- Product Details

- {{item.text}}

Quick Details

-

Tolerance:

-

±3%

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

Langford, Langford

-

Model Number:

-

Q235 Q345 Q215

-

Application:

-

Beam, bridges, construction ,communications tower

-

Product name:

-

aluminium profiles extrusion

-

Surface treatment:

-

Anodized

-

Color:

-

Customized

-

Thickness:

-

0.4 mm thickness above

-

Certification:

-

ISO9001

-

Supply Ability:

-

200000 Ton/Tons per Year

-

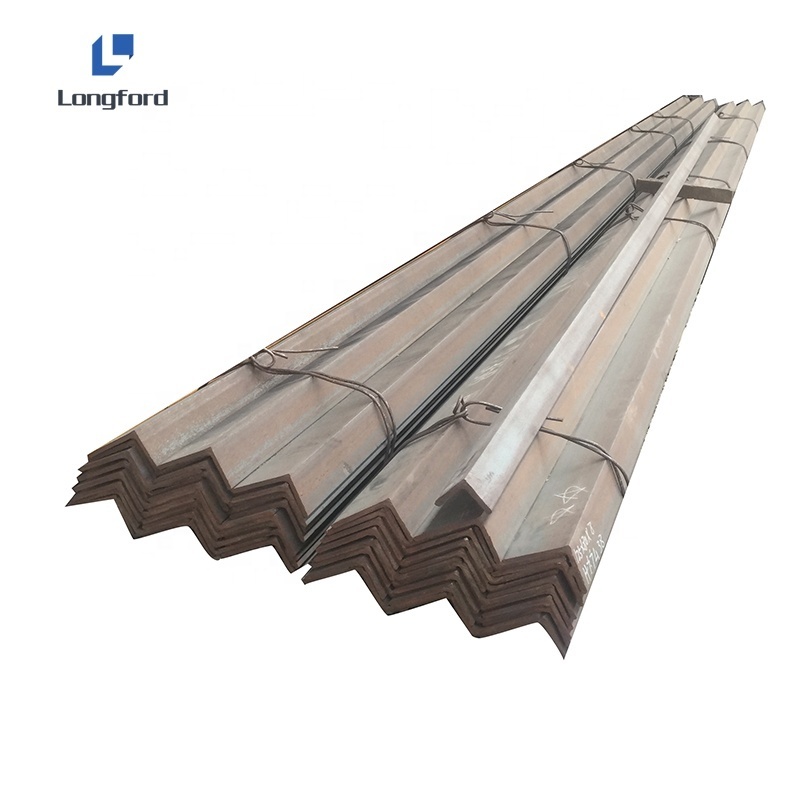

Packaging Details:

-

Metal pallet or depend on customer special requirement.

-

sample lead time:

-

5-7 days

-

Country of origin:

-

Tianjin, China

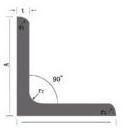

Quick Details

-

Standard:

-

AiSi

-

Grade:

-

Q195-Q420 Series

-

Type:

-

Equal

-

Tolerance:

-

±3%

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

Langford, Langford

-

Model Number:

-

Q235 Q345 Q215

-

Application:

-

Beam, bridges, construction ,communications tower

-

Product name:

-

aluminium profiles extrusion

-

Surface treatment:

-

Anodized

-

Color:

-

Customized

-

Thickness:

-

0.4 mm thickness above

-

Certification:

-

ISO9001

-

Supply Ability:

-

200000 Ton/Tons per Year

-

Packaging Details:

-

Metal pallet or depend on customer special requirement.

-

sample lead time:

-

5-7 days

-

Country of origin:

-

Tianjin, China

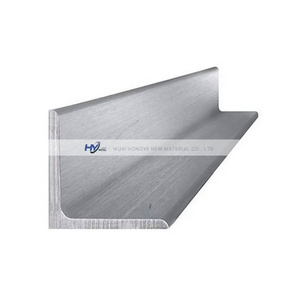

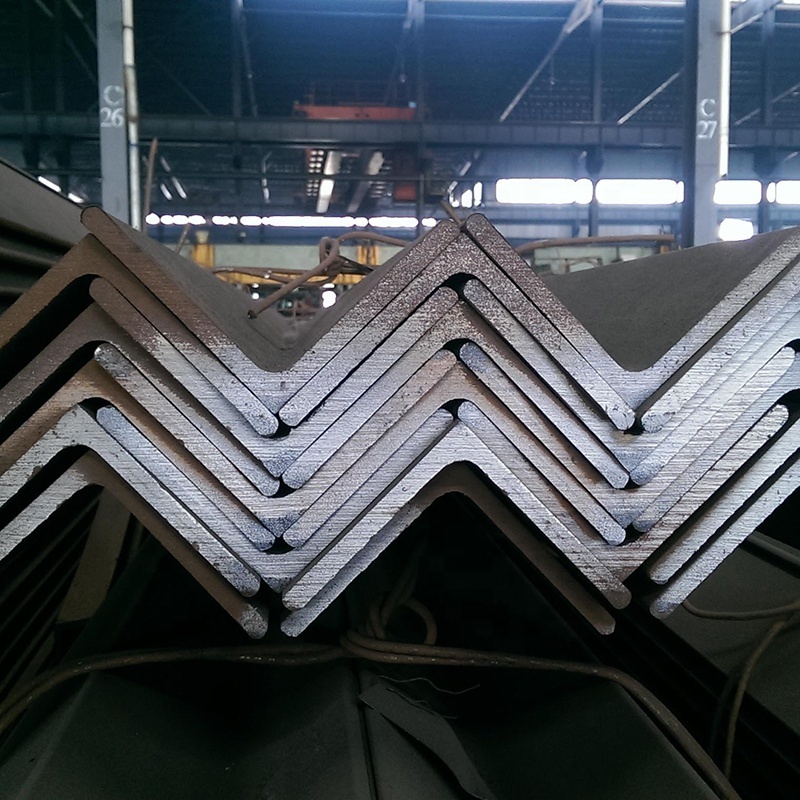

Products Description

Title goes here.

Angle steel is a carbon structural steel for construction. It is a section steel with a simple section. It is mainly used for metal components and the frame of factory buildings. In use, it requires good weldability, plastic deformation performance and certain mechanical strength. The raw material billets for the production of angle steel are low-carbon square billets, and the finished angle steel is delivered in a hot-rolled, normalized or hot-rolled state.

Performance

1 The profile shape is manufactured from hot rolled strip. During the forming process, all surface areas

are mechanically and chemically cleaned to the equivalent of AS1627.4 Class 3, and then coated by an

in-line hot-dip process.

2 The durability performance is influenced by micro-environments which vary from site to site. In highly corrosive environments it is recommended that a suitable barrier coating, (eg. paint or

powder coating) be applied over the galvanized surface, and that the application of such coating be fully

in accordance with the supplier’s recommendations with regard to surfacepretreatment, application, curing

and maintenance of the coating.

Hot Searches