- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1year

-

Place of Origin:

-

Shandong, China

-

Operating Current:

-

none

-

Application:

-

copper, stainless steel, steel etc.

Quick Details

-

Material:

-

Copper / Copper Alloy

-

Welding Current:

-

none

-

Operating Temperature:

-

600-800

-

Warranty:

-

1year

-

Place of Origin:

-

Shandong, China

-

Operating Current:

-

none

-

Application:

-

copper, stainless steel, steel etc.

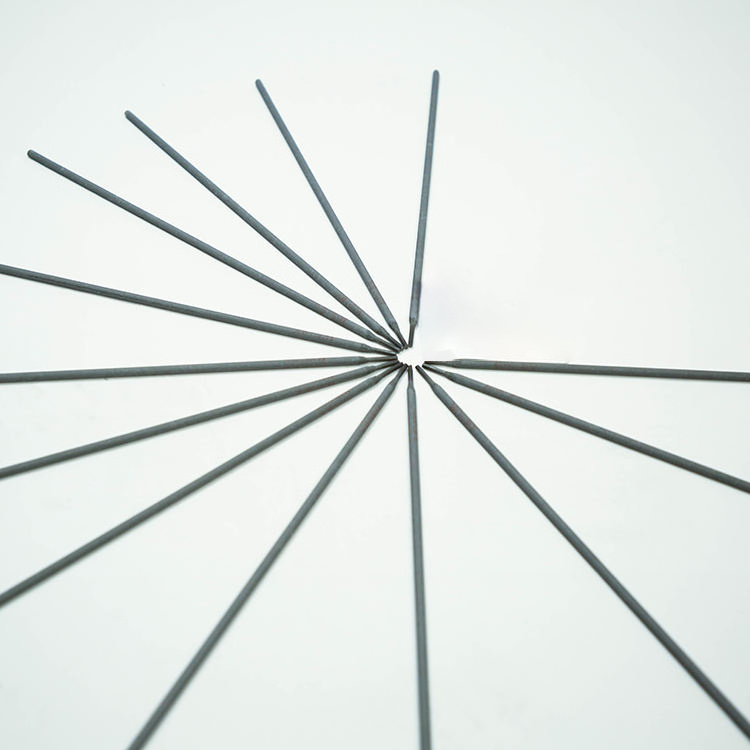

Product Paramenters

|

Warranty

|

3

|

|

Customized support

|

OEM, ODM

|

|

Place of Origin

|

China

|

|

Model Number

|

CHH307(E8015-B2)

|

|

Operating Current

|

AC DCEP DCEN

|

|

Welding Current

|

international standard

|

|

Operating Temperature

|

standard temperature

|

|

Application

|

structural steel

|

|

ISO 9001

|

approved

|

|

in stock

|

spot sales

|

Product Advantage

ATTENTION:

1. Before welding, the electrode shall be baked at 300-350℃ for 1 hour before use.

2. For surfacing welding of worn parts of high manganese steel, the fatigue layer shall be removed or treated with water toughness

or soldered with chromium manganese steel electrode (such as D277).

3. Due to the large yellow smoke during surfacing welding, attention should be paid to strengthen ventilation and operate in the

windswept position.

1. Before welding, the electrode shall be baked at 300-350℃ for 1 hour before use.

2. For surfacing welding of worn parts of high manganese steel, the fatigue layer shall be removed or treated with water toughness

or soldered with chromium manganese steel electrode (such as D277).

3. Due to the large yellow smoke during surfacing welding, attention should be paid to strengthen ventilation and operate in the

windswept position.

CHARACTERISTICS:

THD256 is the surfacing electrode of high manganese steel with low hydrogen potassium coating.Can be both ac and dc (ac welding, no-load voltage is not lower than 70V), surfacing welding should use small current, narrow welding, while the red heat immediately hammer or water quenching, in order to reduce the crack tendency.The surfacing metal is austenitic high manganese steel, which has

the characteristics of working hardening, toughness and wear resistance.

THD256 is the surfacing electrode of high manganese steel with low hydrogen potassium coating.Can be both ac and dc (ac welding, no-load voltage is not lower than 70V), surfacing welding should use small current, narrow welding, while the red heat immediately hammer or water quenching, in order to reduce the crack tendency.The surfacing metal is austenitic high manganese steel, which has

the characteristics of working hardening, toughness and wear resistance.

Product Application

APPLICATIONS:

it is suitable for surfacing welding of various crusher, high manganese rail, bucket, bulldozer, etc.

it is suitable for surfacing welding of various crusher, high manganese rail, bucket, bulldozer, etc.

Hot Searches