Speed:

-

120-160pcs/min

-

Final products size:

-

400*160mm

-

Raw material:

-

Non-Woven Material

-

Suitable width of material roll:

-

350mm

-

Suitable diameter of material roll:

-

500mm

-

Suitable thickness of material:

-

20-40GSM

-

Suitable width of elastic:

-

4mm

-

Machine packing type:

-

Wooden case

-

After Warranty Service:

-

Video technical support

Products Description

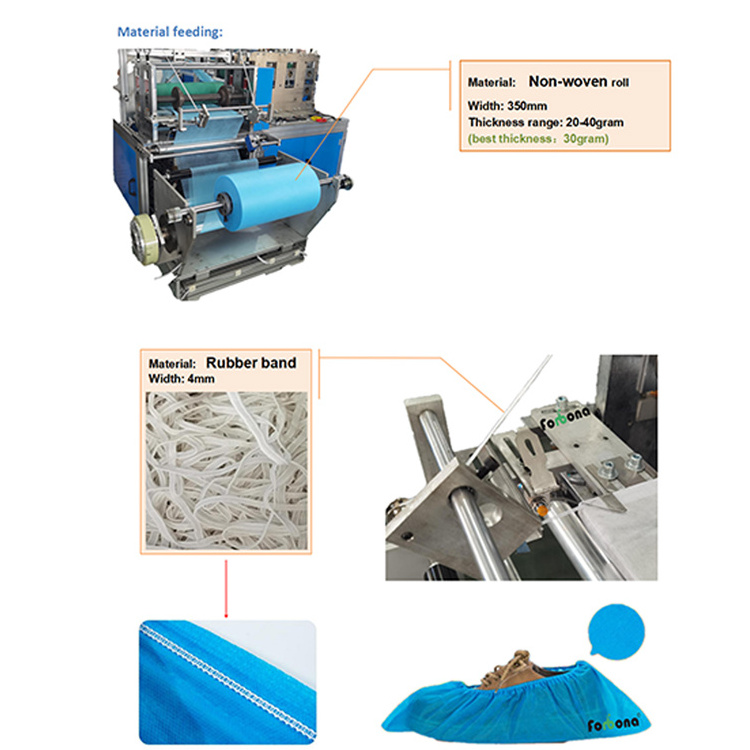

HIGH SPEED NON-WOVEN SHOE COVER MAKING MACHINE

( SPEED: 120-160pcs/min)

Sample:

standard machine to produce:400*160mm size of shoe cover.

other size customizable.

Performance and Characteristics:

1. The machine use to produce non-woven material shoe cover, good quality, low price,high output advantages, can completely replace manual shoe cover, save labor, reduce costs, can becustomized according to customer requirements, this machine is automated.

2. Automation of the whole process from feeding raw materials to layered products to counting products. With computer control and automatic tension control, hot hand electric welding can be debugged, both ends of shoe sleeve and rubber band can be effectively fixed, and the whole process from raw materials to finished products can be automated. Only one person is needed in the whole process of operation.

3. Frequency conversion speed regulation.

4. Delivery is the finished product.

5. Automatic constant temperature control.

6. Hot hand electric welding can be debugged.

Technical Data:

|

Suitable material

|

|

|

Non-woven

|

|

|||

|

Machine size

|

|

|

1700mm*1800mm*1500mm(L*W*H)

|

|

|||

|

Package size

|

|

|

BY SEA: 1800mm*1900mm*1760mm(L*W*H)

BY Flight: 1760mm*1900mm*1580mm(L*W*H)

|

|

|||

|

Capacity

|

|

|

120-160 Pcs/min

|

|

|||

|

voltage

|

|

|

220v/380v (according to customer requirement)

|

|

|||

|

Weight

|

|

|

Machine weight:750kg ;Packing weight:800kg

|

|

|||

|

Power

|

|

|

5.8kw

|

|

|||

|

Finished products size

|

|

|

400*160mm(L*W)

other size make according to customer requirement

|

|

|||

|

Material Feeding

|

|

|

Rubber band,Non-woven

|

|

|||

Production process:

Automatic feeding - importing - folding - connecting - cutting

Optional:

add machine parts to feed elastic on the bottom of shoe cover for non-slip.

sample:

you need follows machine parts:

More Products

About US

Production Line

Product Exhibition

Certifications

Packing & Shipping

FAQ

Hot Searches