- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1050*1100*1150mm

-

Weight:

-

900 KG

-

Marketing Type:

-

New Product 2023

-

Name:

-

centrifugal concentrator

-

Application:

-

Gold, gemstones, alluvial gold, vein gold ore, tin

-

Usage:

-

Mining Separatoion

-

Material:

-

Carbon Steel

-

Function:

-

Screening\separation\sorting\sieving

-

Advantage:

-

High Separation Efficiency

-

Capacity:

-

1-30tons

-

Feature:

-

Easy Maintenance\High Effecient

-

MOQ:

-

1Set

-

Feeding size:

-

0-6mm

Quick Details

-

Production Capacity:

-

1-200ton/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hiyoung

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1050*1100*1150mm

-

Weight:

-

900 KG

-

Marketing Type:

-

New Product 2023

-

Name:

-

centrifugal concentrator

-

Application:

-

Gold, gemstones, alluvial gold, vein gold ore, tin

-

Usage:

-

Mining Separatoion

-

Material:

-

Carbon Steel

-

Function:

-

Screening\separation\sorting\sieving

-

Advantage:

-

High Separation Efficiency

-

Capacity:

-

1-30tons

-

Feature:

-

Easy Maintenance\High Effecient

-

MOQ:

-

1Set

-

Feeding size:

-

0-6mm

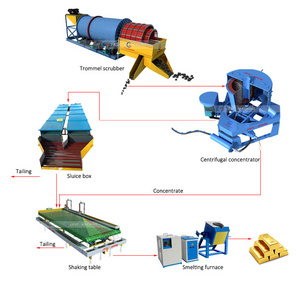

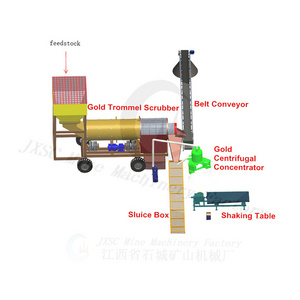

River Placer Gold Mining Safety Recovery Machine Equipment Process Plant Alluvial Small Scale

Product Description

Specification

|

Centrifugal concentrators(Pressure:0.15-0.2Mpa)

|

|

|

|

|

|

|

||||||

|

Equipment model

|

STL19

|

STL30

|

STL60

|

STL80

|

STL100

|

STL120

|

||||||

|

Handling capacity T/H (dry material)

|

0.25-0.30

|

2-8

|

15-20

|

30-40

|

40-60

|

60-90

|

||||||

|

Feed size mm

|

0-3

|

0-4

|

0-6

|

0-6

|

0-6

|

0-6

|

||||||

|

Concentration of feed ore %

|

0-50%

|

0-50%

|

0-50%

|

0-50%

|

0-50%

|

0—50%

|

||||||

|

Backflush volume T/H

|

1.5-2

|

4-6

|

10-15

|

17-25

|

40-60

|

70-80

|

||||||

|

Concentrate yield kg/time (1-3h)

|

2-3

|

10-20

|

30-40

|

60-70

|

70-80

|

110-120

|

||||||

|

Motor kw-grade

|

1.5-6

|

2.2-6

|

5.5-6

|

11-6

|

18.5-6

|

22-6

|

||||||

|

Cone speed

|

400

|

400

|

490

|

420

|

420

|

360

|

||||||

|

Pressure water M Pa

|

0.04—0.1

|

0.12

|

0.25

|

0.35

|

0.4

|

0.5

|

||||||

|

Dimension(m)

|

1.1/1.1/1.1

|

1.2/1.2/1.3

|

1.5/1.7/1.7

|

1.8/1.8/2.1

|

2.5/2.0/2.4

|

2.7/2.2/2.6

|

||||||

|

Equipped with water pump (sump pump)

|

Q:4-5m³/h;

H:40-50m;

|

Q:4-5m³/h;

H:40-50m;

|

Q:50m³/h;

H:40-50M;

|

Q:50m³/h;

H:40-50M;

|

Q:80-90m³/h;

H:40-50m;

|

Q:80-90m³/h;

H:40-50m;

|

||||||

|

Equipment quality T

|

0.145

|

0.4

|

1.1-1.4

|

2.6

|

2.8-3.2

|

3

|

||||||

Centrifugal Gold Concentrator is a High Efficiency Heavy Separation Equipment, the Principle is High Speed Rotation to Enlarge the Centrifugal Force of Feed Particles, and the Transverse Water Jet Flush the Light Particles out of the Concentration Cone, but the Heavy Particles Can Stay Because Its Larger Centrifugal Force, Light out and Heavy Stay to Achieve the Purpose of Separation. Due to Its Low Weight, the Settling Speed of Fine Particles is Slow, Which Makes It Difficult to Separate in Other Heavy Separation Equipment. when the Concentration Cone Works, It Can Generate 60 Times Gravitational Acceleration at the Inner Wall. when the Centrifugal Force Enlarge to 60 Times, the Centrifugal Force Difference Between Heavy Particles and Light Particles Will Increase Exponentially. Therefore, Centrifugal Gold Concentrator Utilizes It to Separate Heavy Particles and Light Particles.

▶ Product Details

▶ Factory Real Shot

▶ Recommend Products

Hot Searches