- Product Details

- {{item.text}}

Quick Details

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Certification:

-

CE,&ISO

-

Feeding way:

-

Automatic

-

Function:

-

Reducing&Expanding

-

Application:

-

automobiles, furniture, exhaust pipe, vessel

-

Raw Material:

-

Any metal pipe

-

Cooling:

-

Water

-

Control:

-

Single Chip

-

Quality:

-

High

-

Product name:

-

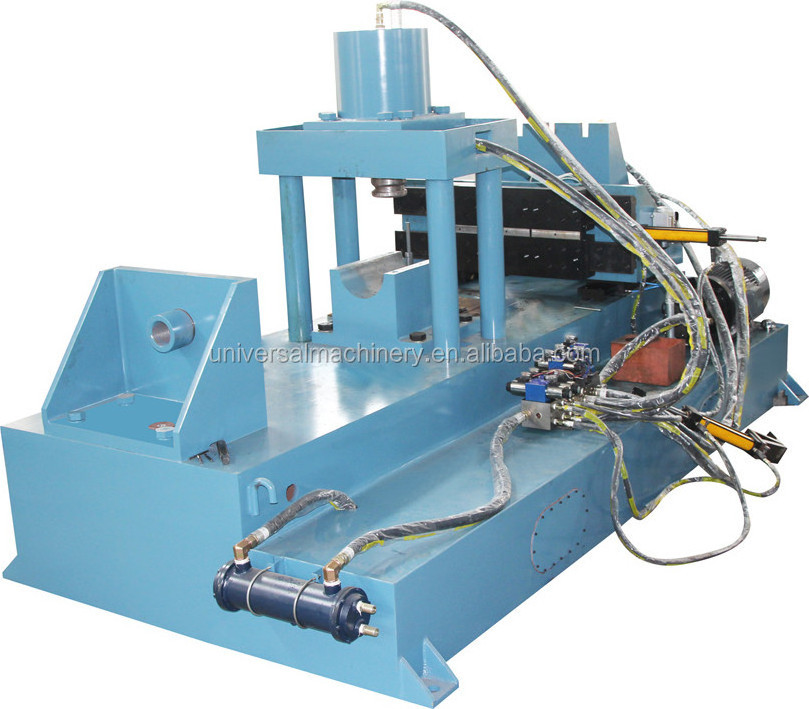

Tube End Swaging Machine

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

UM

-

Weight (KG):

-

2500

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Certification:

-

CE,&ISO

-

Feeding way:

-

Automatic

-

Function:

-

Reducing&Expanding

-

Application:

-

automobiles, furniture, exhaust pipe, vessel

-

Raw Material:

-

Any metal pipe

-

Cooling:

-

Water

-

Control:

-

Single Chip

-

Quality:

-

High

-

Product name:

-

Tube End Swaging Machine

|

Parameters |

UM-168NC |

|

Max processing capability |

Max Φ168mm |

|

Max processing length |

250mm(Can made to order) |

|

Main cylinder max output |

30T |

|

Motor power |

15Kw |

|

Oil pressure |

20MPa |

|

Size |

4300×1000×1800mm |

|

Gross weight |

2500 kg |

Notice: we have one station, two stations, three stations and multi stations and different models of Pipe End Forming Machine, please inform us your specific requirements, then we will recommend you the right model.

Microcomputer control (NC), convenient operation and flexible settings.

Powerful hydraulic clamping and customized, specially designed clamp dies make the clamp firm enough without damaging the pipe surface.

Forming is driven by hydraulic. The forming moulds are designed by the professional engineers with much experience. Precise processing makes the moulds more delicate and accurate.

Adopting the premium linear slide rail, providing stable propulsion.

The hydraulic system is all assembled by the imported and premium components, which makes the system more powerful and stable.

Equiped with all kinds of forming moulds, for tube end forming like swaging , expanding, contracting, reducing, making flange and other special formings .

Hydraulic cooling system to ensure the equipment long-time work stably under the high temperature .

Big Diameter Tube End Swaging Machine for Swaging Reducing Expanding Flanging

Big Diameter Tube End Swaging Machine for Swaging Reducing Expanding Flanging

Big Diameter Tube End Swaging Machine for Swaging Reducing Expanding Flanging

1. Reply your inquiry within 12 working hours.

2. Experienced engineer instruct and sales communicate with you in fluent English.

3. According to work pieces specifications, heating requirements, propose best solutions,also reference your ideas.

4. Machine details and working video link for your reference

5. Competitive price with high quality,compare with the same industry.

6. Production: strict quality standard, to produce machine and induction coils.

7. Debugging machine and only good machine will be sent.

8. Tracking goods shipping and provide bill of lading,invoice,packing list and other documents what you need

9. Provide install and technology instruction by sending drawings, email, or telephone,video.

10. If you need, will arrange one engineer to your place, instruct install machine and training operators.

11.Excess warranty period (24 months warranty), you can buy the spare parts from us with special discount price.

12.Provide long-terms technical support, supply whole life after sell service.

WhatsApp: 008615995988626

WeChat: UCMLIU

Skype:janeliujingjing

QQ:3355788956

Mail:bendermachine at hotmail.com

Mobile:0086-15995988626

Phone:0086-51258618603

We are online for 24hours, please contact us freely!