- Product Details

- {{item.text}}

Quick Details

-

Max working pressure:

-

20Mpa

-

Max output:

-

10kg/min

-

Max heating hose length:

-

90M

-

Pneumatic source:

-

0.6-0.9Mpa 1m3/min

-

Gross weight:

-

190kg

-

Weight:

-

190kg

-

Power:

-

14kw

Quick Details

-

Place of Origin:

-

Shandong, China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

Ratio of raw material:

-

1:1

-

Max working pressure:

-

20Mpa

-

Max output:

-

10kg/min

-

Max heating hose length:

-

90M

-

Pneumatic source:

-

0.6-0.9Mpa 1m3/min

-

Gross weight:

-

190kg

-

Weight:

-

190kg

-

Power:

-

14kw

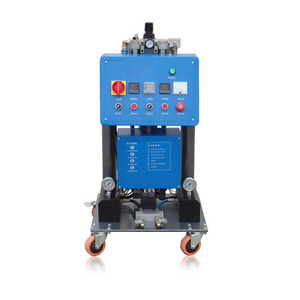

JHBW-AH3000 spraying polyurethane foam machine

1. Polyurethane spray on wall & roof,

2. Polyurea spray for waterprrof & anticorrosion,

3. Construction seam filling,

4. Cold storage spray insulation,

5. Tank and pipe spray insulation,

6. Polyurethane foam for package cushioning,

7. Car roof spray insulation,

8. Highway, railway, automobile, watercraft, mining petroleum, electrical industry, food industry etc.

| Specifications: JHBW-AH3000 | |

| The ratio of raw material | 1:1 |

| Viscosity range of raw material | 200-1000CPS(under working temperature) |

| Max working pressure | 20MPa |

| Max fluid temperature | 80°C |

| Max output | 10kg/min |

| Max heating hose length | 90m |

| Heater power | 4500W×2 |

| Drive model | Full pneumatic |

| Spray gun clean | Self-clean by air |

| Voltage (Optional) | Customized |

| Pneumatic source | 0.6-0.9Mpa 1m³/min |

|

Standard Configuration:

|

|

|

JHBW-AH3000 mainframe

|

1 set

|

|

JHBW-P2 spray gun

|

1 pc

|

|

Transfer pump

|

2 pcs

|

|

Heated hose (Standard)

|

15m

|

|

Max hose length (Optional)

|

90m

|

|

Transfer pump hose

|

2 pcs

|

|

Air pipe

|

1 set

|

|

Spare parts and tools

|

1 set

|

|

Transport Parameter:

|

|

| Package size (L×W×H) | 110×80×145cm |

| Net weight/Gross weight | 160kg/190kg |

1. JHBW-AH3000 has passed CE, ISO9001 Quality Management system certification, completely independent intellectual property design and production, has declared a number of national invention patents.

2. This equipment low failure rate, easy to move, easy to operate, heating faster, spraying evenly, save 10% material.

3. The flat-type booster pump has the perfect coaxial structure design, minimizing the wear of the seal ring. The two-way pressurization design minimizes the pressure fluctuation, and the spraying effect is more stable than the traditional booster pump.

4. Equipped with isocyanate anti crystallization & lubrication device, the circulating lubricating fluid can take away the leaking isocyanate or the magazine at any time, the pump shaft always infiltrates in the lubricating fluid, avoids the isocyanate crystallization.

5. The cylinder is equipped with the prevention of cryogenic icing device, so that the equipment can still work normally under low temperature condition.

6. Accurate counter allows you to accurately calculate the amount of raw material.

7. The heater uses a special frequency control device, the temperature sensor real-time acquisition of temperature signals, so that the heater is in good control.

8. This equipment has the overheating protection device, simultaneously uses the famous import component, causes the equipment performance to be more stable and reliable.

9. Equipped with emergency switching system, can be the quickest response to emergency situations.

10. Installation of front filter, can effectively filter impurities in raw materials, reduce the occurrence of gun blocking.

Jinan JingHuabangwei Polyurethane Equipment Co., Ltd

Founded in 2011, Jinan JingHuabangwei Polyurethane Equipment Co., Ltd. is a manufacturer of polyurethane and polyurea equipment integrating R&D, production, sales and after-sales maintenance services. The company has strong R&D and production experience. The machine has passed the national CE certification and ISO 9001 certification, and the quality of the products is guaranteed. At present, the company has developed into a professional manufacturer of polyurethane and polyurea equipment with global competitiveness and core competitiveness in more than 80 countries and regions around the world.

The company specializes in the research and development and production of polyurethane spraying, filling equipment, polyurea spraying equipment. On this basis, the products are divided into pneumatic vertical, horizontal equipment, hydraulic equipment and other professional products suitable for different industries. Products are suitable for: construction, building materials, automotive, environmental protection, waterproof, anti-corrosion, light industry, chemical, electronic information, transportation, equipment, textile, medical, sports, defense, aerospace, thermal, biotechnology, warehousing, transportation, Packaging, handicrafts and many other industries.

Over the years, we have gathered a group of outstanding R&D and mechanical design talents. Based on our accumulated experience, we have created polyurethane and polyurea equipment suitable for modern production and construction processes. All employees of Jinghua Bangwei adhere to the corporate philosophy of “Quality First, Customer First”, regard product quality as the life of the company, and strive to build a world famous brand!

Customer case:

1. We packed the machine in the plywood carton, to make sure it safety transportation.

2. We support shipping by ocean, air, truck and express, please consult the shipping cost.

3. One year warranty, any broken parts will be sent by express free,

4. We offer 24 hours online sevices (Skype, WhatsApp, WeChat, Telphone),

5. We have two days free training in the factory,

6. Free video training and maintenance,

7. Engineers on-site service (some countries and regions).

8. For more information about the machine, please contact:

WhatsApp/WeChat/Skype: +86-133-953-11055