- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3550*2200*5650mm

-

Weight:

-

1300 KG

-

Marketing Type:

-

Hot Product 2024

-

Mobility:

-

yes

-

torque:

-

7500 N.m

-

stroke of power head:

-

3500 mm

-

Working size:

-

3550*2200*5650mm

-

Lateral movement:

-

900mm

-

system pressure:

-

20Mpa

-

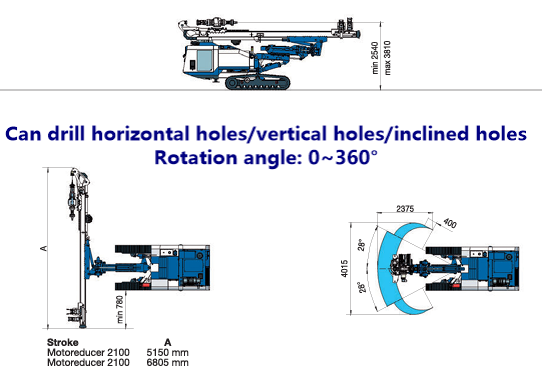

Boom pitch:

-

Up and down total 60

-

Boom swing angle:

-

Left and right total 70

-

Skid swing angle:

-

Up and down total100

-

Skid pitch:

-

Up and down total100

-

weight:

-

4800Kg

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DH

-

Voltage:

-

by customer

-

Dimension(L*W*H):

-

3550*2200*5650mm

-

Weight:

-

1300 KG

-

Marketing Type:

-

Hot Product 2024

-

Mobility:

-

yes

-

torque:

-

7500 N.m

-

stroke of power head:

-

3500 mm

-

Working size:

-

3550*2200*5650mm

-

Lateral movement:

-

900mm

-

system pressure:

-

20Mpa

-

Boom pitch:

-

Up and down total 60

-

Boom swing angle:

-

Left and right total 70

-

Skid swing angle:

-

Up and down total100

-

Skid pitch:

-

Up and down total100

-

weight:

-

4800Kg

Product Description

Anchor drilling rig, in some places, ,is also known as anchor rod drilling machine. This hydraulic anchor drill machine. is a kind of necessary, .engineering machinery in infrastructural project. lt is a drilling tool in coal mine roadway for supporting anchor rod.

Anchor rig has outstanding advantages, such. as improving supporting effect, reducing the cost,speeding up the lane, lessening auxiliary traffic, decreasing labor intensity, increasing the utilization rate, of roadway section. Anchor drilling rig is the key equipment to rock bolting. If influences the quality of bolt support, such as the orientation of the bolt hole, the depth' accuracy, the diameter and anchor installation quality. It also affects the personal safety of the operator, labor intensity, work conditions, etc.

Anchor rig has outstanding advantages, such. as improving supporting effect, reducing the cost,speeding up the lane, lessening auxiliary traffic, decreasing labor intensity, increasing the utilization rate, of roadway section. Anchor drilling rig is the key equipment to rock bolting. If influences the quality of bolt support, such as the orientation of the bolt hole, the depth' accuracy, the diameter and anchor installation quality. It also affects the personal safety of the operator, labor intensity, work conditions, etc.

drilling efficiency

2. Serialized products have different models, different capabilities, and multiple choices to meet the needs of different

customers.

3. Power head can be mechanically / hydraulically shifted. Suitable for various drilling methods such as down-the-hole hammer,heel pipe, full casing and alloy rotation

4.The drilling rig is equipped with a hydraulic clamping shackle device and an automatic shackle, which reduces auxiliary time and labor intensity.

6. The crawler chassis equipped with a turning device on the car makes the whole machine move and find holes more conveniently and quickly.

Specification

|

Model

|

DH-150

|

||

|

Drill diameter (mm)

|

φ150~φ250

|

||

|

Diameter(mm)

|

Single: 400-600 double: 600-1200 triple: 800-1600

|

||

|

Drill depth (m)

|

130~170

|

||

|

Pipe diameter (mm)

|

φ73, φ8, φ10, φ114/φ127, φ133, φ140, φ146

|

||

|

Drilling angle (° )

|

0~90

|

||

|

Boom, lift.(mm)

|

NO

|

||

|

Gyrator Output torque (N. m)

|

7500

|

||

|

Gyrator impact(J)

|

NO

|

||

|

Gyrator frequency(min-1)

|

NO

|

||

|

Gyrator Stroke (mm)

|

3400

|

||

|

process(mm)

|

900

|

||

|

Gyrator lift (kN)

|

70

|

||

|

Gyrator lifting speed (m/min)

|

0~5(Adjustable),7, 23, 30

|

||

|

Gyrator pressure (kN)

|

36

|

||

|

Gyrator Feeding speed (m/min)

|

0~10(Adjustable), 14, 46, 59

|

||

|

Input power (kW)

|

55+18.5

|

||

|

Transport dimensions (L*W*H) mm)

|

5400×2100×2000

|

||

|

Weight (t)

|

6000

|

||

Details Images

Customer Photos

Our Services

1.Whole process guidance

With more than 15 years of service experience, we will spare no effort to provide support in selecting

equipment, customizing production lines, improving supply chain, and post-optimization etc.

2.Provide a full set of construction method and equipment training Provide design and construction solutions in terms of cost budget / progress improvement / quality control / safety management.

3.After-sales service system

Fully track the service system, focus on customer needs, first-class speed, skills, attitude, and provide support for customer

4.Support customization

Relying on our powerful flexible production line, we can give you the right to fully choose the mold,

drive method, accessories upgrade, shell material, appearance color and Logo etc.

5.Extensive spare parts service

The spare parts warehouse of more than 50,000 square meters can meet the timely replacement and supplement of any wearing parts.

6.Support sea, land and air transportation We can ship products to every corner of the world. If you need, we also support a series of tedious tasks such as customs clearance and tail end delivery.

Hot Searches