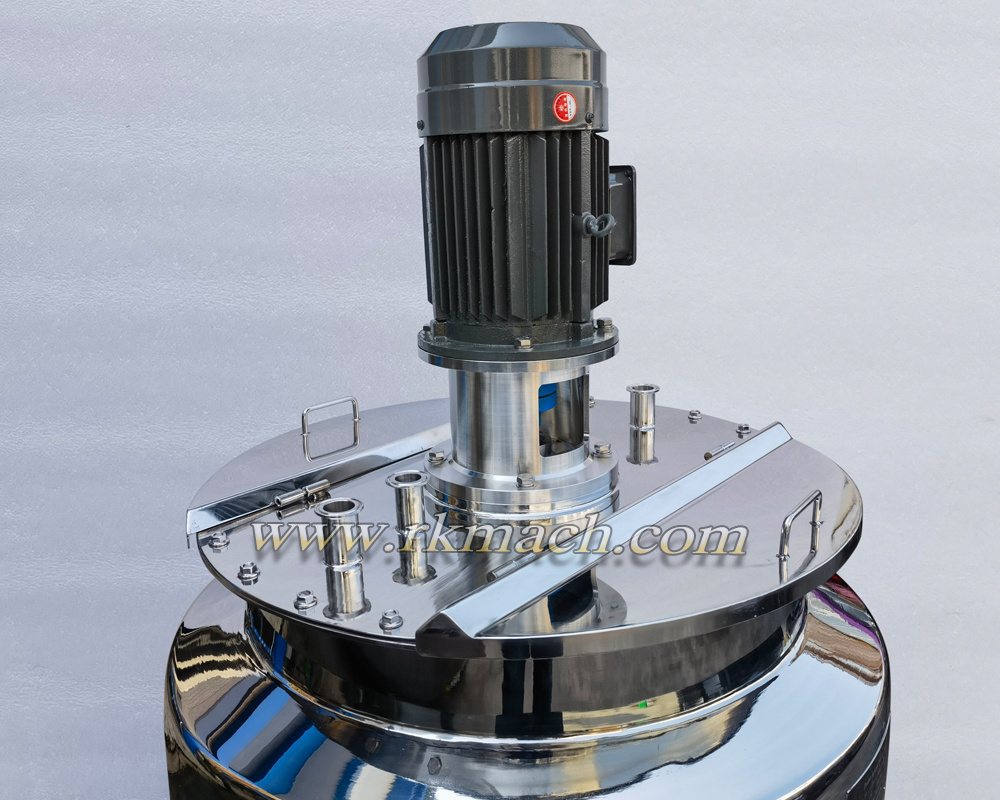

Material: SS304 / SS316L

Mixing speed: 2800rpm / 3600rpm

this mixer can be 2800rpm or 3600rpm. power supply 220V 60Hz 3phase or 380V 50Hz 3 phase.

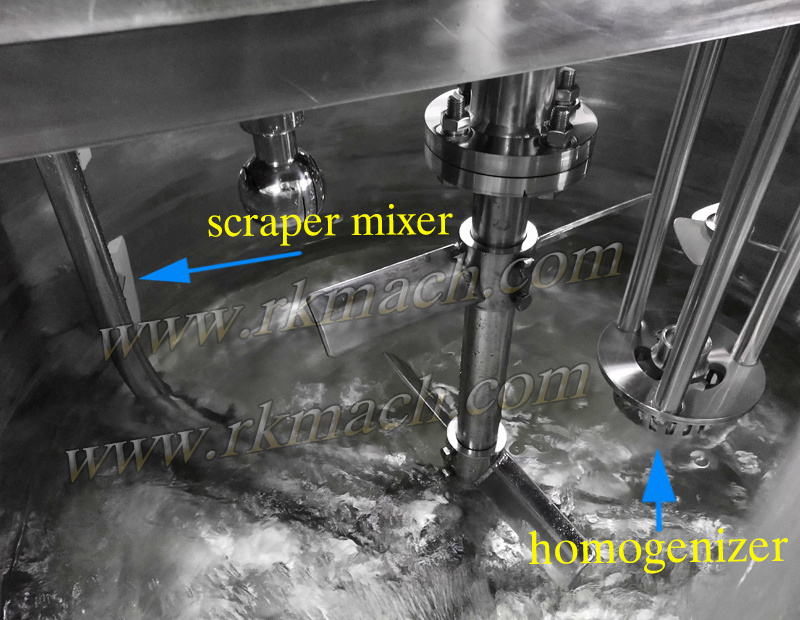

high shear mixer. homogenizer mixer, homo-mixer, emulsifier, High Shear Mixer ,Bottom Entry Emulsifying Mixer