- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Covestro/Makrolon

-

Material:

-

100% Vrigin PC Material

-

Type:

-

Engineering Resin

-

Package:

-

25Kg/Bag

Quick Details

-

color:

-

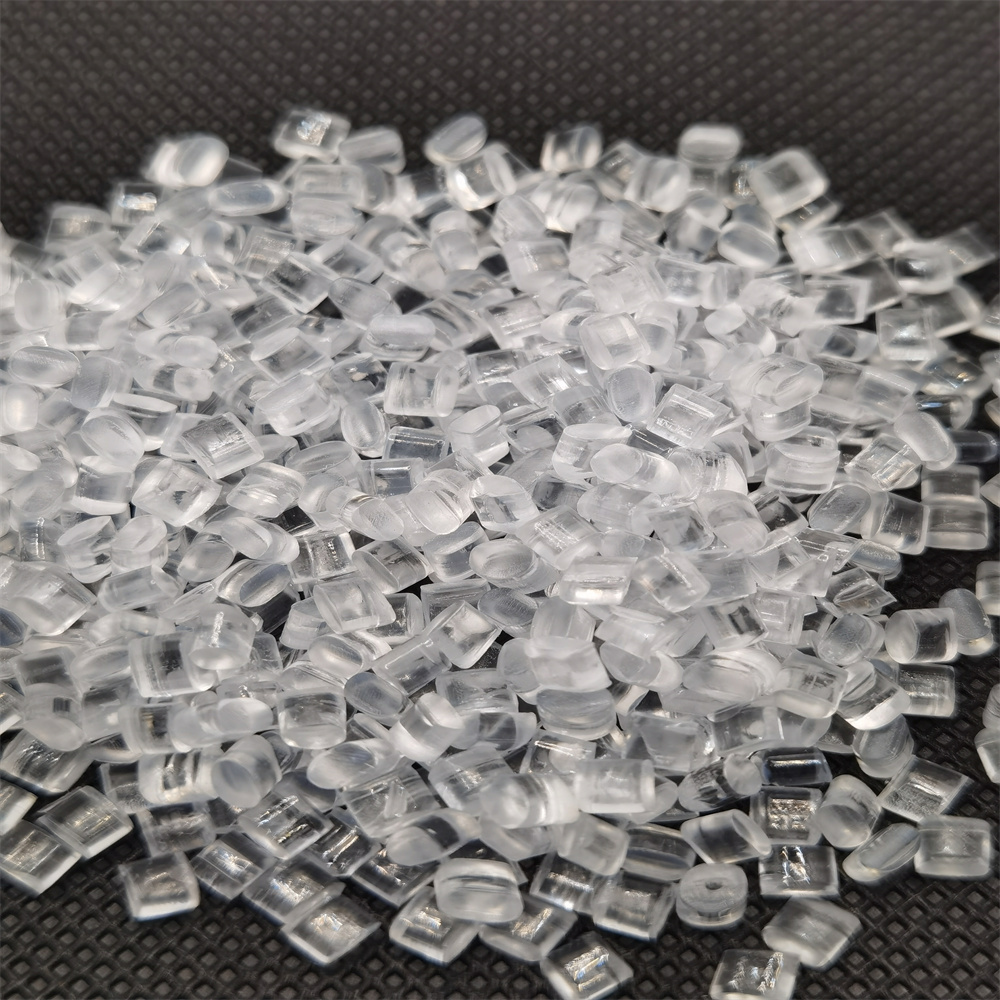

Transparent

-

Shape:

-

Granules

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Covestro/Makrolon

-

Material:

-

100% Vrigin PC Material

-

Type:

-

Engineering Resin

-

Package:

-

25Kg/Bag

Covestro Makrolon Polycarbonate

Place of Origin:China

Brand Name:Covestro/Makrolon

Model Number:6555

Featured:Flame retardant, Transparent

Quality:High-quality

Application:General

Keywords:Covestro 6555/ Makrolon 6555/ Covestro Makrolon 6555

Material:Polycarbonate, 100% Vrigin PC Material

Brand:Covestro makrolon

Brand Name:Covestro/Makrolon

Model Number:6555

Featured:Flame retardant, Transparent

Quality:High-quality

Application:General

Keywords:Covestro 6555/ Makrolon 6555/ Covestro Makrolon 6555

Material:Polycarbonate, 100% Vrigin PC Material

Brand:Covestro makrolon

Product Description

Makrolon® 6555

MVR (300 °C/1.2 kg) 10 cm³/10 min; flame retardant; UL 94V-0/3.0 mm; medium viscosity; easy release

MVR (300 °C/1.2 kg) 10 cm³/10 min; flame retardant; UL 94V-0/3.0 mm; medium viscosity; easy release

Rheological properties

|

Property

|

|

Test Condition

|

Unit

|

Standard

|

typical Value

|

|

|

C

|

Melt volume-flow rate

|

300 °C/ 1.2 kg

|

cm³/10 min

|

ISO 1133

|

10

|

|

|

|

Melt mass-flow rate

|

300 °C/ 1.2 kg

|

g/10 min

|

ISO 1133

|

10

|

|

|

C

|

Molding shrinkage, parallel

|

60x60x2 mm/ 500 bar

|

%

|

ISO 294-4

|

0.7

|

|

|

C

|

Molding shrinkage, normal

|

60x60x2 mm/ 500 bar

|

%

|

ISO 294-4

|

0.75

|

|

|

|

Molding shrinkage, parallel/normal

|

Value range based on general

practical experience |

%

|

b.o. ISO 2577

|

0.6-0.8

|

|

Mechanical properties (23 °C/50 % r. h.)

|

Property

|

|

Test Condition

|

Unit

|

Standard

|

typical Value

|

|

|

C

|

Tensile modulus

|

1 mm/min

|

MPa

|

ISO 527-1,-2

|

2400

|

|

|

C

|

Yield stress

|

50 mm/min

|

MPa

|

ISO 527-1,-2

|

66

|

|

|

C

|

Yield stress

|

50 mm/min

|

%

|

ISO 527-1,-2

|

6.2

|

|

|

C

|

Nominal strain at break

|

50 mm/min

|

%

|

ISO 527-1,-2

|

>50

|

|

|

|

Stress at break

|

50 mm/min

|

kJ/m²

|

ISO 527-1,-2

|

70

|

|

|

|

Stress at break

|

50 mm/min

|

kJ/m²

|

b.o. ISO 527-1,-2

|

130

|

|

|

C

|

Tensile creep modulus

|

1 h

|

MPa

|

ISO 899-1

|

2200

|

|

|

C

|

Tensile creep modulus

|

1000 h

|

MPa

|

ISO 899-1

|

1900

|

|

|

|

Flexural modulus

|

2 mm/min

|

MPa

|

ISO 178

|

2400

|

|

|

|

Flexural strength

|

2 mm/min

|

MPa

|

ISO 178

|

98

|

|

|

|

Flexural strain at flexural strength

|

2 mm/min

|

%

|

ISO 178

|

7.1

|

|

|

|

Flexural stress at 3.5 % strain

|

2 mm/min

|

MPa

|

ISO 178

|

74

|

|

|

C

|

Charpy impact strength

|

23 °C

|

kJ/m²

|

ISO 179/1eU

|

N

|

|

|

|

Charpy impact strength

|

-60 °C/3mm

|

kJ/m²

|

ISO 179/1eU

|

N

|

|

|

|

Charpy notched impact strength

|

23 °C/3mm

|

kJ/m²

|

ISO 21305/based on ISO 180/A

|

70P(C)

|

|

|

|

Charpy notched impact strength

|

-30 °C/3mm

|

kJ/m²

|

ISO 21305/based on ISO 180/A

|

14C

|

|

|

|

Izod notched impact strength

|

23 °C/3mm

|

kJ/m²

|

ISO 21305/based on ISO 180/A

|

65P(C)

|

|

|

|

Izod notched impact strength

|

-30 °C/3mm

|

kJ/m²

|

ISO 21305/based on ISO 180/A

|

12C

|

|

|

C

|

Puncture impact properties - maximum force

|

23 °C

|

N

|

ISO 6603-2

|

5400

|

|

|

C

|

Puncture impact properties - maximum force

|

-30 °C

|

N

|

ISO 6603-2

|

6300

|

|

|

C

|

Puncture energy

|

23 °C

|

J

|

ISO 6603-2

|

60

|

|

|

C

|

Puncture energy

|

-30 °C

|

J

|

ISO 6603-2

|

65

|

|

|

|

Ball indentation hardness

|

|

N/mm²

|

ISO 2039-1

|

115

|

|

About Polycarbonate

"Polycarbonate" is made of bisphenol A, which is a polymer material of polycarbonate. It has excellent high transparency and heat resistance temperature, as well as the highest impact strength of thermal plasticity resin, and good formability

"Polycarbonate" is the best material of choice for replacing metal supplies for automobile components, business machines, home appliances,electronic parts, food appliances, medical equipment and communication equipment.

"Polycarbonate" is the best material of choice for replacing metal supplies for automobile components, business machines, home appliances,electronic parts, food appliances, medical equipment and communication equipment.

Hot Searches