- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.9mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

RFM

-

Voltage:

-

380V 50Hz 3Phases

-

Dimension(L*W*H):

-

5000*800*1200Mm

-

Weight:

-

4500 kg

-

Feeding width:

-

Customer request

-

Marketing Type:

-

New Product 2021

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

raw material:

-

ppgi

-

feeding width:

-

as customers requirement

-

name:

-

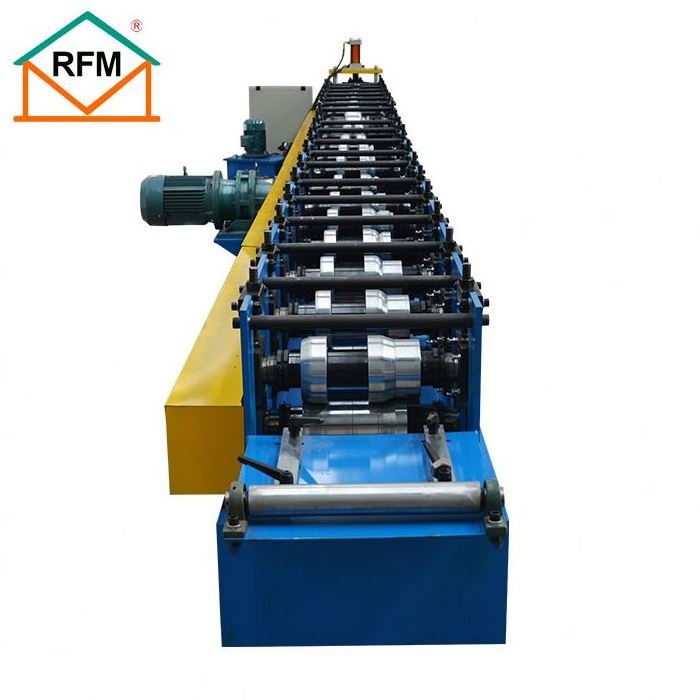

rain gutter machine

-

plc:

-

mitsubishi/delixi/siemens

-

operate style:

-

automatic

-

profiles:

-

as customers requirement

-

thickness:

-

0.3-0.9mm

-

cutting blade material:

-

cr12 with quenched treatment

Quick Details

-

Type:

-

Gutter machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

15-25M/Min

-

Rolling thinckness:

-

0.3-0.9mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

RFM

-

Voltage:

-

380V 50Hz 3Phases

-

Dimension(L*W*H):

-

5000*800*1200Mm

-

Weight:

-

4500 kg

-

Feeding width:

-

Customer request

-

Marketing Type:

-

New Product 2021

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

raw material:

-

ppgi

-

feeding width:

-

as customers requirement

-

name:

-

rain gutter machine

-

plc:

-

mitsubishi/delixi/siemens

-

operate style:

-

automatic

-

profiles:

-

as customers requirement

-

thickness:

-

0.3-0.9mm

-

cutting blade material:

-

cr12 with quenched treatment

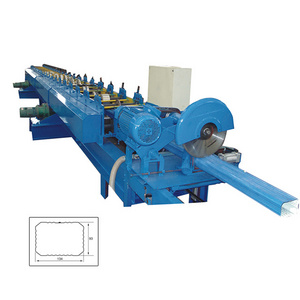

Customize various types of gutter forming machines

|

Name

|

roof gutter machine

|

|

color

|

customer request

|

|

Control system

|

PLC(imported Brand)

|

|

Cutting type

|

Hydraulic profile cutting

|

|

Material of rollers

|

CR 12 Quenched HRC 58-62

|

|

Shaft material

|

45# St

|

|

Material of cutting blade

|

Cr12 Heat Treatment

|

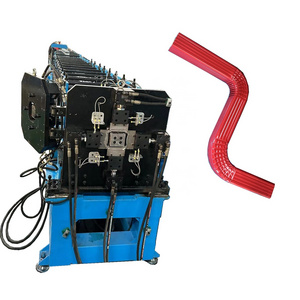

I can provide the gutter roll forming machine produced by the profile wholesaler that the construction team needs in the process of building civil houses

Click the image below to start online customization for the design you want.

We can provide gutter roll forming machine with high forming efficiency, convenient installation and low requirements for site flatness. Our newly-launched online factory inspection and online live broadcast methods satisfy customers’ requirements for being unable to come to our company for inspections due to various reasons, and hope that they can truly understand us; our company’s unique destructive test site The vigorous percussion of the live broadcast on the rollers also meets the requirements of customers who want to be able to truly see our commitment to the high quality of the machine.

Rollers

High quality rollers will help to produce the beautiful and high quality profile. That will satisfy your customers.

Using high qualiy thick shaft, the strength is more durable

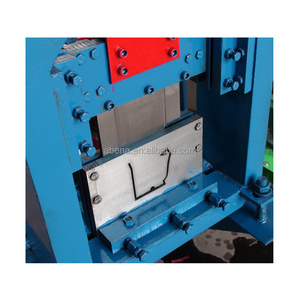

Cutting head

Blade material: Cr12MOV, forged by heat treatment. The cutting head adopts a high-quality electro-hydraulic cutting system and,

because the cutting method is stable, the cross section of the metal plate is neat.

Liming Stamping Form Machine Co.,Ltd. occupies an area of 156,000 square meters and 6 large production plants. It has been established in 1996 with many years of production experience, serving 156 countries, 4 international machinery patents, 10 Chinese machinery patents, nationally certified high-tech company.China's top three steel-building materials equipment factories.We brought in the most advanced software and CNC lathes, in order to ensure that every step is in the correct way.

This is a test of the hardness and speed of the machine parts by our engineers to ensure that the machine runs stably at high speed

.

We have a complete after-sales service system, engineers can go to the customer’s local training and maintenance.

A roll forming machine manufacturer with 26 years of forming experience in China, we can customize the product machine according to your requirements, not just the size of the product on this page.

Q: Can you customize the machine from your company?

A: Of course, we can manufacture the machine according to your customized size demand.

Q: How is the quality? Is there any department related to quality control?

A: All raw materials we use are quality controlled. Workers will take care of every detail when handling production and packaging. The quality control department is responsible for the quality of each process.

Q: Is the packaging form?

A: Yes, of course! All our machines will be packaged in dust and water proof, and they can be reinforced after loading to fully meet export packaging standards.

Q: How about after-sales service?

A: TM is online 24 hours a day, and you can also contact them via email, Skype, MSN, whatsapp. and many more Two-year warranty and parts replacement.

Hot Searches