7.Square steel 8.Adjustment device

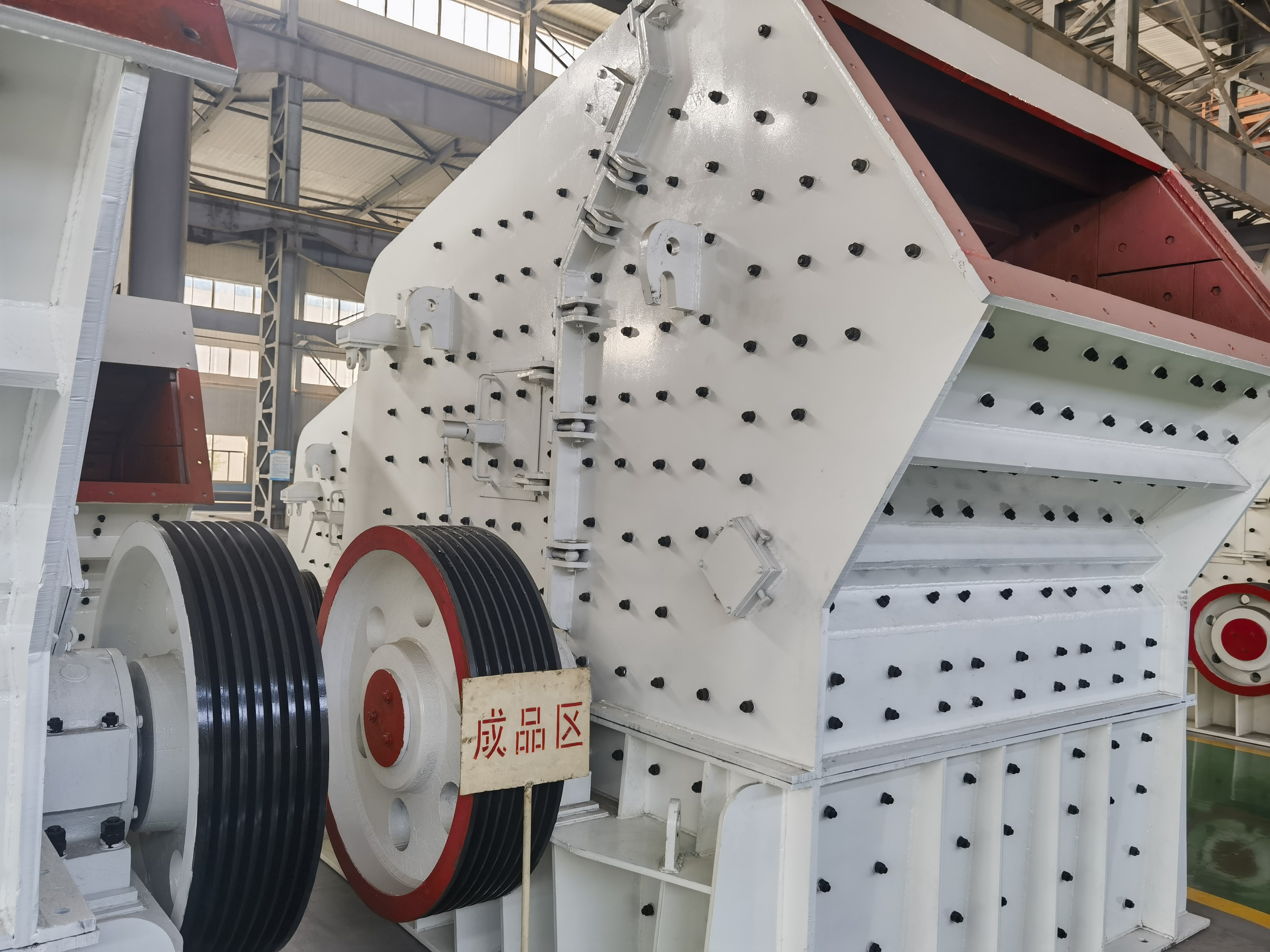

When the machine is working, the motor drives the rotor shaft through the V-belt, the material is crushed by the high-speed impact of the plate hammer on the rotor, and is thrown to the counterattact elbow plate to be crushed again, and then bounced back from the impact surface to the plate hammer area to be re-crushed, and the process is repeated until the material is crushed to the required size, the material is crushed form the first inlet to the first crushing chamber. Then enter into the second crushing chamber, when the size of crushed ore is less than the gap between the hammer head and the counterattack plate, then it will be discharged from the lower part of the machine, i.e., it is the crushed product.