- Product Details

- {{item.text}}

Quick Details

-

Head Code:

-

round

-

Place of Origin:

-

China

-

Product name of dished head:

-

Carbon steel stainless steel hemispheres dish head end cap

-

Application of end cap:

-

Pressure vessel or tank

-

Body material:

-

S316 Q235B

-

Color:

-

Customzied Color

-

Size:

-

Customized Size

-

Surface treatment:

-

Sand Blasting /Pickling

-

Standard:

-

ASME

-

Test:

-

Pt,RT,Ut,Mt.Et

-

Certificate:

-

ISO 9001

Quick Details

-

Material:

-

Stainless Steel/Carbon Steel

-

Technics:

-

Casting

-

Shape:

-

Hemispherical

-

Head Code:

-

round

-

Place of Origin:

-

China

-

Product name of dished head:

-

Carbon steel stainless steel hemispheres dish head end cap

-

Application of end cap:

-

Pressure vessel or tank

-

Body material:

-

S316 Q235B

-

Color:

-

Customzied Color

-

Size:

-

Customized Size

-

Surface treatment:

-

Sand Blasting /Pickling

-

Standard:

-

ASME

-

Test:

-

Pt,RT,Ut,Mt.Et

-

Certificate:

-

ISO 9001

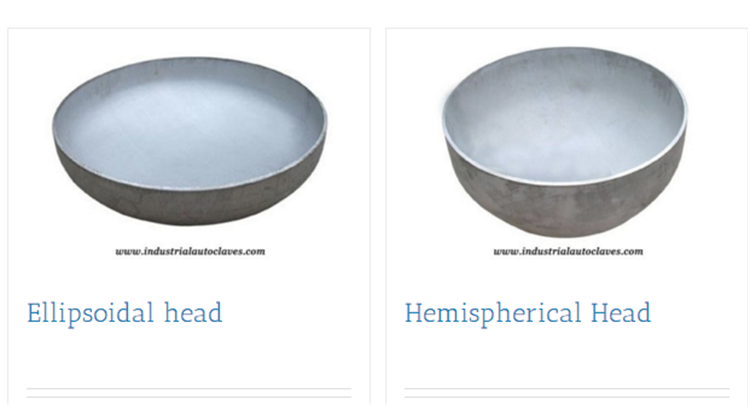

Hemispherical Tank Head (also called hemispherical heads or hemispherical dish ends) is widely applied to make pressure tanks to storage liquids and gasses. Our asme hemispherical head is often made with carbon steel, stainless steel, austenitic and non ferritic metals that can be cold worked. Hemispherical is the ideal shape for development of hemispherical dish end, because the pressure in the vessel is divided equally across the surface of the head. The radius (Ri) of the head equals the radius of the cylindrical part of the vessel. This type of hemispherical tank heads or hemispherical dish ends are made in most popular sizes and thicknesses.

The smaller diameter of the hemispherical head can be the overall compression molding, but the larger diameter because of its large depth, the overall compression is difficult, it is necessary to use a number of the same sizes of the trapezoidal ball and the top of the center of a round spherical plate ball crown made of welding.

- Materials: Ferritic, austenitic and non ferritic metals that can be cold worked.

- Fabrication Method: cold dishing and flanging or pressing.

- Dimensions: up to 8,000 mm diameter and 50mm thickness.

- Edge preparation: according to your requirement.

- Approval: ASME.

- Inspections: by TÜV or other inspection companies.

We use the most advanced production line equipment, large punching machine, large rolling machine, CNC automatic welding machine, vacuum unit, CNC spinning shut, closed end equipment, automated heat treatment equipment, CNC winding equipment, electrostatic spraying equipment, helium mass spectrometer leak detector, spectrum analyzer, automatic ultrasonic flaw detector, X-ray detection machine, universal testing machine, impact testing machine and other sound sophisticated detection equipment.