- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

customer demand

-

Power:

-

127.5KW

-

Dimension(L*W*H):

-

2950*1320*1500mm

-

Weight:

-

1600 kg

-

Marketing Type:

-

New Product 2024

-

Application::

-

paper egg carton

-

Automatic Grade::

-

semi-Automatic

-

Name::

-

paper egg carton making machine

-

Control:

-

PLC

-

Color:

-

Customer's Requirement

Quick Details

-

Production Capacity:

-

4000pcs/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

CGY

-

Voltage:

-

customer demand

-

Power:

-

127.5KW

-

Dimension(L*W*H):

-

2950*1320*1500mm

-

Weight:

-

1600 kg

-

Marketing Type:

-

New Product 2024

-

Application::

-

paper egg carton

-

Automatic Grade::

-

semi-Automatic

-

Name::

-

paper egg carton making machine

-

Control:

-

PLC

-

Color:

-

Customer's Requirement

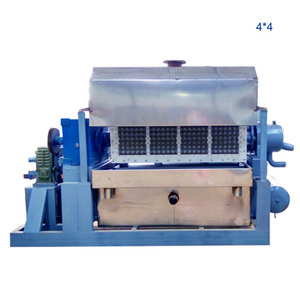

India hottest industrial packing pulp molding machine

paper egg carton making machine/electronic products paper tray equipment with drying equipment(customzied)

Features for electronic products paper tray equipment

1.This machine mainly produce the pulp moulded products,such as egg tray ,egg box, fruit tray,

coffee tray, red wine protect tray,spare parts tray,artware protect tray, the mould can be customized,you just provide sample ,we will make mold according to your sample .

2.The material for the molded pulp products is waste paper,corrugated paper,waste newspaper,magazine.

3.We have different types moulding machine for choosing according to your requirements.

And we will supply all round service for inquirying, price, technique teaching, installation and matainence .

4 ,electronic products paper tray equipment Fuel can be coal , natural gas ,diesel , wood

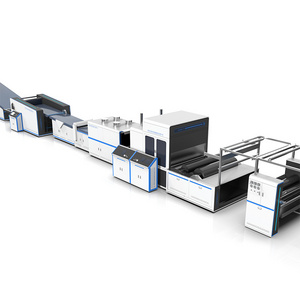

Production and working flow for electronic products paper tray equipment

A. Pulping system: Hydrpulper, Pulp pump, Sewage pump, Air compressor, Agitator;

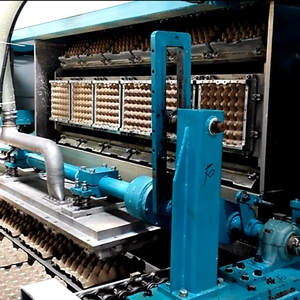

B. Forming system: Forming machine, Mould, Vacuum pump, High pressure washer, Baler;

C. Drying system: Cart-like brick kiln drying, traditional conveyor belt or metal multi-layer

Technical parameter of electronic products paper tray equipment

(please kindly tell me 1.what capacity per hour you want 2.which model do you like3.what kind tray you want to produce,better provide your sample picture,our machine capacity and mold both can customized.Provide your details requirment will help us recommend you suitable machine)

|

Model |

Capacity/h |

Product line type |

power |

Drying method |

|

FXPT-1000A 1*3 |

800-1000pcs/h |

Semi-automatic |

28kw |

Natural drying |

|

FXPT-1500 1*4 |

1500pcs/h |

automatic |

34kw |

Natural drying |

|

FXPT-2000 3*4 |

2000pcs/h |

Semi-automatic /automatic can be choosed |

49kw |

Automatic belt drying or build kiln drying |

|

FXPT-2000A 2*3 |

2000pcs/h |

Automatic |

41.5kw |

Build kiln drying |

|

FXPT-2500 4*4 |

2500pcs/h |

4*4 full automatic |

60kw |

Automatic belt drying |

|

FXPT-3000 4*8 |

3000pcs/h |

4*8 full automatic |

116kw |

Automatic belt drying |

|

FXPT-4500 5*8

|

4500pcs/h |

5*8 full automatic |

130kw |

Automatic belt drying |

Sample room:

Plant and machines:

Packing and Delivery to the port:

Our services:

1, we will provide all the machines for the complete production according to customer's requirements.

2, we will provide complete service for factory layout and other informations to help customer to build the factory.

3, we can also provide the raw material to the customer if you need.

4, we will provide good service for machine installation and trainning,

until the customers can run the machines and make stably production.

5. we will provide turkey project

6. before delivery, welcome you test machine and check machine quality and fianl product