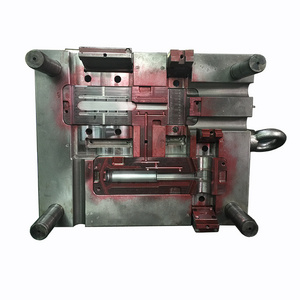

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

bp_502

-

Product Name:

-

Plastic Injection Mold

-

Application:

-

Household Product Mold

-

Surface treatment:

-

Polish. Etched. Texture

-

Mould material:

-

P20/718/738/NAK80/S136/2738/2316

-

Color:

-

Customized Colors

-

Keyword:

-

Mould Maker

-

Plastic material:

-

PVC/PA66/PC/PE/POM/PMMA/ABS/TPU/TPE/PE/PP.ETC

-

Mold Base:

-

LKM.HASCO.DME.45#.etc

-

Cavity:

-

Single Cavity\ Multiple Cavity

-

Design software:

-

UG PROE CATIA SOLIDWORK CAD

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

billow peak

-

Model Number:

-

bp_502

-

Product Name:

-

Plastic Injection Mold

-

Application:

-

Household Product Mold

-

Surface treatment:

-

Polish. Etched. Texture

-

Mould material:

-

P20/718/738/NAK80/S136/2738/2316

-

Color:

-

Customized Colors

-

Keyword:

-

Mould Maker

-

Plastic material:

-

PVC/PA66/PC/PE/POM/PMMA/ABS/TPU/TPE/PE/PP.ETC

-

Mold Base:

-

LKM.HASCO.DME.45#.etc

-

Cavity:

-

Single Cavity\ Multiple Cavity

-

Design software:

-

UG PROE CATIA SOLIDWORK CAD

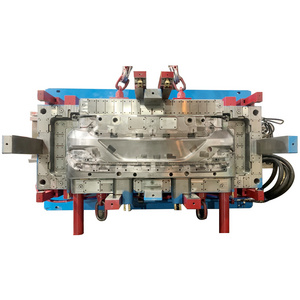

China Custom ABS Plastic Shell Molding Parts Injection Mold Manufacture Factory for Household Appliances

molds parameter

| Company Name | Zhongshan billowpeak Technology Co., Ltd. |

| Brand | bp tech |

| Main Product | Precision mold, Injection mold, Extrusion mold, Injection plastic products, die cast mold...etc |

|

Injection Machine

(Double Color)

|

88T, 90T, 120T, 168T, 200T,250T,380T,420T,600T,800T,1000T,1200T,1500T,2200T,2800T,3000T |

| Application | Electronics industry, Medical industry, Home appliance industry, Aerospace, Shipbuild industry, Household goods, Automobile industry, Machinery industry,Machinery industry,Semicoductor industry,Food processing, Robot industry,etc |

| Mould Base | LKM Standard,DME Standard,HASCO Standard,FUTABA Standard,Self-made Standad ,etc. |

| Mould Material | 718H/738H/718/738/NAK80/S136/S136H/2738/2316/H13/P20/2344ESR/8407/SKD |

| Moud Precision | +/-0.01mm |

| Mould Life | 100K-1000K shots |

| Mould Cavity | Single cavity, multi-cavity |

| Runner System | Hot runner and cold runner |

| Manufacturing Equipments | Imported CNC equipment, EDM machines, Imported mirror wire cutting machines, High-speed precision engraving machines, Laser cutting machines, Sodick slow threading machines, Precision grinders, Plastic injection molding machines,Double color injection machines,etc |

| Product Drawings | 2D Drawings, 3D Drawings, product samples, or the size of the multi-angle pictures |

| Quanlity System | ISO 9001, RoHS Srandard, etc |

| Plastic Raw Material | Nylon6, Nylon66, PA6, PA66, PA6+GF, ABS, ABS+GF, ABS+PC, POM(Derlin), PP, PE, PC, PVC, PMMA(Acrylic),TRU,EPDM,NBR, Silicon,UHMWPE,PVDF,PTFE,ETFE,PFA,PCTFE,FEP,PVF,PSF, PEI, PSU,PPSU, PPS, PEEK, PAI, PI, PBI,etc. |

| Color | white,black,gray,green,blue,pink,yellow,golden,natural color and custom color,etc |

| Surface Treatment Tech | Polishing,Painting,Electroplate,Anodizing, Brushing, Silk Screening,Water Transfering, Leather Covering,Texture, Sanblasting,Gilding, UV Painting… |

FAQ

Q1. How Fast Can I Get My Parts?

A1. We can fulfill orders quickly, but lead times depend on a few factors, such as the manufacturing process, order quantity, and part complexity. CNC machined parts can take as little as five days, 3D printed parts can take as little as three days, while moldings

made via rapid tooling can take as little as 7 days.

made via rapid tooling can take as little as 7 days.

Q2. What Is The Accuracy Of The Products Processed By The Drawings?

A2. Different equipment has different accuracy, generally between 0.05-0.1 mm.

Q3. What Craftsmanship Do You Have For Frocessing Accessories?

A3.According to different products, different processes are used, such as machining, extrusion, injection molding, etc.

Q4. What Areyour Processing Equipment?

A4. CNC machining center, CNC lathe, milling machine, engraving machine, injection molding machine,extruder, molding machine.

Q5. Can You Help Assembling The Product After It Is Made?

A5. It's okay .

Q6. What Certifications Or Qualifications Does Your Company Have?

A6. Our company’s certificates are:CE, ISO, ROHS, product patent certificates, etc.

Our manufacture parts to a high standard, no matter the project or the customer.

Q7. Can Injection Products Be Surface Treated? What Are The Surface Treatments?

A7. It is ok. Surface treatment: spray paint, silk screen,electroplating, etc.

Q8.

I Want To Protect My IP. Are My Designs Secure?

A8.We values privacy and security with the utmost seriousness and will happily sign a non-disclosure agreement (NDA) at your request,giving you peace of mind about your intellectual property.

Hot Searches