A. Performance characteristics:

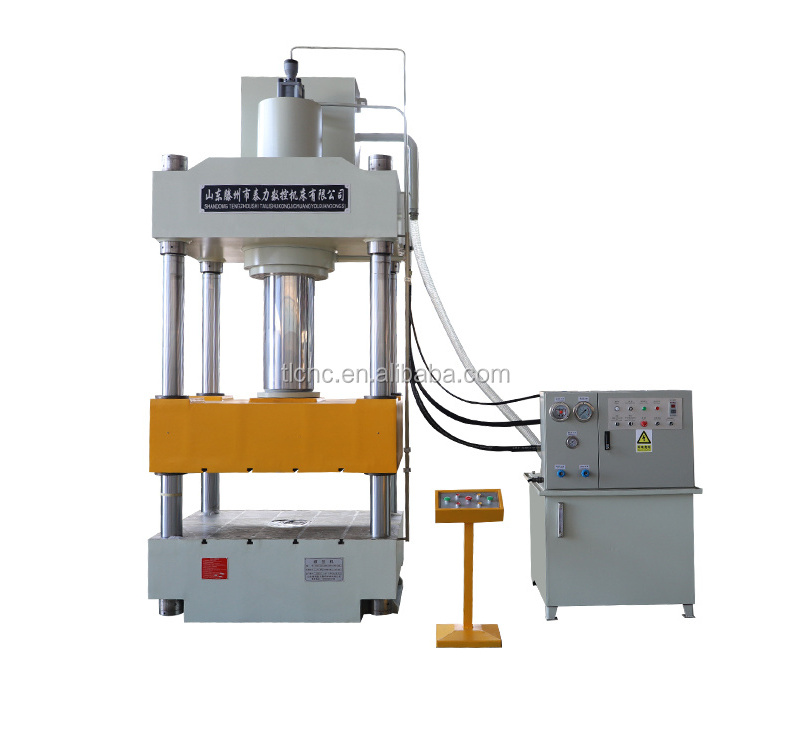

● Three-beam, four-post structure, economical and practical, convenient maintenance.

● The hydraulic control adopts the integrated cartridge valve integrated system, which reduces the leakage point, has a small hit, reliable operation, and long service life.

● It can realize two molding processes of constant pressure and fixed stroke, and optional pressure holding delay function can be selected, and the delay time can be adjusted.

● The working pressure and stroke can be adjusted within the specified range according to process requirements, and the operation is simple.

● Using centralized control of buttons, it has two operation modes: manual adjustment and semi-automatic operation.

- Product Details

- {{item.text}}

Quick Details

-

Return Force (kN):

-

3150 kN

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Taili

-

Year:

-

2020

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

custom made

-

Weight (T):

-

11 T

-

Model Number:

-

YQ32-315T

-

Motor Power (kw):

-

15 kw

-

Advantage:

-

High Precision

-

Color:

-

Customized

-

Power(W):

-

15kw

-

Style:

-

Servo Hydraulic Press

-

Feature:

-

Pressure

-

Technology:

-

315 Ton Hydraulic

-

Nominal Force (kN):

-

3150 kN

-

Certification:

-

CE ISO

Quick Details

-

Machine Type:

-

Four-column Three-beam Hydraulic Press

-

Slide Stroke (mm):

-

900

-

Ejector Force (kN):

-

3150

-

Return Force (kN):

-

3150 kN

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Taili

-

Year:

-

2020

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

custom made

-

Weight (T):

-

11 T

-

Model Number:

-

YQ32-315T

-

Motor Power (kw):

-

15 kw

-

Advantage:

-

High Precision

-

Color:

-

Customized

-

Power(W):

-

15kw

-

Style:

-

Servo Hydraulic Press

-

Feature:

-

Pressure

-

Technology:

-

315 Ton Hydraulic

-

Nominal Force (kN):

-

3150 kN

-

Certification:

-

CE ISO

Product Description

A hydraulic press is a machine that uses liquid as the working medium and is based on Pascal's principle to transfer energy to achieve various processes. Hydraulic machine is generally composed of three parts: the machine (main machine), power system and hydraulic control system. The hydraulic presses are classified into valve hydraulic presses, liquid hydraulic presses, and engineering hydraulic presses. The following editors will introduce to you the advantages and advantages of hydraulic presses.

Advantage

Compared with the traditional stamping process, the hydroforming process has obvious technical and economic advantages in reducing weight, reducing the number of parts and molds, increasing rigidity and strength, and reducing production costs. It has been obtained in the industrial field, especially in the automotive industry. More and more applications.

In the automotive industry, aviation, aerospace and other fields, reducing structural quality to save energy during operation is a long-term goal for people, and it is also one of the development trends of advanced manufacturing technology. Hydroforming is an advanced manufacturing technology to achieve lightweight structure.

Hydraulic forming is also known as "internal high pressure forming". Its basic principle is to use the tube as a blank, and at the same time, apply the axial thrust to the two ends of the tube while feeding the ultra-high pressure liquid inside the tube. Under the combined action of two external forces, the tube blank material undergoes plastic deformation, and finally adheres to the inner wall of the mold cavity to obtain a hollow part whose shape and accuracy meet the technical requirements.

|

Four-Column Hydraulic Press

|

Nominal Force

|

Table Dimension(LR*FB)

|

Slide Stroke

|

Max Opening Height

|

Descending Speed

|

Returning Speed

|

Pressing Speed

|

Motor Power

|

||

|

Unit

|

kn

|

mm

|

mm

|

mm

|

mm/s

|

|

|

kw

|

||

|

YQ32-63T

|

630

|

550*500

|

400

|

600

|

130

|

150

|

15-29

|

5.5

|

||

|

YQ32-100T

|

1000

|

640*550

|

300

|

600

|

60

|

64

|

10-17

|

5.5

|

||

|

|

|

700*620

|

500

|

800

|

|

|

|

|

||

|

YQ32-160T

|

1500

|

700*700

|

500

|

900

|

80

|

76

|

10-16

|

7.5

|

||

|

YQ32-160T

|

1600

|

800*800

|

500

|

900

|

100

|

76

|

10-16

|

7.5

|

||

|

YQ32-200T

|

2000

|

800*800

|

500

|

900

|

100

|

110

|

8-13.5

|

7.5

|

||

|

|

|

1000*1000

|

600

|

1000

|

150

|

100

|

8-13.5

|

|

||

|

YQ32-250T

|

2500

|

800*800

|

500

|

900

|

80

|

95

|

15-20

|

11

|

||

|

|

|

1200*1000

|

600

|

1100

|

120

|

80

|

10-15

|

|

||

|

YQ32-315T

|

3150

|

800*800

|

500

|

900

|

75

|

83

|

6-12

|

15

|

||

|

|

|

1000*1000

|

500

|

1000

|

100

|

|

|

|

||

|

|

|

1260*1160

|

600

|

1100

|

105

|

|

|

|

||

|

YQ32-400T

|

4000

|

1000*1000

|

500

|

1000

|

100

|

74

|

8-12.5

|

18.5

|

||

|

|

|

1200*1200

|

700

|

1200

|

100

|

|

|

|

||

|

|

|

1400*1400

|

1000

|

1600

|

120

|

|

|

|

||

|

YQ32-500T

|

5000

|

1400*1400

|

900

|

1500

|

80-100

|

71

|

12-16

|

15*2

|

||

|

|

2500*2

|

2200*1500

|

800

|

1400

|

100

|

80

|

5-12

|

|

||

|

YQ32-630T

|

6300

|

1600*1600

|

900

|

1500

|

100

|

10-17

|

75

|

18.5*2

|

||

|

|

3150*2

|

2400*1800

|

800

|

1400

|

110

|

10-15

|

105

|

|

||

|

YQ32-800T

|

8000

|

1800*1800

|

1000

|

1600

|

120

|

74

|

12-18

|

22*2

|

||

|

|

4000*2

|

2500*1800

|

900

|

1500

|

150

|

125

|

12-18

|

|

||

|

YQ32-1000T

|

10000

|

1800*1800

|

1000

|

1600

|

90

|

62

|

8-13.5

|

30*2

|

||

|

|

5000*2

|

2500*1800

|

900

|

1600

|

100

|

72

|

|

|

||

Features

Detailed Images

Optional accessories or features:

● Mobile workbench

● Touch mode industrial display

(Punching slow)

● Hydraulic system heating and cooling device

● Photoelectric protection device

● Beating device

● Floating rail and rolling bracket for mold change

● Die change trolley

● Slider safety bolt

● Mould quick clamping mechanism

● Mould heating and temperature control device

● Stroke, pressure, speed digital display, numerical control device

● PLC programmable controller

● Blank ring and drive system, displacement sensing device.

Why Choose Us

Packing&Shipping

1. Good environmental protection performance. Nowadays, the requirements of environmental protection are getting higher and higher in all countries in the world.

2. Strong barrier properties. The purpose of export wooden box packaging is to prevent the entry of oxygen, prevent oxidation, or slow down the oxidation rate. Our export wooden box packaging has strong barrier properties to ensure the quality of the goods.

3. Good impact resistance. When there is an impact during transportation, our export wooden box packaging has a certain impact resistance to protect the goods from damage.

Certifications

Since the establishment of our company for more than 10 years, we have obtained various certificates, passed the national CE ISO certificate and exported products to all over the world.

After Sales Service

24-hour hotline service:

Site:Jiangtun Town, Tengzhou City, Shandong Province, China

Contact number:

00-86-178-5358-8759

Wechat:

00-86-178-5358-8759

Whatsapp:

00-86-178-5358-8759

Company Introduction

Shandong Tengzhou Taili CNC Machine Tool Co., Ltd

.

is a professional manufacturer of designated forging equipment in the former Ministry of Machinery. It is located in the hometown of Mozi, Tengzhou City, Shandong Province, Yimeng in the east, Weishan Lake in the west, Jiangsu in the south, and Confucius hometown in the north Qufu. Tengzhou has a long history and culture and a developed industrial economy. The National Highway 104, the Beijing-Fuzhou Expressway, and the Beijing-Shanghai Railway run through the north and south of Tengzhou, and the traffic conditions are very convenient. The company is located in the Economic Development Zone of Tengzhou Industrial Park. The company has advanced processing equipment and a perfect quality management system, and has taken the responsibility to improve the overall level of domestic advanced manufacturing and the industrialization of numerical control technology. With the enterprise spirit of "honesty, dedication, pragmatism, and customer first", we serve customers Provide excellent products and quality services, and strive to build Lunan forged aircraft carriers.

Our Services & Strength

Company picture Tengzhou Taili CNC Machine Tool Co., Ltd. is a professional manufacturer of universal CNC forging machine tools.

General-purpose machine tools include YQ32 series four-column hydraulic presses, Y27 series single-acting sheet drawing machine,Y28 series double-acting sheet drawing machine, YLM series. Gantry hydraulic press, YQ41 series single column (single arm)hydraulic press, QC12Y series ordinary hydraulic swing type shearing machine, QC12K series CNC swing type shearing machine, QC11Kseries CNC gate type shearing machine, Q11 series mechanical shearing machine, WC67Y series General hydraulic bending machine,WC67K series CNC bending machine, YL21 series hydraulic press, JC23 / J23 series open tilting press, J21 / J21S / JC21 series open fixed table press, radial drilling machine and other products Used in automotive metallurgy, chemical industry, machinery, aviation, electronics, electrical appliances, agricultural machinery, hardware and other industries, and sold to the international market. The company can help you design and customize various special-shaped forging machine tools according to your requirements.

General-purpose machine tools include YQ32 series four-column hydraulic presses, Y27 series single-acting sheet drawing machine,Y28 series double-acting sheet drawing machine, YLM series. Gantry hydraulic press, YQ41 series single column (single arm)hydraulic press, QC12Y series ordinary hydraulic swing type shearing machine, QC12K series CNC swing type shearing machine, QC11Kseries CNC gate type shearing machine, Q11 series mechanical shearing machine, WC67Y series General hydraulic bending machine,WC67K series CNC bending machine, YL21 series hydraulic press, JC23 / J23 series open tilting press, J21 / J21S / JC21 series open fixed table press, radial drilling machine and other products Used in automotive metallurgy, chemical industry, machinery, aviation, electronics, electrical appliances, agricultural machinery, hardware and other industries, and sold to the international market. The company can help you design and customize various special-shaped forging machine tools according to your requirements.

FAQ

Q1: Are you a trading company or a manufacturer?

A1: We are an honest manufacturer. We welcome you to visit our factory.

Q2: How long is your delivery time?

A2: Most of our products are made-to-order products, which are determined according to quantity and other requirements. If there is stock, usually 3-5 days delivery, we will complete the delivery with quality and quantity.

Q3: Do you provide samples? Is it free or extra?

A3: Yes, we can provide you with samples. As for the cost, we can negotiate with each other.

Q 4: How to pay?

A4: First of all, we negotiate, usually 30% in advance, and the remaining 70% before delivery. We support various payment methods such as wire transfer and letter of credit.

Q5: How long is the warranty?

A5: The quality of our machines is guaranteed. One year warranty and lifetime maintenance, of course, mainly based on the contract we negotiate.

Hot Searches