- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1200

-

Voltage:

-

220V,Customizable

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Dession

-

Dimension(L*W*H):

-

1488*1080*1490mm

-

Main Function:

-

Bag forming filling sealing

-

Packaging Range:

-

Max.10kg

-

Packaging Speed:

-

Max.80bags/min

-

Film Width:

-

Max.1020mm

-

Bag Length:

-

Max.500mm

-

Bag Width:

-

Max.500mm

-

Film Thickness:

-

0.04~0.08mm

-

Roll Diameter:

-

Max.320mm

-

Optional Device:

-

Gusseted bag device, bag punching device

Quick Details

-

Function:

-

FILLING, Wrapping, Labeling, Sealing

-

Packaging Type:

-

Stand-up Pouch, Bags, Film, Pouch, sachet

-

Packaging Material:

-

Plastic

-

Weight (KG):

-

1200

-

Voltage:

-

220V,Customizable

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Dession

-

Dimension(L*W*H):

-

1488*1080*1490mm

-

Main Function:

-

Bag forming filling sealing

-

Packaging Range:

-

Max.10kg

-

Packaging Speed:

-

Max.80bags/min

-

Film Width:

-

Max.1020mm

-

Bag Length:

-

Max.500mm

-

Bag Width:

-

Max.500mm

-

Film Thickness:

-

0.04~0.08mm

-

Roll Diameter:

-

Max.320mm

-

Optional Device:

-

Gusseted bag device, bag punching device

Hot Sales 2kg 5kg Bigger Bag Frozen Food Packaging Machine Frozen French Fries Weighing Packing Machine

Machine Application

Vertical form fill seal (VFFS) packaging machines are used in almost every industry today, for good reason: They are fast, economical packaging solutions that conserve valuable plant floor space.

Whether you're new to packaging machinery or already have multiple systems, chances are you're curious as to how they work.

Vertical Form Fill Sealing Machine (VFFS) is used for packing many different products:

1. Food Industry: peanuts, popcorn, jelly, data, garlic, beans, grains, soybeans, pistachios, walnuts, rice, corn, sunflower seeds, melon seeds, coffee beans, potato chips, banana chips, plantain chips, chocolate ball, shrimp, sweet candy, sugar, tea, herbs, puffed food, dry food, frozen food, frozen vegetables, frozen pea, frozen fish ball, frozen pie, and other granule products.

2. Pet Food Industry: dog food, bird food, cat food, fish food, poultry food and etc.

3. Hardware Industry: plastic pipe elbows, nails, bolts and nuts, buckles, wire connectors, screws and other construction products.

Machine Parameters

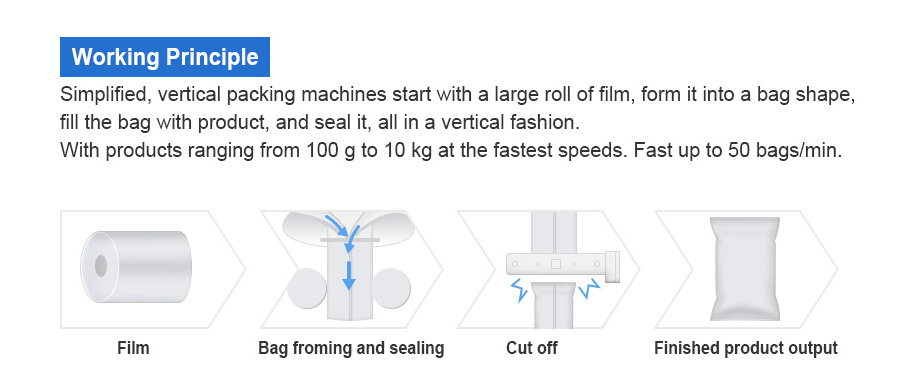

Simplified, vertical packing machines start with a large roll of film, form it into a bag shape, fill the bag with product, and seal it, all in a vertical fashion.

With products ranging from 100 g to 10 kg at the fastest speeds. Fast up to 3600 bags/hour. Maximum package size L: 50 cm, W: 50 cm.

|

Model

|

DS-420AZ

|

DS-520AZ

|

DS-620AZ

|

|

Film Width

|

Max.420mm

|

Max.520mm

|

Max.620mm

|

|

Filling Range

|

150~1500ml

|

150~2000ml

|

150~4000ml

|

|

Bag Length

|

80~300mm

|

80~350mm

|

150~350mm

|

|

Bag Width

|

60~200mm

|

80~250mm

|

200~350mm

|

|

Packaging Speed

|

5~60bags/min

|

10~50bags/min

|

5~50bags/min

|

|

Machine Power

|

220V, 50/60HZ, 2.2KW

|

220V, 50/60HZ, 3KW

|

220V, 50/60HZ, 3KW

|

|

Machine Size

(L*W*H)

|

1217*1015*1343mm

|

1488*1080*1490mm

|

1700*1250*1780mm

|

|

Machine Weight

|

650KG

|

750KG

|

850KG

|

Machine Features

1. The new design, beautiful appearance, the structure is more reasonable, more advanced technology.

2. English and Chinese screen display. PLC control, servo motor, very easy to operate. Do not need to stop machine to adjust any parameters.

3. Fully automatic bag forming, dosing Filling, sealing, coding, conveying, counting can be finished in one operation, most labor-saving equipment.

4. High quality stainless steel, suitable for GMP, good for food packaging with high standard.

5. Horizontal, vertical temperature control, suitable for various of mix film, PE film packing material.

6. Pocket diversification, can provide customers with pillow bags, angled bags, hanging-hole bags, vertical bags, punched bags, etc.

7. A variety of automatic alarming protective function, maximum limit to reduce wear and tear.

8. Double sever motors, drawing film position accurately, and the speed is faster.

9. Temperature independent control system, precision get to ±1°C.

2. English and Chinese screen display. PLC control, servo motor, very easy to operate. Do not need to stop machine to adjust any parameters.

3. Fully automatic bag forming, dosing Filling, sealing, coding, conveying, counting can be finished in one operation, most labor-saving equipment.

4. High quality stainless steel, suitable for GMP, good for food packaging with high standard.

5. Horizontal, vertical temperature control, suitable for various of mix film, PE film packing material.

6. Pocket diversification, can provide customers with pillow bags, angled bags, hanging-hole bags, vertical bags, punched bags, etc.

7. A variety of automatic alarming protective function, maximum limit to reduce wear and tear.

8. Double sever motors, drawing film position accurately, and the speed is faster.

9. Temperature independent control system, precision get to ±1°C.

Machine Details

Machine Control Center

The packaging parameters setting is set on the HMI screen (human machine interface). A pulse is generated for machine movement, and this is transferred to the PLC (programmable logic controller).Including packaging size, packaging weight, packaging speed, etc.

Multi-heads Combination Scale

The standard multi-head combination scale, rapid and accurate, weighs granules in a combined way. It is suitable for various products. With independent HMI screen and monitoring system, it is easy to operate and reduce failure rate.

Film Holder & Bag Former

When the VFFS packaging machine is operating, the film is usually pulled off the roll by film transport belts, which are positioned to the side of the forming tube which is located at the front of the machine.

An optional motor-driven surface unwind wheel (power unwind) may be installed to drive the film roll as an assist to the driving of the two film transport belts. This option improves the unwinding process, especially when the film rolls are heavy.

The film enters a forming tube assembly. As it crests the shoulder (collar) on the forming tube, it is folded around the tube so that the end result is a length of film with the two outer edges of the film overlapping each other.

Bag Sealing and Cutting

The vertical seal bar, which is hot, moves forward and makes contact with the vertical overlap on the film, bonding the layers of film together.

A set of heated horizontal sealing jaws come together to make the top seal of one bag and the bottom seal of the next bag. While the sealing jaws are closed, the product that is being packaged is dropped down the middle of the hollow forming tube and filled into the bag.

This is a complete packaging process, you will get the perfect packaging finished product.

In addition to the power supply, the machine needs to be connected to the air source for

normal operation. So you need to have an air compressor. If your product needs to be

filled with nitrogen to ensure the freshness of the product, then you need to purchase a set

of nitrogen production equipment. In addition, our machines can also be equipped with

labeling machines, date coding machines, etc. to meet your production needs.

Hot Searches